Double-layer composite type aeration machine

A composite aerator technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to deep aeration, low aeration efficiency, and inconspicuous fragmentation of air bubbles And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

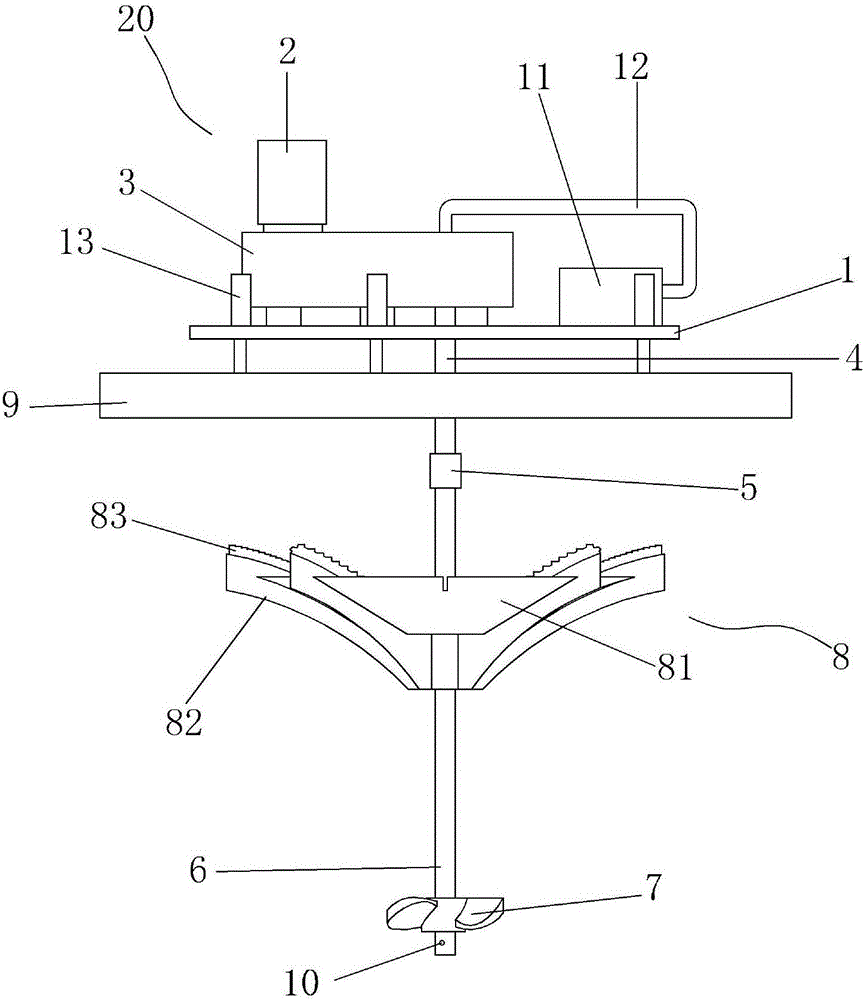

[0011] Such as figure 1 As shown, a double-layer composite aerator according to the present invention includes a base 1, and the base 1 is provided with a hydraulic propulsion device 20 composed of a motor 2 and a reducer 3, and the reducer 3 is provided with a reducer output The shaft 4 and the output shaft 4 of the reducer are connected to the main shaft 6 through a coupling 5, and the main shaft 6 is provided with an air guide cavity (not shown in the drawings), and the lower part of the main shaft 6 is provided with a spiral thrust piece 7 and an air hole 10. An inverted umbrella impeller 8 is provided on the upper part of the main shaft 6, and a compressed air pump 11 is provided on the base 1. The compressed air pump 11 is connected with an air guide tube 12, and the air guide tube 12 is inserted into the air g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com