Safe process and system for producing and purifying hydrogen cyanide

A hydrogen cyanide and safe technology, applied in the field of high-purity liquid hydrogen cyanide, can solve the problems of less research on purification and purification, and achieve the effects of good market promotion and application value, low pressure and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below.

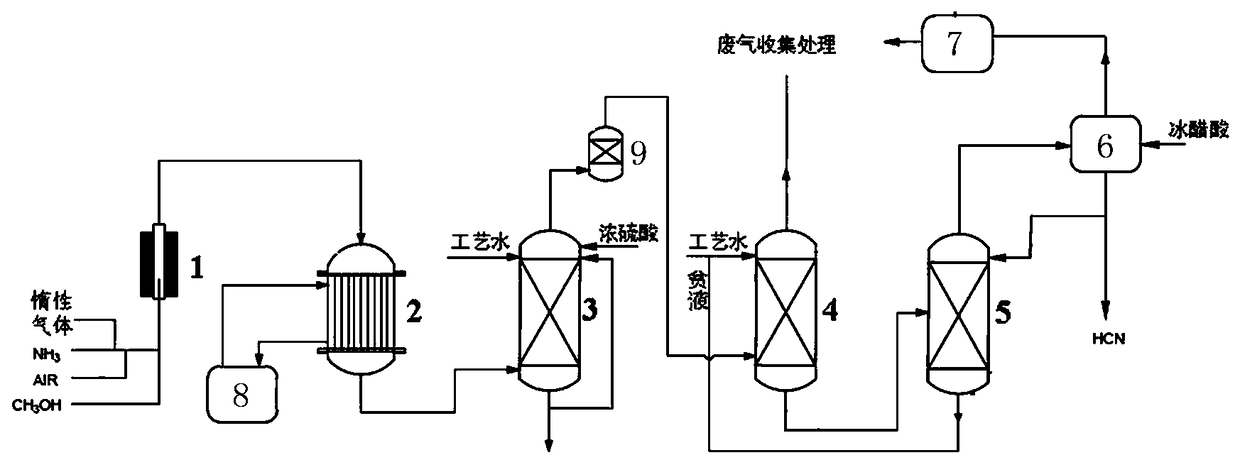

[0025] Preparation of the present invention, purification process and related devices are as follows, as figure 1 Shown:

[0026] (1) Raw material mixing and preheating device:

[0027] After the ammonia gas is preheated and vaporized, it is first mixed with an inert gas and then mixed with compressed air. The ammonia gas preheating temperature is 20~40°C, and the compressed air pressure is 0.1~0.4Mpa. The mixed gas enters the tube furnace from around the methanol feed nozzle, pushes the methanol upward to vaporize and mixes with methanol. Ammonia is mixed with inert gas and air successively, and then mixed with methanol. The substance ratio of ammonia to methanol in the mixed gas is 1.02~1.10:1, the ratio of ammonia to air is 0.1~0.12:1, and the volume of the mixed inert gas accounts for 12~18% of the total volume of the mixture , to reduce the explosive characteristics of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com