A kind of preparation method of anti-aging sealant for automobile

An aging-resistant and sealant technology, applied in the field of composite materials, can solve the problems of poor high temperature and aging resistance, short service life, etc., and achieve the effect of stable performance and high synthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

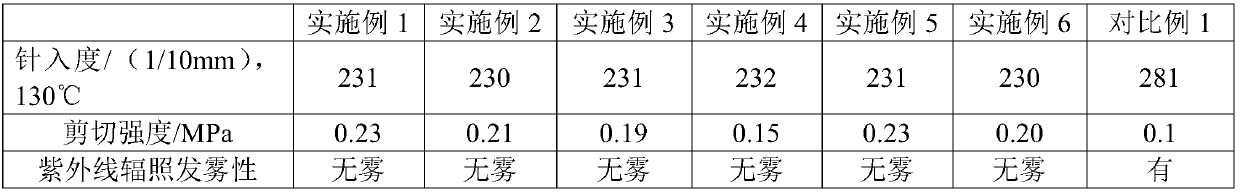

Examples

Embodiment 1

[0025] A preparation method of anti-aging sealant for automobiles, comprising the following steps:

[0026] (1) At -60°C, using methyl chloride as a solvent, isobutylene as the first monomer, p-methylstyrene as the second monomer, and aging and complexing with HCl and aluminum trichloride for 30 minutes to obtain Initiate the system, and add n-propanol or monoethanolamine as the third component, the third component is added to the reactor along with the polymerized monomer when the monomer is fed, and the cationic slurry copolymerization is carried out for 40 hours to obtain poly Isobutylene-based random copolymer; wherein, in the reaction system, the total mass concentration of isobutylene and p-methylstyrene is 45wt%, and the mass ratio of isobutylene and p-methylstyrene is 2.5:1; n-propanol or monoethanolamine The concentration is 1×10 - 6 mol / L; the molar ratio of n-propanol or monoethanolamine to aluminum chloride is 18:1, and the molar ratio of HCl to aluminum chloride...

Embodiment 2

[0031] A preparation method of anti-aging sealant for automobiles, comprising the following steps:

[0032] (1) At -100°C, using methyl chloride as a solvent, isobutylene as the first monomer, and o-methylstyrene as the second monomer, aging and complexing with water and alkyl aluminum chloride for 5 minutes to prepare The initiation system is obtained, and isobutanol or diethanolamine is added as the third component. When the monomer is fed, the third component is added to the reactor along with the polymerized monomer, and is copolymerized by cationic slurry for 40 hours to obtain Polyisobutylene-based random copolymer; wherein, in the reaction system, the total mass concentration of isobutylene and o-methylstyrene is 10wt%, and the mass ratio of isobutylene and o-methylstyrene is 0.5:1; isobutanol or diethanolamine The concentration is 1×10 -2 mol / L; the molar ratio of isobutanol or diethanolamine to alkyl aluminum chloride is 6:1, and the molar ratio of water to alkyl alu...

Embodiment 3

[0037] A preparation method of anti-aging sealant for automobiles, comprising the following steps:

[0038](1) At -70°C, with methyl chloride as the solvent, isobutylene as the first monomer, and m-ethylstyrene as the second monomer, dicyclohexylcarbodiimide and alkylaluminum chloride are used to Compounding for 10 minutes to prepare the initiation system, and adding isopropanol or diethanolamine as the third component, the third component is added to the reactor along with the polymerized monomer when the monomer is fed, and is co-polymerized by cationic slurry. Polymerize for 50 hours to obtain a polyisobutylene-based random copolymer; wherein, in the reaction system, the total mass concentration of isobutylene and m-ethylstyrene is 15 wt%, and the mass ratio of isobutylene and m-ethylstyrene is 0.9:1; The concentration of isopropanol or diethanolamine is 1 x 10 -3 mol / L; the molar ratio of isopropanol or diethanolamine to alkyl aluminum chloride is 10:1, and the molar rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com