A kind of wear-resistant PA/ASA alloy and preparation method thereof

An alloy, PA66 technology, applied in the field of wear-resistant PA/ASA alloy and its preparation, can solve the problems of limited alloy use, solubility parameters, polarity and crystallinity difference, and poor mechanical properties, so as to improve tensile strength, Effect of inhibiting photooxidation process and improving anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

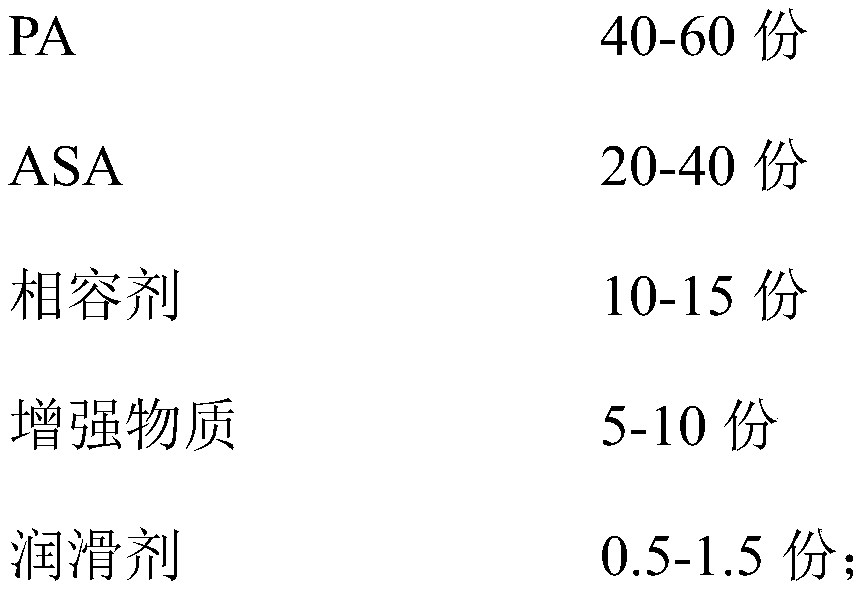

[0058] This embodiment provides a wear-resistant PA / ASA alloy, the composition of which is as follows in parts by mass:

[0059]

[0060] Wherein, the reinforcing material is non-surface-modified montmorillonite, and the mesh number is 500 mesh.

[0061] The preparation method of the wear-resistant PA / ASA alloy provided in this embodiment is as follows:

[0062] Add the above-mentioned components into a high-speed mixer and mix for 10 minutes, and then feed the mixed material of each component into a twin-screw extruder. The twin-screw extruder includes the first zone, the second zone, the third zone, the fourth zone, the fifth zone, the sixth zone, the seventh zone, the eighth zone, the ninth zone and the machine head connected in sequence. The mixed materials pass through each zone in turn, and the first zone The temperature is 200°C, the temperature in the second zone is 210°C, the temperature in the third zone is 220°C, the temperature in the fourth zone is 230°C, the ...

Embodiment 2

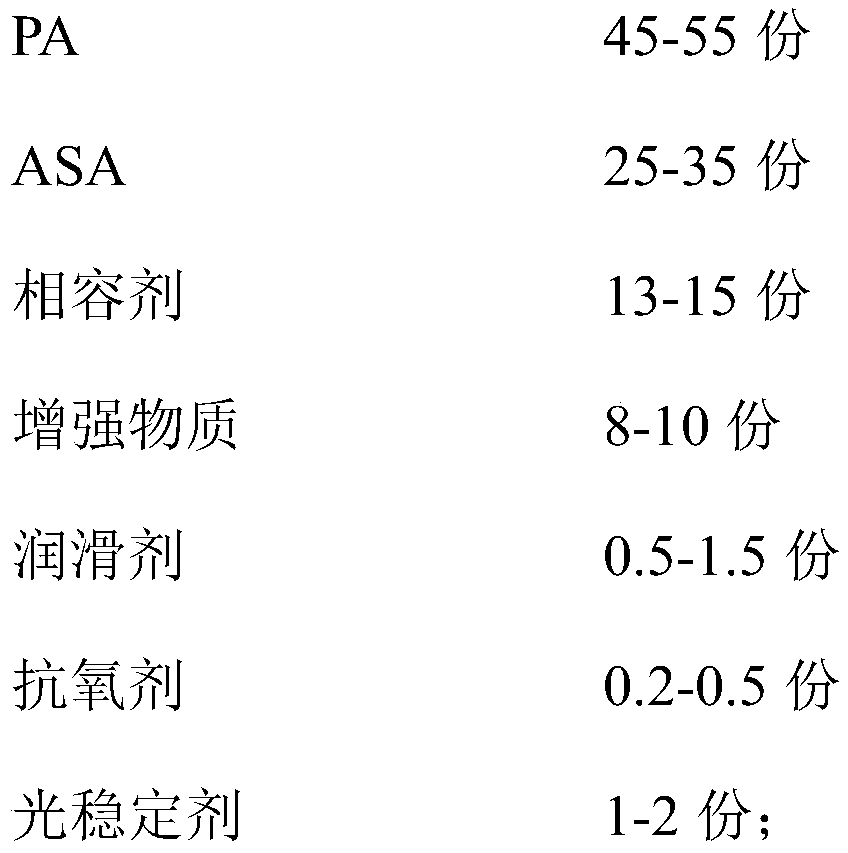

[0064] This embodiment provides a wear-resistant PA / ASA alloy, the composition of which is as follows in parts by mass:

[0065]

[0066] Wherein, the reinforcing material is non-surface-modified montmorillonite, and the mesh number is 450 mesh.

[0067] The preparation method of the wear-resistant PA / ASA alloy provided in this embodiment is as follows:

[0068]Add the above-mentioned components into a high-speed mixer and mix for 5 minutes, and then feed the mixed material of each component into a twin-screw extruder. The twin-screw extruder includes the first zone, the second zone, the third zone, the fourth zone, the fifth zone, the sixth zone, the seventh zone, the eighth zone, the ninth zone and the machine head connected in sequence. The mixed materials pass through each zone in turn, and the first zone The temperature is 200°C, the temperature in the second zone is 210°C, the temperature in the third zone is 220°C, the temperature in the fourth zone is 230°C, the te...

Embodiment 3

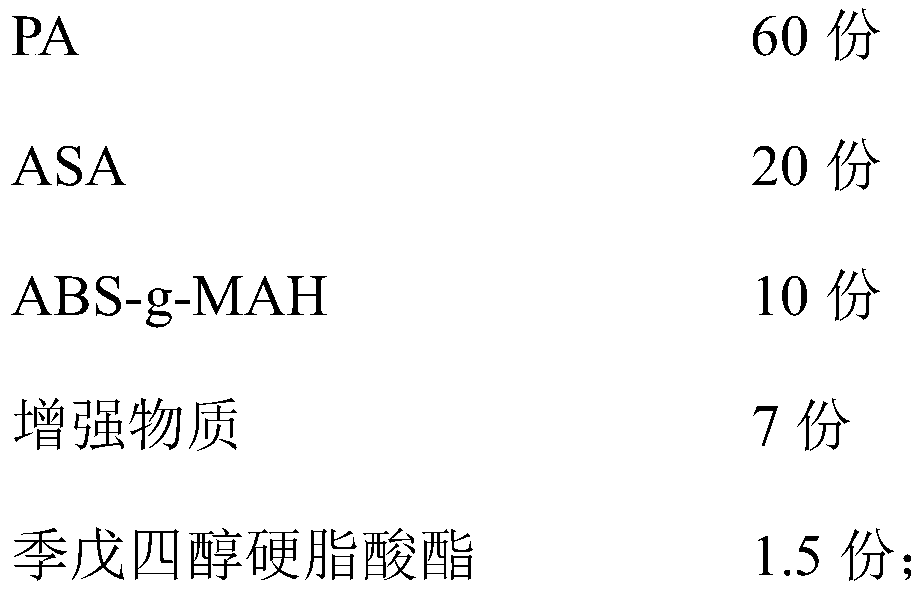

[0070] This embodiment provides a wear-resistant PA / ASA alloy, the composition of which is as follows in parts by mass:

[0071]

[0072] Wherein, the reinforcing material is non-surface-modified montmorillonite, and the mesh number is 400 mesh.

[0073] The preparation method of the wear-resistant PA / ASA alloy provided in this embodiment is as follows:

[0074] Add the above-mentioned components into a high-speed mixer and mix for 8 minutes, and then feed the mixed material of each component into a twin-screw extruder. The twin-screw extruder includes the first zone, the second zone, the third zone, the fourth zone, the fifth zone, the sixth zone, the seventh zone, the eighth zone, the ninth zone and the machine head connected in sequence. The mixed materials pass through each zone in turn, and the first zone The temperature is 200°C, the temperature in the second zone is 210°C, the temperature in the third zone is 220°C, the temperature in the fourth zone is 230°C, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com