Arresting net lifting device

A lifting device and arresting net technology, applied in the direction of the stop device, etc., can solve the problems of easy scratching, wire rope damage, large friction resistance, etc., and achieve the effect of good protection, reduced friction resistance, and strong mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

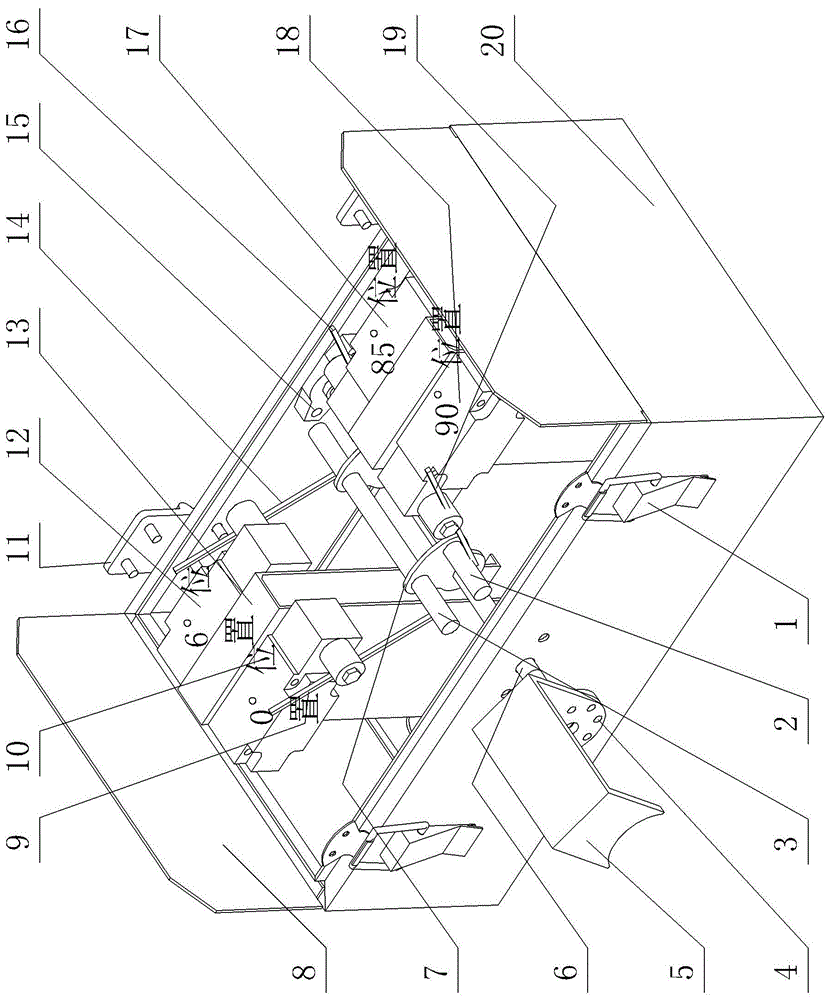

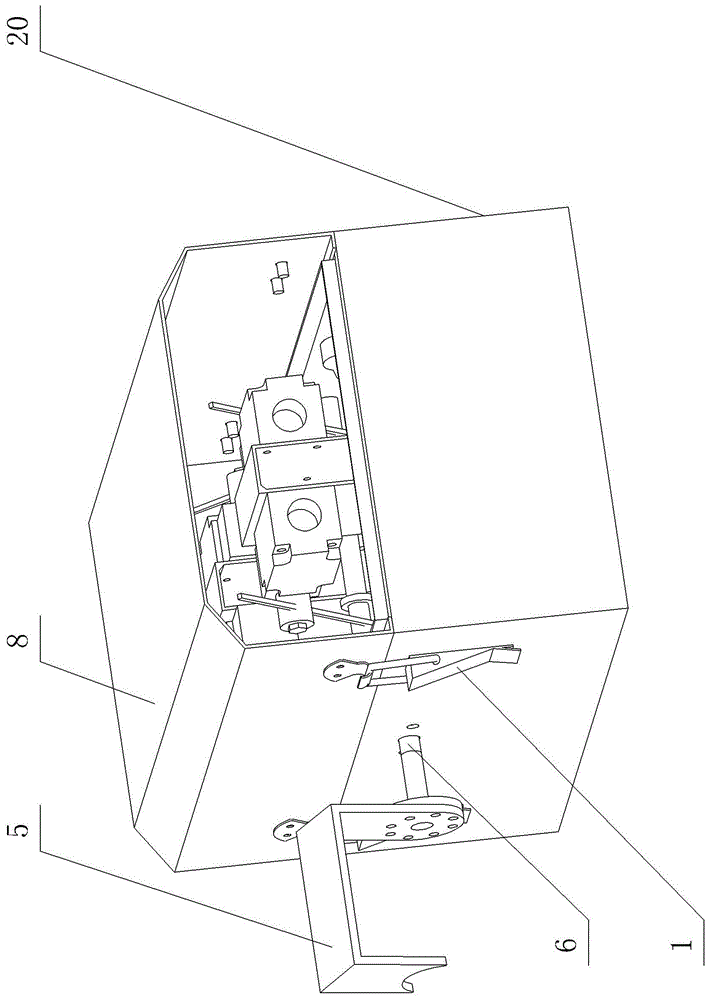

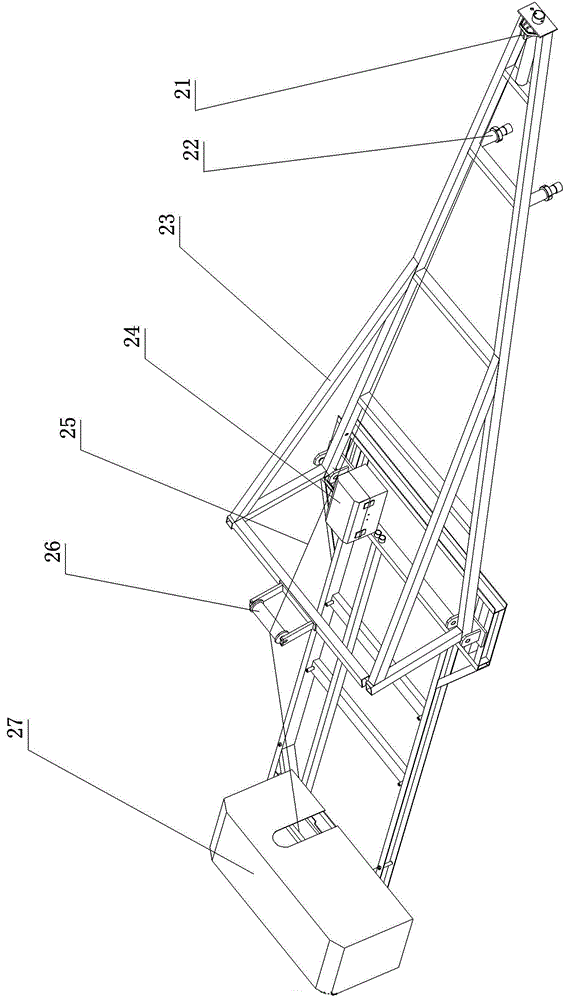

[0022] As shown in the figure, the present invention includes a grid frame, a lifting grid motor and a grid base, the rear end of the grid frame is connected to the front end of the grid base through a rotating shaft, and the lifting grid motor is arranged at the rear end of the grid base. There are upward support rods on both sides of the rear end of the grid, cross beams are provided between the support rods on both sides, a mounting seat is provided in the middle of the beam, vertical support plates are provided on both sides of the mounting seat, and nylon is provided between the upper ends of the support plates. ground roller.

[0023] The rotating shaft of the lifting net frame motor is connected to one end of the steel wire rope, and the other end of the steel wire rope is connected to the front end of the net frame by bypassing the upper end of the nylon ground roller.

[0024] The upper end of the support rod is provided with a groove, and a horizontal installation ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com