High-efficiency flame-retardant slow-resilient polyurethane sponge and preparation method thereof

A polyurethane sponge and slow rebound technology, applied in the field of sponge products, can solve the problems of high difficulty of flame retardant effect, poor air permeability of slow rebound, affecting the flame retardant effect, etc., to reduce material cost, efficient flame retardant effect, good physical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of high-efficiency flame-retardant slow-rebound polyurethane sponge adopts the following steps:

[0032] (1) Weigh polyether polyols and polymer polyols in parts by weight, the total number of parts is 100 parts, add 0.5 parts-3.0 parts of foam stabilizers, catalysts 0.1 parts-1.0 parts, expandable graphite 5 parts- 30 parts, liquid flame retardant 10-20 parts, liquid reactive flame retardant 0-15 parts, foaming agent 1.0-4.0 parts, alcohol amine chain extender 0.5-3.0 parts, melamine 0-20 parts , carry out high-speed stirring at room temperature with a stirring speed of 2000r / min-4000r / min to obtain a reaction mixture;

[0033] (2) Introduce 30-70 parts of modified MDI into the above reaction mixture, stir at a high speed at 20°C-25°C and react for 5s-10s, then introduce into the prepared mold and mature at room temperature to obtain a high-efficiency resistance Combustible slow rebound polyurethane sponge products.

[0034] When the above-ment...

Embodiment approach 1

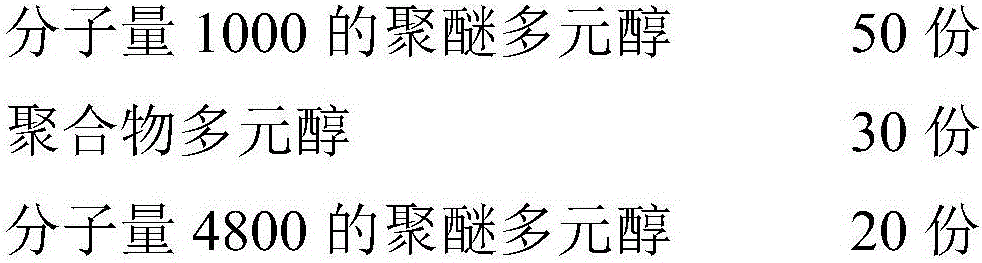

[0036] The formula of high-efficiency flame-retardant polyurethane sponge has the following raw materials in parts by weight:

[0037]

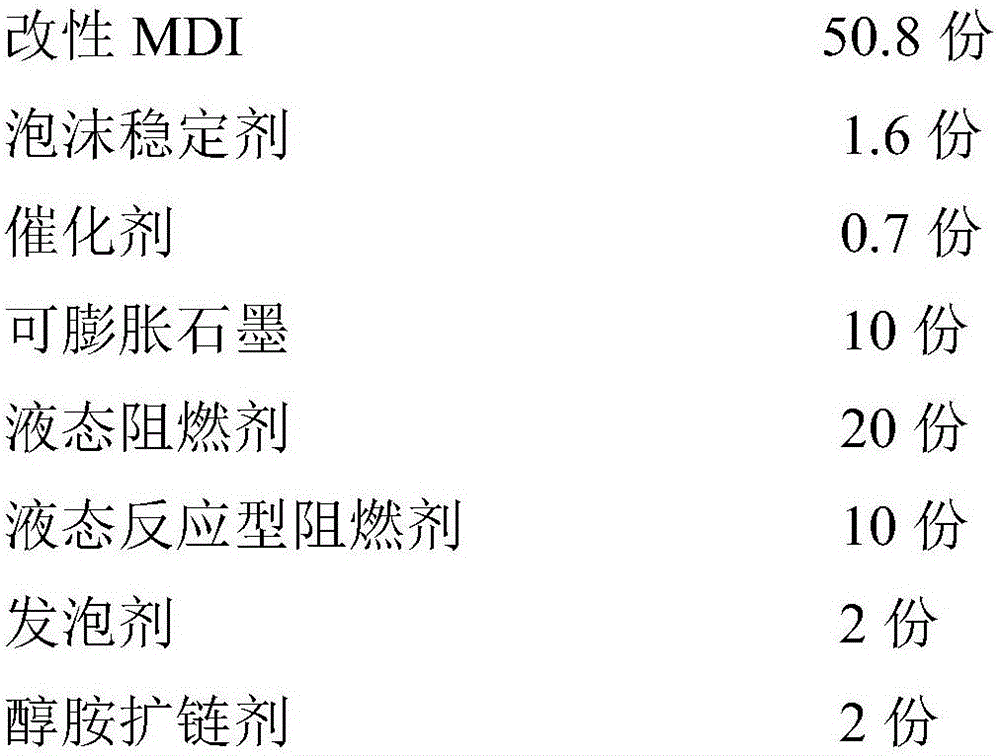

[0038]

[0039] The foam stabilizer preferably adopts L-658 of Momentive High-tech Materials Co., Ltd., and this silicone oil has certain flame retardant properties, and is more suitable for the present invention.

[0040] The preparation method of the above-mentioned high-efficiency flame-retardant polyurethane sponge adopts the following steps:

[0041] (1) Take by weight 50 parts of polyether polyols with a molecular weight of 1000, 30 parts of polymer polyols, and 20 parts of polyether polyols with a molecular weight of 4800, the total number of parts is 100 parts, and continue to add foam stabilizers 1.6 parts, 0.7 parts of catalyst, 10 parts of expandable graphite, 20 parts of liquid flame retardant, 10 parts of liquid reactive flame retardant, 2 parts of foaming agent, 2 parts of alcohol amine chain extender, at room temperature ...

Embodiment approach 2

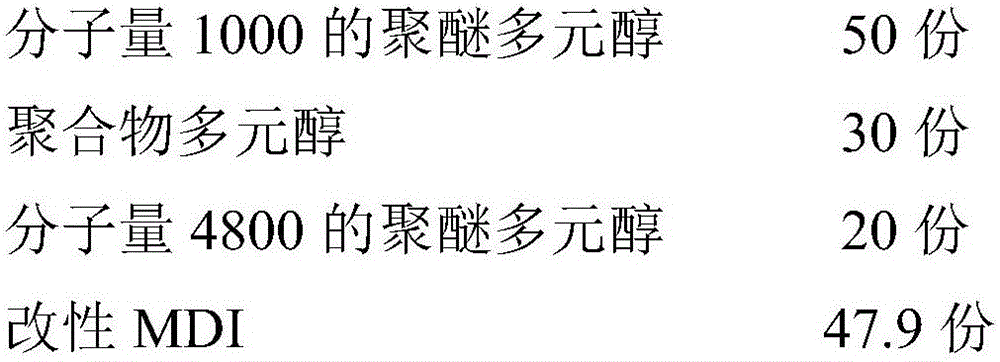

[0045] The formula of high-efficiency flame-retardant polyurethane sponge has the following raw materials in parts by weight:

[0046]

[0047]

[0048] The foam stabilizer preferably adopts L-658 of Momentive High-tech Materials Co., Ltd., and this silicone oil has certain flame retardant properties, and is more suitable for the present invention.

[0049] The preparation method of the above-mentioned high-efficiency flame-retardant polyurethane sponge adopts the following steps:

[0050] (1) Take by weight 50 parts of polyether polyols with a molecular weight of 1000, 30 parts of polymer polyols, and 20 parts of polyether polyols with a molecular weight of 5000, the total number of parts is 100 parts, and continue to add foam stabilizers 1.3 parts, 0.7 parts of catalyst, 20 parts of expandable graphite, 20 parts of liquid flame retardant, 10 parts of liquid reactive flame retardant, 1.8 parts of foaming agent, 2 parts of alcohol amine chain extender, at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com