Conveying device of fully-automatic express carton packaging machine

A transmission device and packaging machine technology, applied in packaging and other fields, can solve the problem that automatic packaging machines are only suitable for single-size carton sealing, and achieve the effects of improving sealing efficiency, low manufacturing cost, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

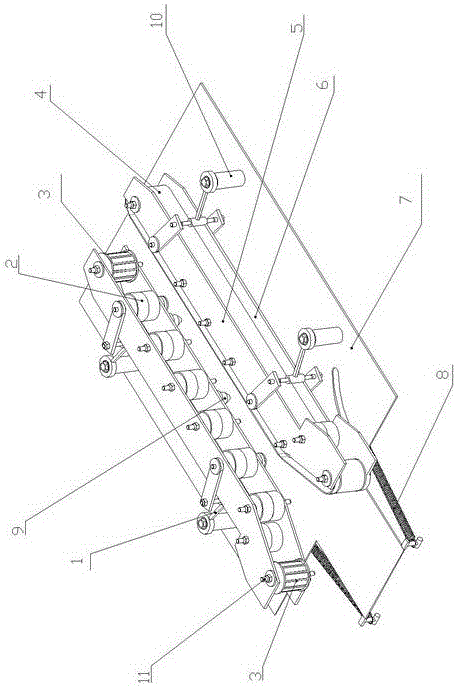

[0014] see figure 1 As shown, the present invention includes connecting frame rod 1, bearing 2, toothed belt wheel 3, toothed belt 4, upper splint 5, lower splint 6, bottom plate 7, spring 8, universal wheel 9, frame 10 and driving shaft 11 , the two toothed belts 4 are symmetrically arranged left and right; the upper splint 5 and the lower splint 6 are connected by studs, a plurality of bearings 2 are installed on the studs, and the bearings 2 act as rollers to support the toothed belt 4; The toothed pulley 3 is fixedly connected to the driving shaft 11; each shaft is fixed between the upper splint 5 and the lower splint 6 through two bearings 2, and the two toothed pulleys 3 are distributed between the upper splint 5 and the lower splint 6. end; the motor is connected to the drive shaft 11 through a coupling, and the motor drives the drive shaft 11 to rotate, thereby driving the toothed belt 4 to run; the two connecting rods 1 at the front and rear fix the upper splint 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com