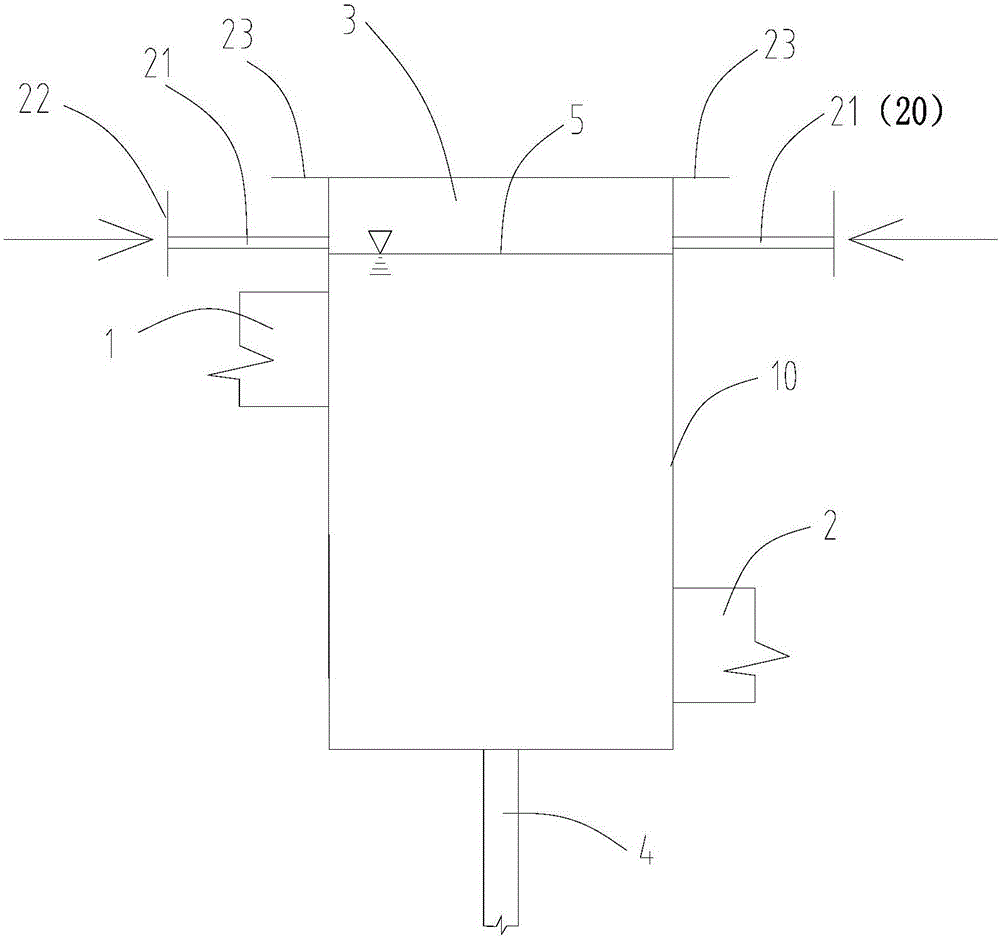

Platinum channel mixing barrel and platinum channel mixing barrel device

A platinum channel and mixing tank technology, applied in the field of glass substrate production equipment, can solve problems affecting the normal operation of the production line, temperature influence, and restricting the improvement of the glass yield rate of the production line substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

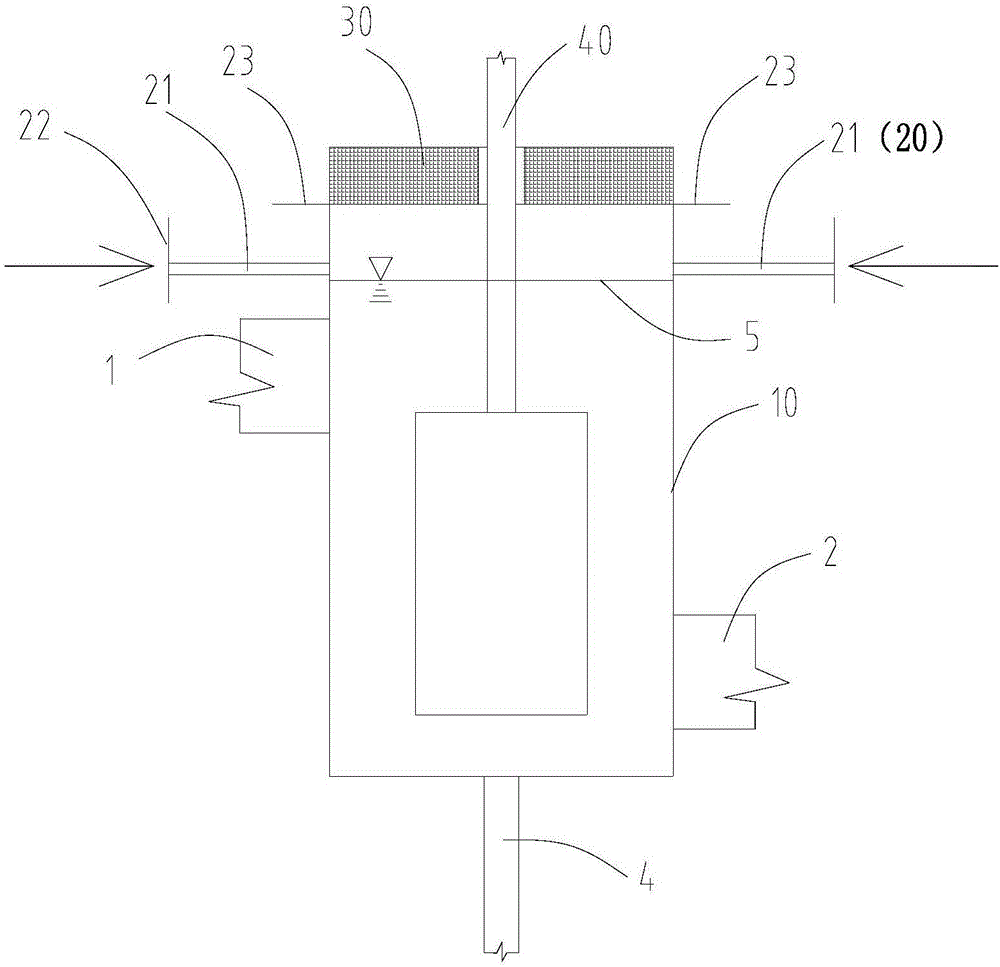

[0056] use figure 2 The platinum channel mixing barrel device shown is tested. The inert gas is nitrogen, the temperature when the inert hot gas enters the space above the free liquid level is 1000℃, and the flow rate is 2m 3 / h, the flow of glass liquid in the mixing barrel is 400kg / h. The stirring barrel body 10, the stirring rod 40, the first electrode 22, the second electrode 23, the discharge port 4, and the inert gas blowing pipe 21 are all made of platinum rhodium alloy. The inert gas blowing pipe 21 is a circular pipe with an inner diameter of 16 mm. The test time is 10 months.

experiment example 2

[0057] Experimental example 2, using figure 2 The platinum channel mixing barrel device shown is tested. The inert gas is nitrogen, the temperature when the inert hot gas enters the space above the free liquid level is 1200℃, and the flow rate is 5m 3 / h, the flow of glass liquid in the mixing barrel is 400kg / h. The stirring barrel body 10, the stirring rod 40, the first electrode 22, the second electrode 23, the discharge port 4, and the inert gas blowing pipe 21 are all made of platinum rhodium alloy. The inert gas blowing pipe 21 is a circular pipe with an inner diameter of 16 mm. The test time is 10 months.

experiment example 3

[0058] Experimental example 3, using figure 2 The platinum channel mixing barrel device shown is tested. The inert gas is nitrogen, the temperature when the inert hot gas enters the space above the free liquid surface is 1300℃, and the flow rate is 8m 3 / h, the flow of glass liquid in the mixing barrel is 400kg / h. The stirring barrel body 10, the stirring rod 40, the first electrode 22, the second electrode 23, the discharge port 4, and the inert gas blowing pipe 21 are all made of platinum rhodium alloy. The inert gas blowing pipe 21 is a circular pipe with an inner diameter of 16 mm. The test time is 10 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com