Novel foam forming machine and foam forming method

A molding machine and foam technology, which is applied in the field of foam molding machine and its foam molding, can solve the problems of large investment in molds, non-universal molds, time-consuming and laborious mold replacement, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

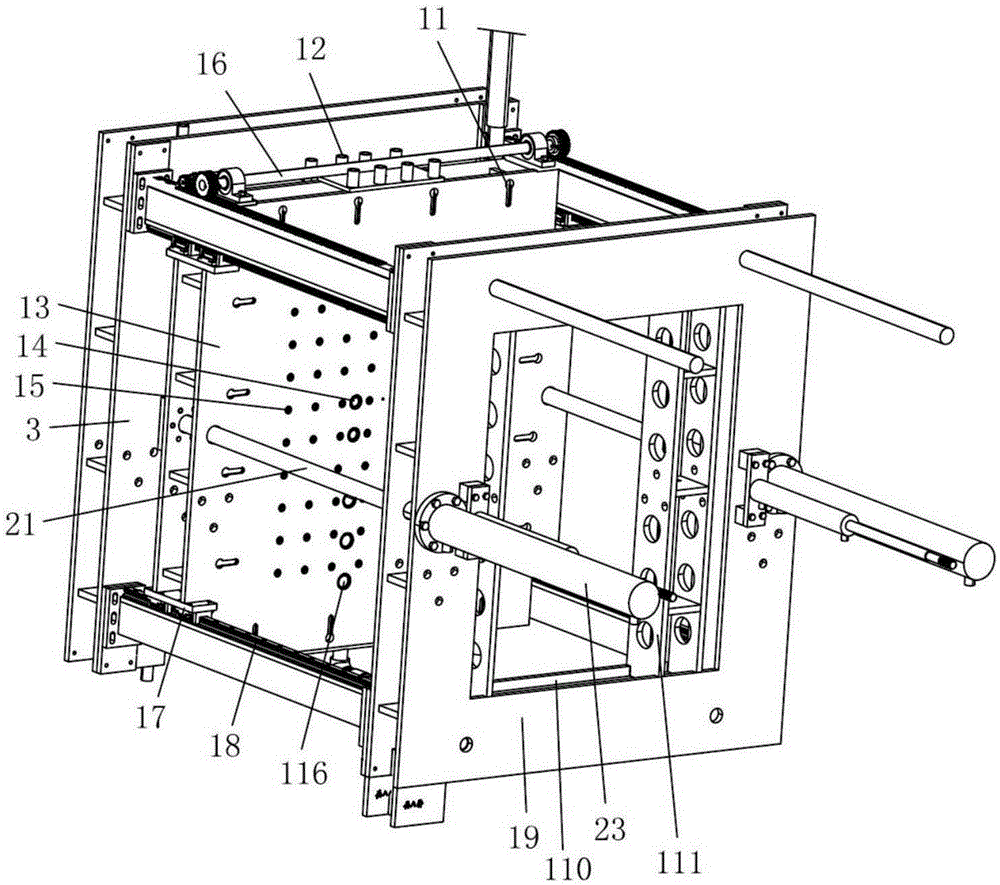

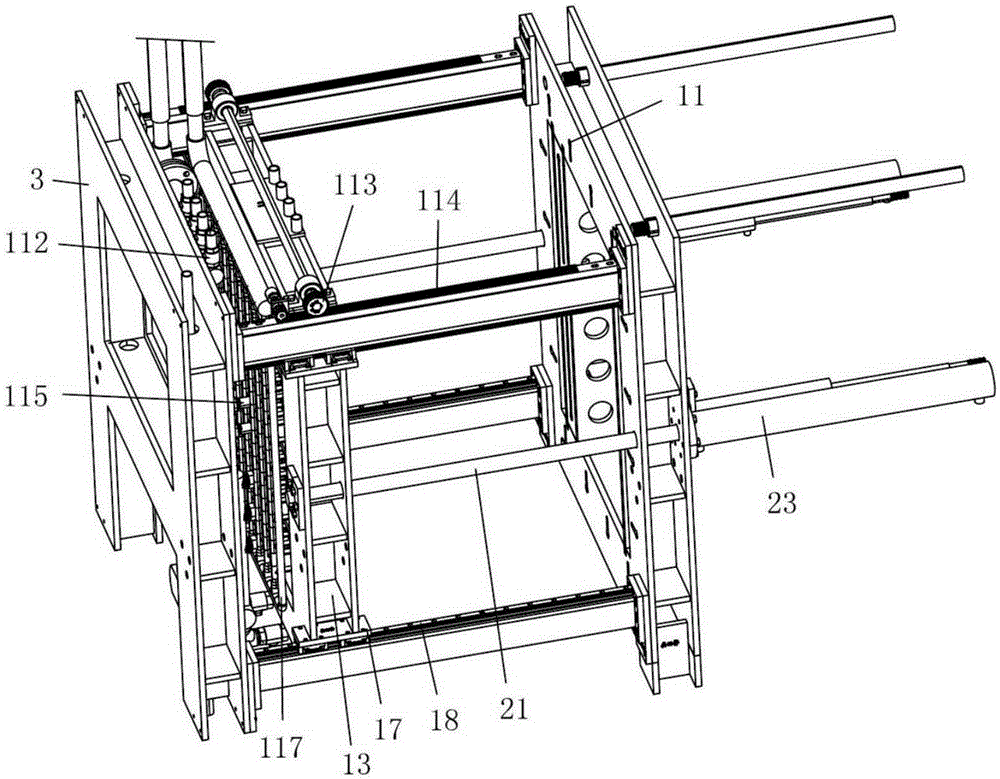

[0055] Such as Figure 1-7 As shown, a new type of foam forming machine includes a frame 3, and the frame 3 is provided with a feeding system 1, a mold installation mechanism, a steam heating system, a cooling water system, a demoulding mechanism and an electrical automation control system 5 .

[0056] The mold installation mechanism includes a solid template 7 and a movable template 13, the fixed template and the movable template are used to fix the mould, the movable template 13 and the solid template 7 are arranged on the same horizontal line, and the fixed template is fixedly installed on the frame In the middle part, the moving template 13 is movably connected on the frame 3, and the moving template 13 is driven to move left and right on the frame 3 by an oil cylinder to form an opening and closing structure with the solid template 7, and the oil cylinder is In tension mode, the oil cylinder includes a cylinder body 23, a piston, a piston rod 21 and an end cover. templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com