Additive for increasing content of polysaccharide in tobacco leaf planting

A polysaccharide content and additive technology, applied in the field of additives for tobacco leaf planting, can solve the problems of fertilizer soil acidification, organic matter content decline, hardening, etc., and achieve the effect of solving waste residue pollution, increasing crystallinity, and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

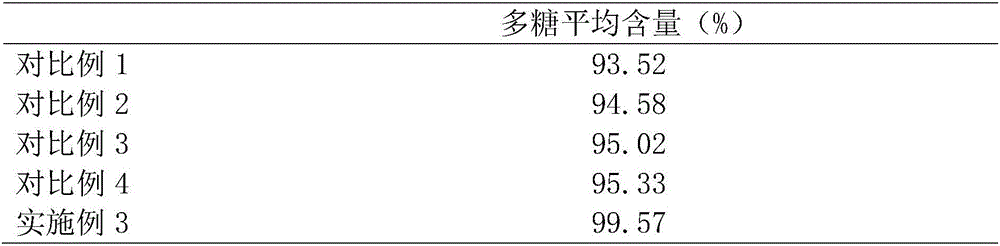

Examples

Embodiment 1

[0024] An additive for tobacco leaf planting capable of increasing the polysaccharide content is obtained by the following preparation method:

[0025] ① Cleaning: Wash the discarded lychee skin with water to remove the sediment and impurities on the surface of the lychee skin;

[0026] 2. Drying: drying the lychee skin obtained in step 1, and pulverizing it with a ball mill to obtain 80 orders of litchi skin coarse powder;

[0027] ③Low-temperature pulverization: The litchi skin coarse powder obtained in step ② is subjected to low-temperature freezing at 0°C and low-temperature sublimation drying in sequence, then uses liquid nitrogen as the grinding medium, and uses an ultra-low temperature pulverizer for low-temperature pulverization at -80°C;

[0028] ④High-pressure homogenization: Add 5 times the weight of pure water to the material obtained in step ③ and mix evenly, then add it to a high-pressure homogenizer for processing, 10000psi, 20min, centrifuge, 8000r / min, 10min, ...

Embodiment 2

[0030] An additive for tobacco leaf planting capable of increasing the polysaccharide content is obtained by the following preparation method:

[0031] ① Cleaning: Wash the discarded lychee skin with water to remove the sediment and impurities on the surface of the lychee skin;

[0032] 2. Drying: drying the lychee skin obtained in step 1, and pulverizing it with a ball mill to obtain 100 order litchi skin coarse powder;

[0033] ③Low-temperature pulverization: The litchi peel coarse powder obtained in step ② is subjected to low-temperature freezing at -10°C and sublimation drying at low temperature in sequence, and then liquid nitrogen is used as the grinding medium, and low-temperature pulverization is carried out at -100°C with an ultra-low temperature pulverizer;

[0034] ④High-pressure homogenization: Add 6 times the weight of pure water to the material obtained in step ③ and mix evenly, then add it to a high-pressure homogenizer for processing, 15000psi, 15min, centrifug...

Embodiment 3

[0036] An additive for tobacco leaf planting capable of increasing the polysaccharide content is obtained by the following preparation method:

[0037] ① Cleaning: Wash the discarded lychee skin with water to remove the sediment and impurities on the surface of the lychee skin;

[0038] 2. Drying: drying the lychee skin obtained in step 1, and pulverizing it with a ball mill to obtain 100 order litchi skin coarse powder;

[0039] ③Low temperature pulverization: The litchi peel coarse powder obtained in step ② is subjected to low-temperature freezing at -18°C and sublimation drying at low temperature in sequence, then liquid nitrogen is used as the grinding medium, and low-temperature pulverization is carried out at -120°C with an ultra-low temperature pulverizer;

[0040] ④High-pressure homogenization: Add 5 times the weight of pure water to the material obtained in step ③ and mix evenly, then add it to a high-pressure homogenizer for processing, 18000psi, 10min, centrifuge, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com