Fluorine-substituted vinyl polymer resin composition, prepreg and laminate

A technology of vinyl polymer and resin composition, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., which can solve the problems of difficult to make high-layer PCB boards, difficult control of substrate thickness uniformity, original coating The layer is easy to fall off and other problems, and the modulation is simple and easy, the reliability is low, and the effect of excellent dielectric properties is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4、 comparative example 1-2

[0051] In Examples 1-4 and Comparative Examples 1-2, the components are as shown in Table 1.

[0052] Table 1 Embodiment 1-4 and comparative example 1-2 component table

[0053]

[0054]

[0055] Table 2 shows the properties of the glue solutions prepared in Examples 1-4 and Comparison 1-2.

[0056] Table 2 Performance table

[0057]

[0058] As shown in Table 2, the fluorine-substituted vinyl polymer resin composition provided in Example 1 has a glass transition temperature of 175°C, a thermal decomposition temperature of 350°C, and a delamination time of more than 30 minutes at 288°C , the peel strength is 6.2lb / in, under the condition of 10GHz D k 、D f are 2.5 and 0.005, respectively.

[0059] Similarly, the fluorine-substituted vinyl polymer resin composition provided in Example 3 has a glass transition temperature of 176°C, a thermal decomposition temperature of 352°C, and a delamination time of more than 30 minutes at 288°C, and the peel strength It is 6lb / ...

Embodiment 5

[0064] A prepreg is prepared by impregnating the above-mentioned fluorine-substituted vinyl polymer resin composition into a base material and semi-curing or specially curing the impregnated base material.

[0065] The fluorine-substituted vinyl polymer resin composition has the above-mentioned structural formula (1), and its particle diameter can be less than 100 microns as mentioned above, or less than 90 microns, or less than 80 microns. , or less than 70 microns, or less than 60 microns, or less than 50 microns.

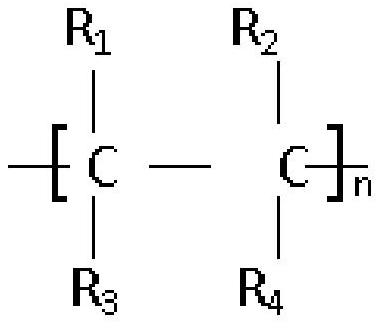

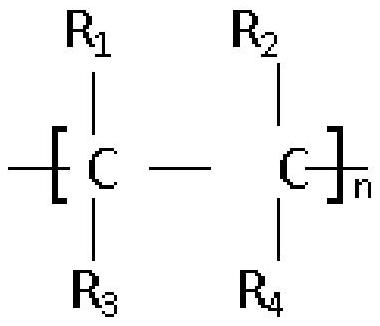

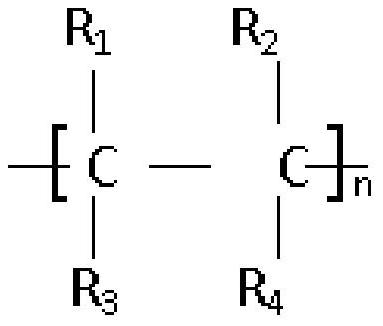

[0066] The substituent R of the fluorine-substituted vinyl polymer resin composition 1 ,R 2 ,R 3 ,R 4 At least one is a fluorine atom. In some other embodiments, the fluorine-substituted vinyl polymer resin composition is composed of one or two of polyvinyl fluoride, polytetrafluoroethylene, polyvinylidene fluoride, polytrifluoroethylene and A mixture of its various forms.

[0067] The number n of repeating units of the fluorine-substituted vinyl polymer res...

Embodiment 6

[0071] The prepreg obtained by impregnating the above-mentioned fluorine-substituted vinyl polymer resin composition into the base material to be semi-cured or specially cured is laminated with copper foil to obtain a laminate. The fluorine-substituted vinyl polymer resin composition used in the laminate has a structure such as formula (1), and its maximum particle size can be selected to be less than 100 microns, or less than 90 microns, or less than 80 microns, Or less than 70 microns, or less than 60 microns, or less than 50 microns.

[0072] The fluorine-substituted vinyl polymer resin composition substituent R 1 ,R 2 ,R 3 ,R 4 At least one is a fluorine atom. In some other embodiments, the fluorine-substituted vinyl polymer resin composition is composed of one or two of polyvinyl fluoride, polytetrafluoroethylene, polyvinylidene fluoride, polytrifluoroethylene and A mixture of its various forms.

[0073] The number n of repeating units of the fluorine-substituted vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com