Limp control method and system based on electric car distributed drive system

A motor drive system, a technology for electric vehicles, applied in electric vehicles, control drives, control devices, etc., can solve problems such as the inability to realize the limp function, and achieve the effect of reducing road rescue, ensuring operation stability, and reducing road occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A limp control method based on electric vehicle distributed drive system, is characterized in that, comprises the following steps:

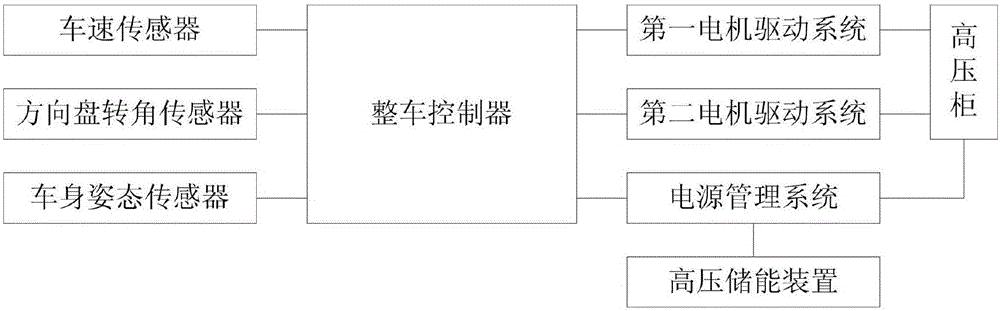

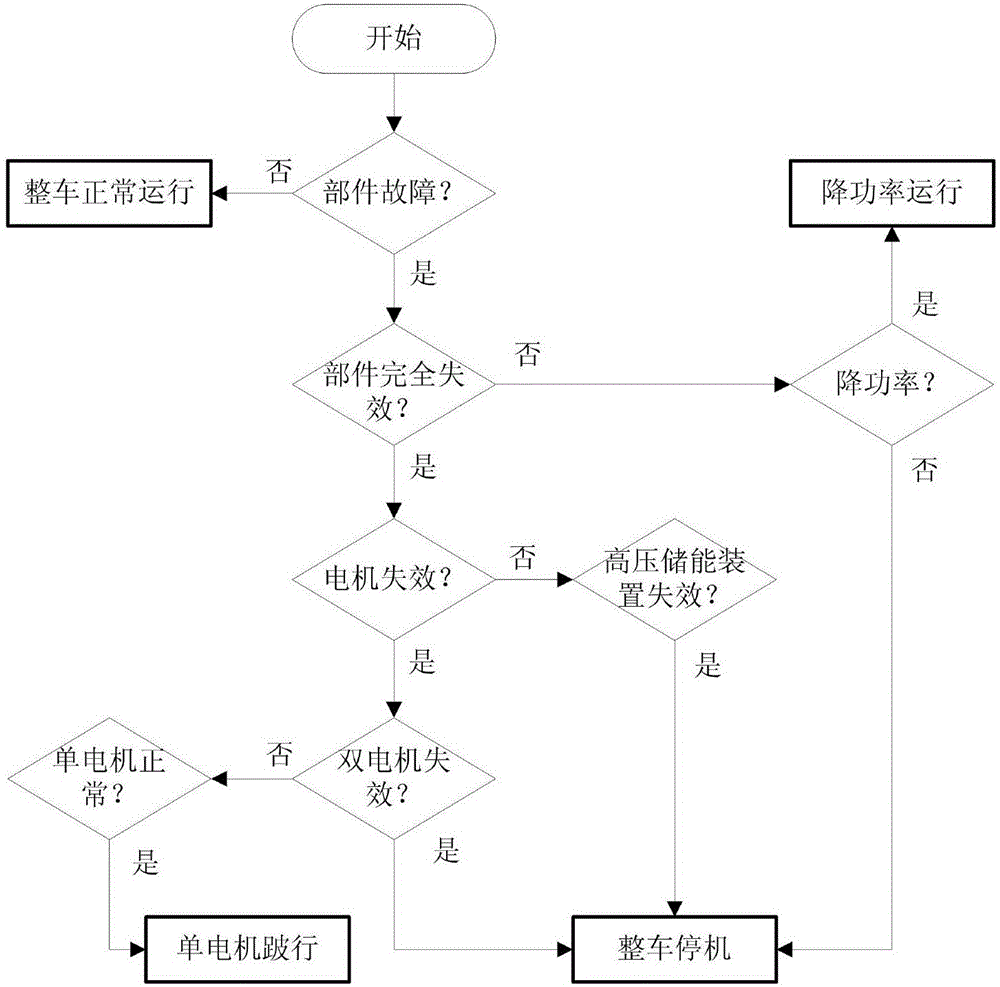

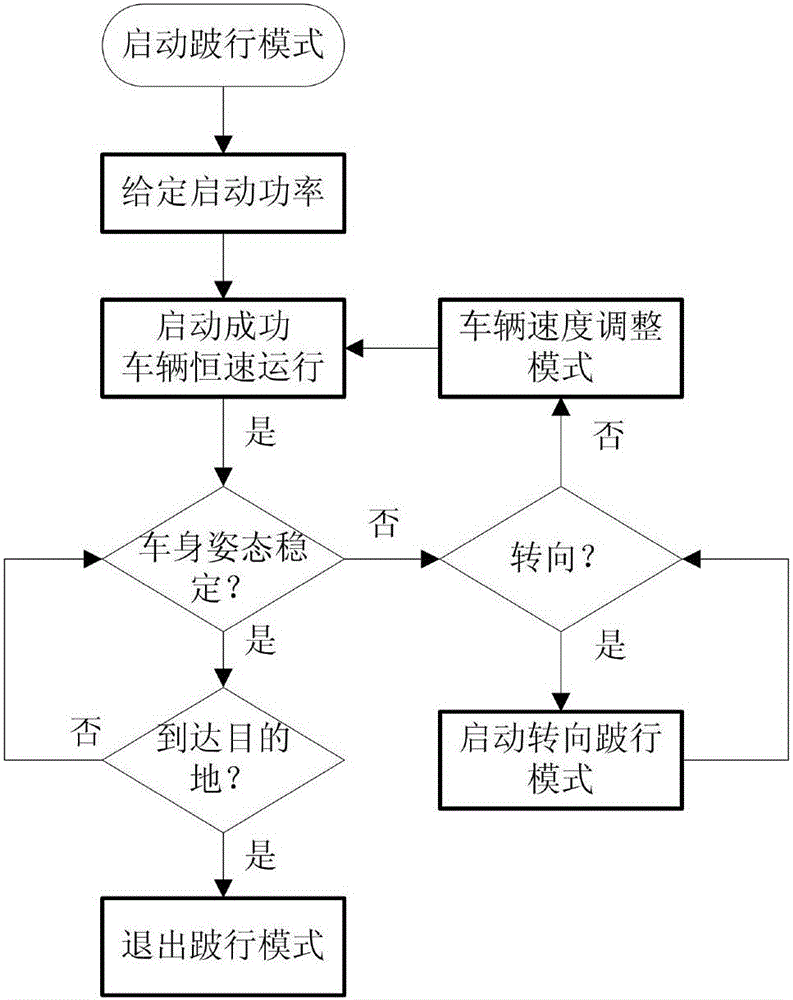

[0031] Step (1): If figure 2 As shown, during the operation of the electric vehicle, the vehicle controller judges in real time whether there is a fault in the motor drive system according to the operating state of the electric vehicle, and when a fault occurs, the vehicle controller classifies the severity level according to the fault type, and the serious The severity level is divided into: power reduction operation, single motor limp and vehicle stop; the fault types are divided into component failure, component complete failure, motor failure, high-voltage energy storage device failure, double motor failure and single motor normal; vehicle control The controller first judges whether the motor drive system is a component failure. If it is not a component failure, the whole vehicle will run normally. If it is a component failure, it wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com