Paper packaging machine

A paper bag and rack technology, applied in the field of paper bag machines, can solve the problems of low reliability of explosion-proof bottles, inconstant reasoning of the cardboard pushing device, and limited response speed of pneumatic parts of the pneumatic page arrangement device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

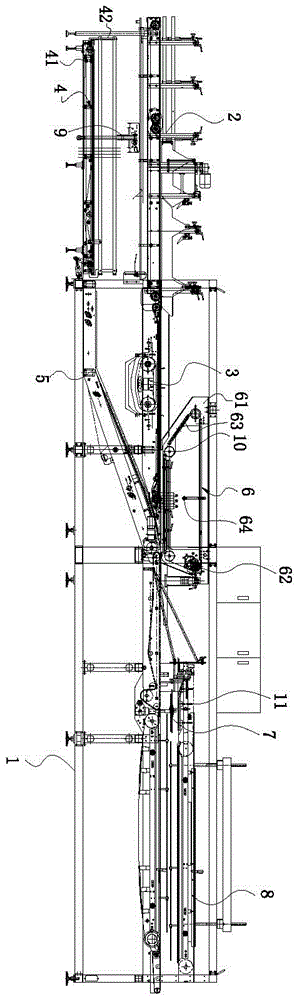

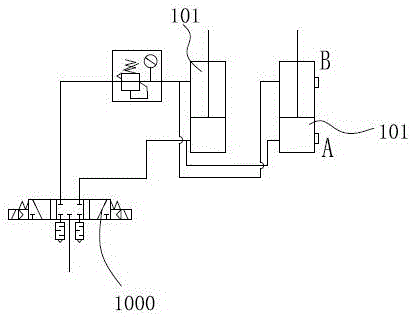

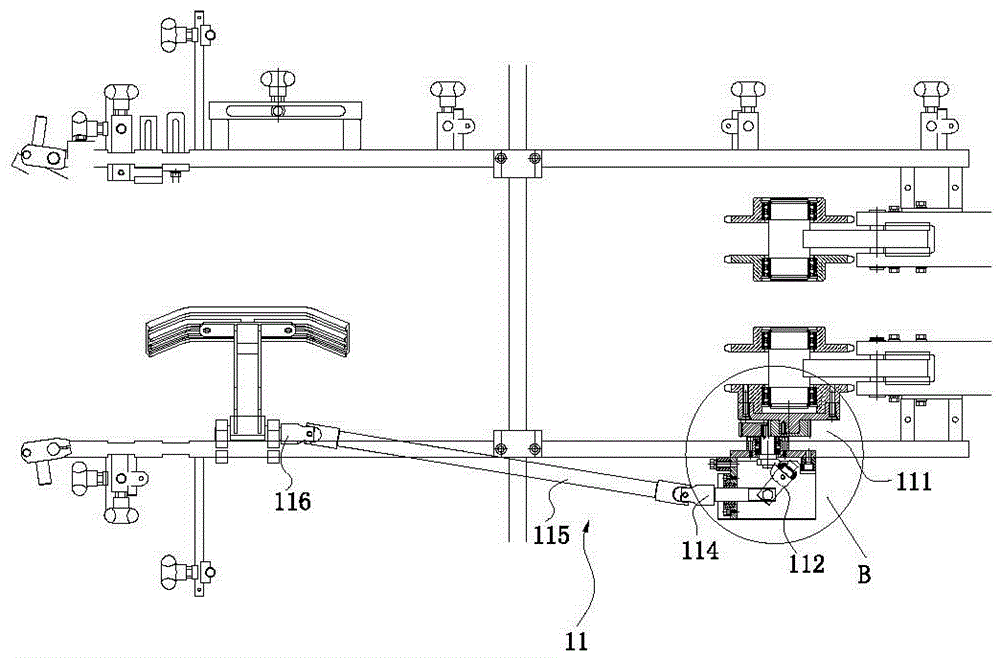

[0032] Such as figure 1 and figure 2 As shown, a paper wrapping machine includes a frame 1, on which a bottle feeding conveying device 2, a bottle separating device 3, a cardboard warehouse 4, a paper loading device 5, a bottle driving device 6, and a side folding device 7 are arranged. , Press box forming device 8, pneumatic constant pressure paper pushing device 9, bottle anti-jamming device 10 and mechanical clapping device 11.

[0033] The bottle feeding conveying device 2, the bottle separating device 3, the bottle driving device 6, the mechanical clapping device 11, the side folding device 7, and the pressing box forming device 8 are arranged in sequence according to the conveying direction. The cardboard bin 4 is located below the bottle feeding conveying device 2 , and the paper loading device 5 is at the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com