Machining and feeding mechanism of suspension frame assembly of electric vehicle

An electric vehicle and machining technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy deviation, high risk, production accidents, etc., to reduce the risk of accidents, stabilize the feeding height adjustment, Avoid the effects of stamping operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

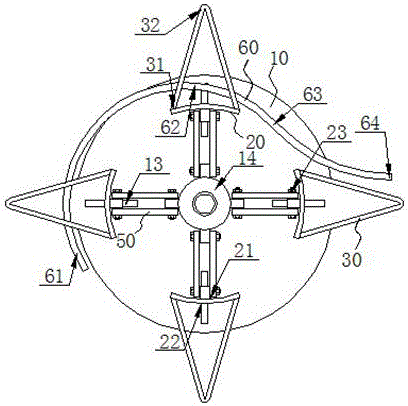

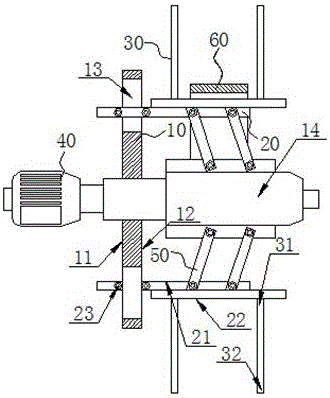

[0014] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0015] Such as Figure 1 to Figure 2 As shown, a kind of electric vehicle suspension component machined feeding mechanism includes a pick-up rotating disc 10, and the two sides of the pick-up rotating disc 10 are respectively a driving connection surface 11 and a pick-up operation surface 12. On the pick-up operation surface 12 of the rotating disc 10, several pick-up operation support arms 20 are arranged, and each of the pick-up operation support arms 20 includes a pick-up support towards the axis of the pick-up rotation disc 10. The inner side 21 of the arm and the outer side 22 of the pick-up support arm facing away from the axis of the pick-up rotating disk 10, each of the pick-up support arm outer sides 22 of the pick-up operation support arm 20 is provided with two V-shaped pick-up connecting rod 30, the two ends of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com