Method used for preparing test dies with recycled aggregate concrete

A technology of recycled aggregates and test molds, applied in molds, manufacturing tools, sustainable waste treatment, etc., can solve the problems of waste of resources, rough surface of molds, small use range, etc., and achieve resource saving, high strength, and convenient demoulding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

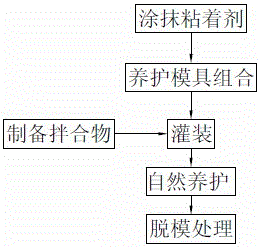

[0040] Such as Figure 1-4 Shown, a kind of method that utilizes recycled aggregate concrete to prepare test mould, comprises the mold combination that is used to prepare mould, is provided with preparation space in said mold combination, and said preparation space matches the size of standard mould, and said standard mold Used to prepare standard test blocks, including the following steps:

[0041] Step 1: apply the adhesive: apply the adhesive evenly in the preparation space;

[0042] Step 2: maintaining the mold assembly: naturally curing the mold assembly coated with adhesive, so that the adhesive forms a protective film on the inner wall of the mold assembly;

[0043] Step 3: preparing the mixture: using the recycled aggregate concrete to prepare the mixture;

[0044] Step 4: Filling: inject the mixture into the preparation space with a protective film on the inner wall;

[0045] Step 5: natural curing: natural curing of the mold combination with the mixture;

[0046]...

Embodiment 2

[0060] Such as Figure 1-4 As shown, in the method for preparing a test mold using recycled aggregate concrete listed in this embodiment, the preparation of 1L mixture is taken as an example, and the specific steps are as follows:

[0061] Step 1: apply the adhesive: melt the solid paraffin, and apply it evenly on the inner surface of the preparation space;

[0062] Step 2: maintaining the mold assembly: naturally curing the mold assembly coated with solid paraffin, so that the adhesive forms a protective film on the inner wall of the mold assembly;

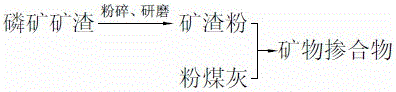

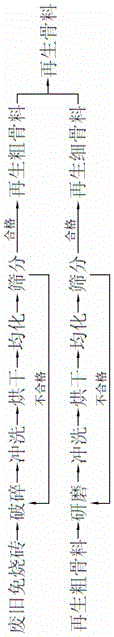

[0063] Step 3: Prepare the mixture: prepare the mixture by using recycled aggregate concrete, including the following steps: Step 31: Prepare recycled aggregate; use waste unburned bricks to sequentially undergo crushing, washing, drying, homogenizing, and screening, The obtained particles with a particle size of 5-10mm are used as the recycled coarse aggregate. Take 120g of the recycled coarse aggregate for later use, and anoth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com