A snow tire groove with a bionic non-smooth pattern

A snow tire, non-smooth technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of rough structure, no shape feature ratio, no improvement of tire heat dissipation performance and service life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

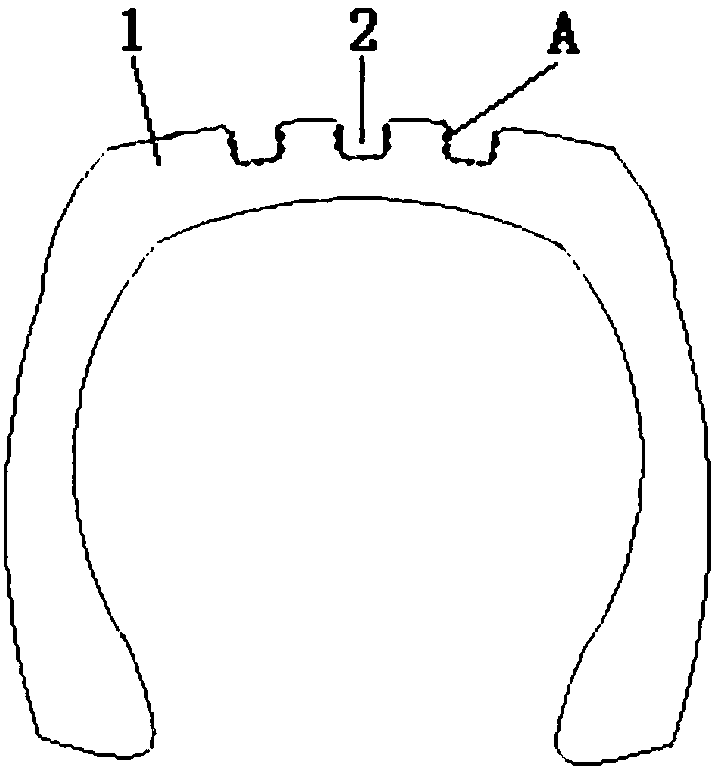

[0028] Such as figure 1 As shown, the cross section of the groove 2 is U-shaped, the depth is 6-16mm, the bottom width is 5-12mm, the angle between the side wall of the groove 2 and the longitudinal axis of the vertical tread is 0-5°, the groove 2 The side wall and the bottom of the groove are arc-shaped.

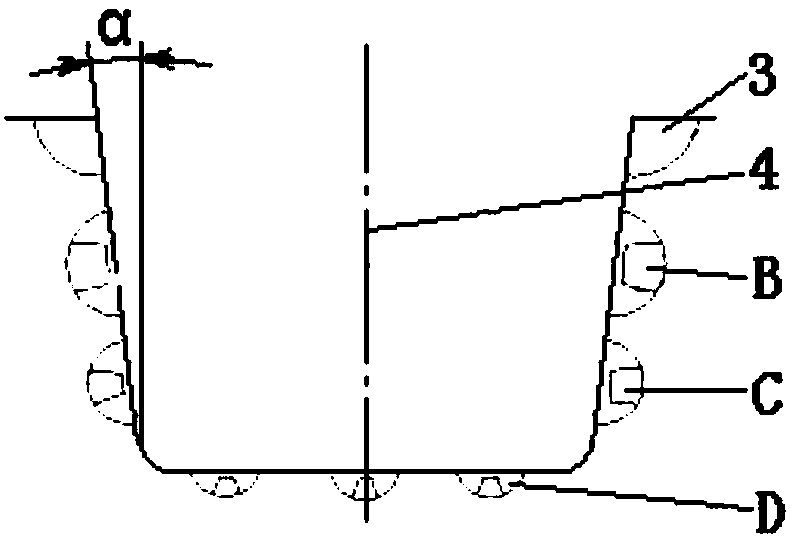

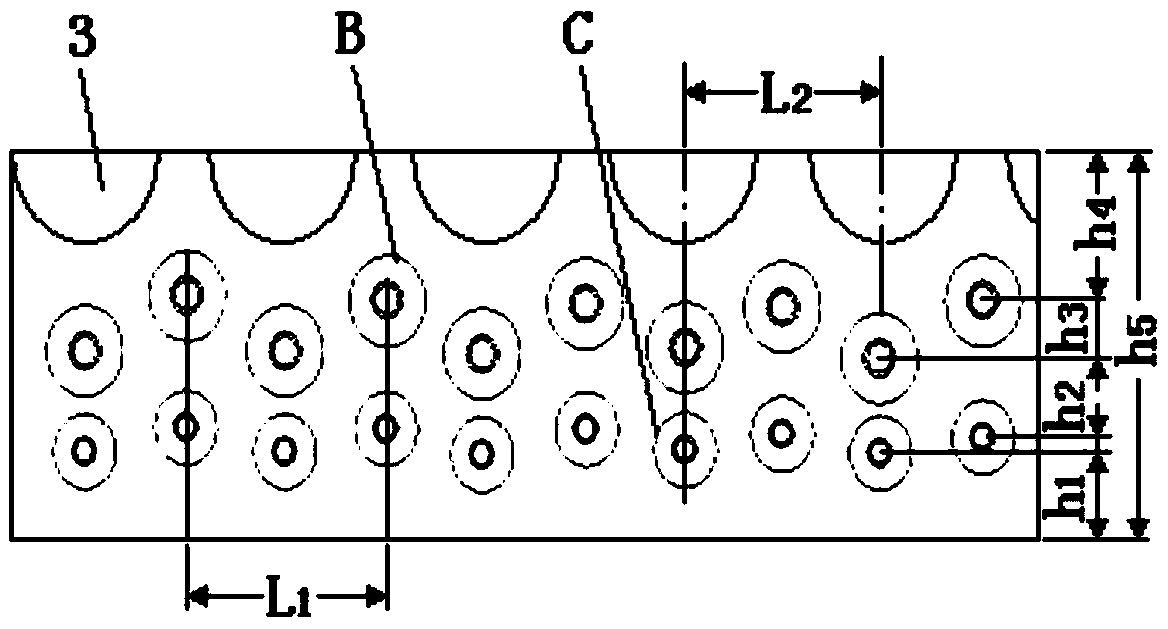

[0029] Such as figure 2 , 5 As shown, the bionic non-smooth pattern A is composed of a hemispherical pit 3, a concave-convex structure IB, a concave-convex structure IIC, and a concave-convex structure IIID. The radius of the hemispherical pit 3 is r 1 1.5-4mm; the bionic non-smooth pattern A on both sides of the groove 2 is distributed symmetrically with respect to the longitudinal axis I4.

[0030] Such as image 3 As shown, the hemispherical pit 3 of the bionic non-smooth pattern A on one side of the groove 2, the concave-convex stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com