Method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide

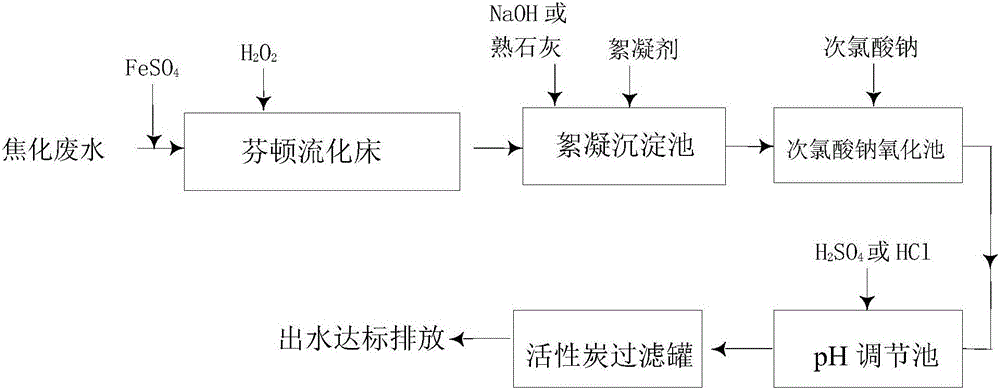

A technology for advanced treatment and coking wastewater, which is applied in special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc. It can solve the problems of high concentration of effluent pollutants, low efficiency of advanced treatment of coking wastewater, and failure to meet discharge standards and other problems, to achieve the effect of high reaction efficiency, reduced infrastructure investment, and less mud production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] First, the coking plant effluent (that is, coking wastewater, selected from the biochemical effluent of a coking plant, COD: 290mg / L, cyanide 10mg / L, chromaticity 600 times) is raised to the Fenton fluidized bed, and ferrous sulfate is added 1500mg / L (in the mixed aqueous solution containing ferrous sulfate, the mass concentration of ferrous sulfate is 25%, the mass concentration of sulfuric acid is 3%, and the balance is water), and carry out according to the ratio that hydrogen peroxide addition is 150mg / L In conversion, add the corresponding amount of hydrogen peroxide to the Fenton fluidized bed, add the mixed aqueous solution containing ferrous sulfate, the pH of the solution is 3.3, and the effective reaction time is 20 minutes; after the Fenton reaction, the effluent enters the flocculation sedimentation tank, and hydrogenation and oxidation Adjust the pH value of the reaction solution to 10 with sodium aqueous solution, add PAM 20mg / L, react for 10 minutes, and ...

Embodiment 2

[0056] The coking wastewater (selected from the biochemical effluent of a coking plant, COD: 240mg / L, cyanide 8.6mg / L, color 550 times) was raised to the Fenton fluidized bed, and ferrous sulfate 1000mg / L (containing sulfuric acid In the mixed aqueous solution of ferrous iron, the mass concentration of ferrous sulfate is 22%, the mass concentration of sulfuric acid is 1.5%, and the balance is water), and convert according to the ratio that the hydrogen peroxide addition is 200mg / L, add the corresponding amount Hydrogen peroxide was added to the Fenton fluidized bed. After adding the mixed aqueous solution containing ferrous sulfate, the pH value of the solution was 4.0, and the effective reaction time was 30 minutes. value to 11, add PAM 15mg / L, reaction time 15 minutes, sedimentation 30 minutes; flocculation precipitation effluent enters the sodium hypochlorite oxidation tank, the mass ratio of sodium hypochlorite dosage to cyanide in wastewater is 30:1 (sodium hypochlorite do...

Embodiment 3

[0058] The coking wastewater (selected from the biochemical effluent of a coking plant, COD: 150mg / L, cyanide 5.9mg / L, color 450 times) was raised to the Fenton fluidized bed, and ferrous sulfate 1300mg / L (containing sulfuric acid In the mixed aqueous solution of ferrous iron, the mass concentration of ferrous sulfate is 24%, the mass concentration of sulfuric acid is 2%, and the balance is water), and convert according to the ratio that the hydrogen peroxide addition is 300mg / L, add corresponding amount Hydrogen peroxide was added to the Fenton fluidized bed. After adding the mixed aqueous solution containing ferrous sulfate, the pH value of the solution was 3.4, and the effective reaction time was 30 minutes. value to 12, add PAM dosage 30mg / L, react for 15 minutes, and settle for 30 minutes; the flocculated sedimentation water enters the sodium hypochlorite reaction tank, and the mass ratio of sodium hypochlorite dosage to cyanide in wastewater is 25:1 (sodium hypochlorite d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com