On-stream method of residual oil hydrogenation process

A technology for residual oil hydrogenation and process, which is applied in the directions of chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., and can solve the problems of on-time start-up of residual oil hydrogenation units, increased production costs, and increased processing costs, etc. problems, to achieve the effect of reducing human body damage, reducing usage, and uniform pre-vulcanization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

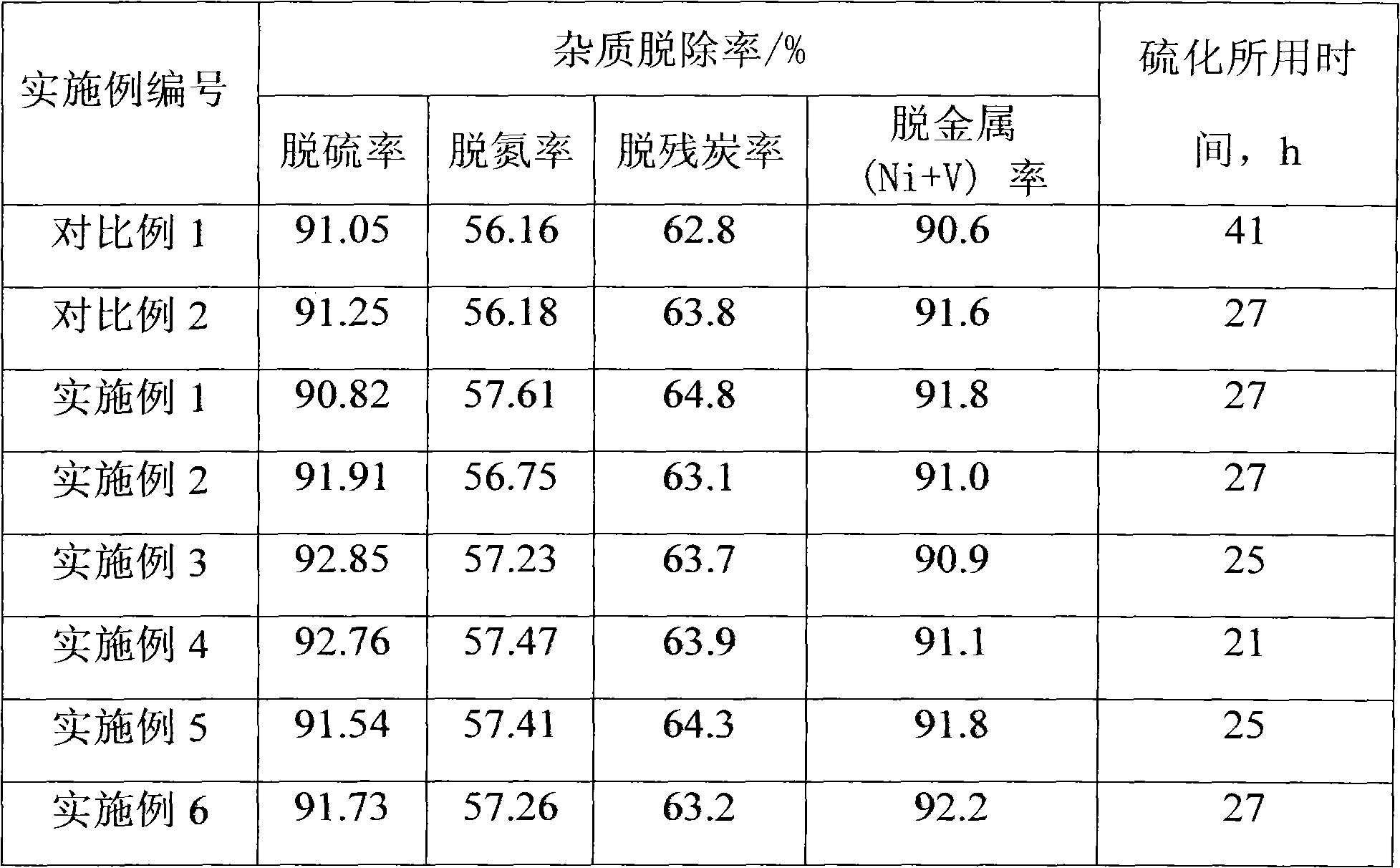

Examples

Embodiment 1

[0050] 50g of FZC-102 and 100g of FZC-30 are respectively immersed in 10g and 15g of organic solvent (organic solvent is coking kerosene fraction), the proportion of carbon atoms in the organic solvent is not less than 50%, and the immersion time is 1 hour. The vulcanizing agent used in the FZC-102 catalyst is 10g of elemental sulfur and 2.5g (NH 4 ) 2 S mixture, the vulcanizing agent that FC-30 catalyst uses is elemental sulfur 20g and 5g (NH 4 ) 2 S mixture. The impregnated FZC-102 and FZC-30 were mixed with corresponding vulcanizing agents respectively, and treated at 170°C for 3 hours, and cooled naturally. The obtained presulfurized catalyst, presulfurized FZC-102 catalyst and presulfurized FZC-30 catalyst, oxidized state FZC-20 and oxidized state FZC-40 catalyst are divided into small-sized reactors (contact FZC-102 earlier by reaction materials, Then contact with FZC-20 and contact with FZC-30, and finally contact with FZC-40 in the order of filling, other embodimen...

Embodiment 2

[0052] 50g of FZC-102 and 100g of FZC-40 are respectively immersed in 10g and 15g of organic solvent (organic solvent is coking kerosene fraction), the ratio of carbon number 9 to 12 in the organic solvent is not less than 50%, and the immersion time is 1 hour. The vulcanizing agent used in the FZC-102 catalyst is 10g of elemental sulfur and 2.5g (NH 4 ) 2 S mixture, the vulcanizing agent that FC-40 catalyst uses is the (NH 4 ) 2 S mixture. The impregnated FZC-102 and FZC-40 were mixed with corresponding vulcanizing agents respectively, and treated at 170°C for 3 hours, and cooled naturally. The obtained presulfided catalyst, presulfurized FZC-102 catalyst and presulfided FZC-40 catalyst, oxidized state FZC-20 and oxidized state FZC-30 catalyst are divided into small reactors according to the order of embodiment 1, and the airtightness is qualified. Start to raise the temperature at 20°C / h, rise to 220°C, and keep the temperature constant for 8 hours. End the constant tem...

Embodiment 3

[0054] 50g of FZC-102 and 100g of FZC-30 are respectively immersed in 15g and 20g of organic solvents (organic solvents are coking kerosene fractions), the proportion of carbon atoms 9-12 in the organic solvents is not less than 50%, and the immersion time is 1 hour. The vulcanizing agent that FZC-102 catalyst uses is elemental sulfur 15g and 3.5g (NH 4 ) 2 S mixture, the vulcanizing agent that FC-30 catalyst uses is elemental sulfur 15g and 4g (NH 4 ) 2 S mixture. The impregnated FZC-102 and FZC-30 were mixed with corresponding vulcanizing agents respectively, and treated at 170°C for 3 hours, and cooled naturally. The obtained presulfided catalyst, the presulfurized FZC-102 catalyst, the presulfided FZC-30 catalyst, the oxidized state FZC-20 and the oxidized state FZC-40 catalyst are divided into small reactors according to the order of Example 1, and the airtightness is qualified , start to raise the temperature at 20°C / h, rise to 220°C, and keep the temperature constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com