Hazardous chemical solution extraction system based on mobile robot

A mobile robot and solution extraction technology, applied in the direction of sampling, instruments, manipulators, etc., can solve problems such as being vulnerable to injury, not being able to move freely, suspension of hazardous solution processing, etc., to reduce labor intensity and safety risks, and facilitate automation and Effect of standardization and improvement of environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

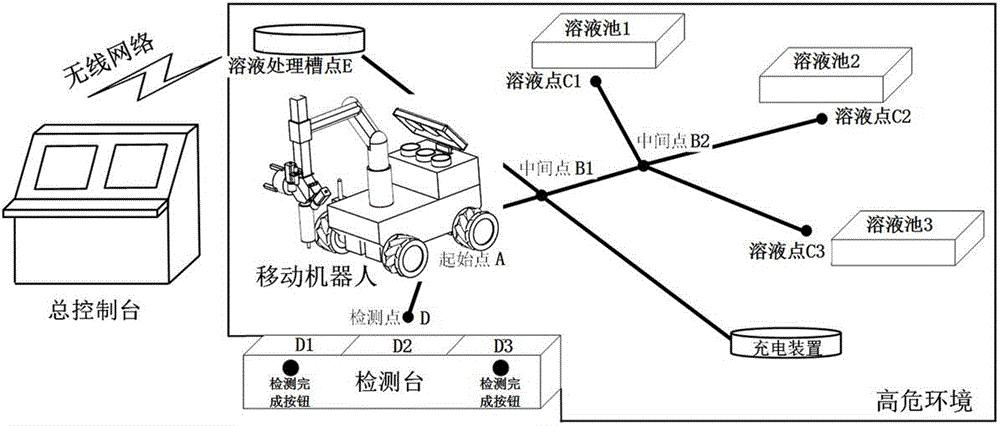

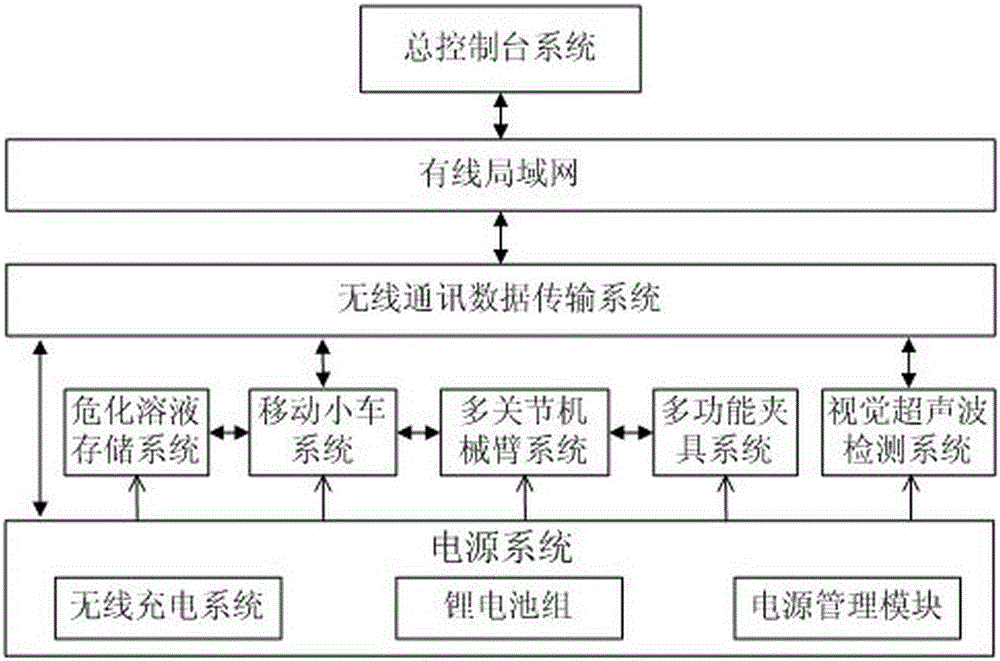

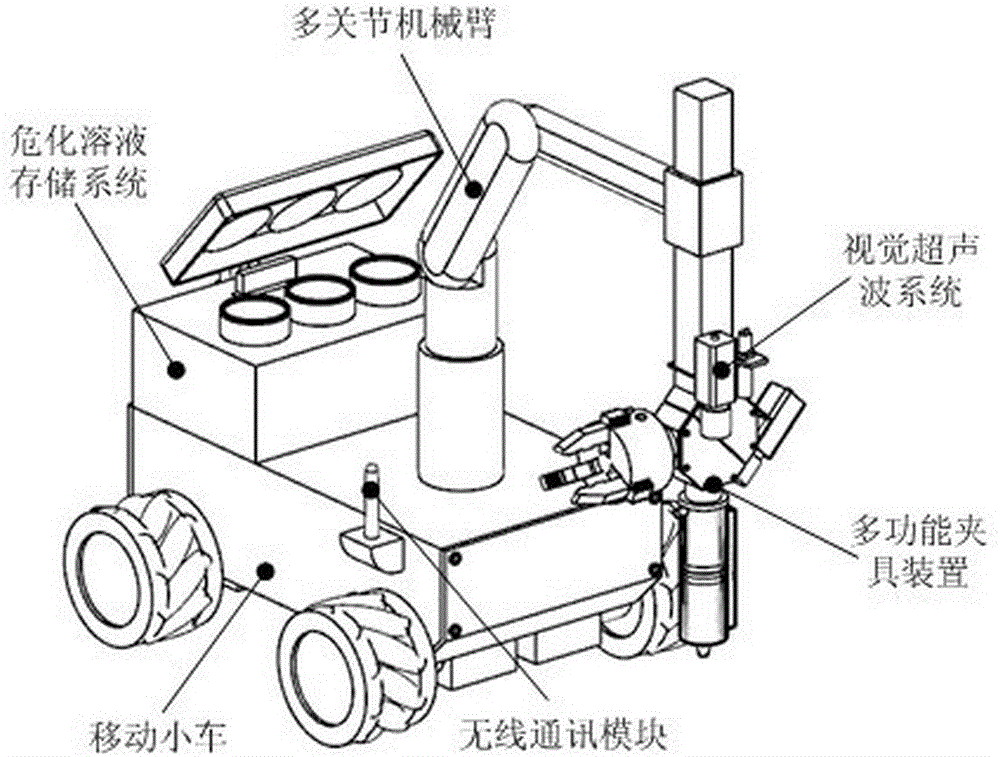

[0040] According to the characteristics of high radioactivity and high corrosiveness of hazardous chemical solutions and the process of automatic quantitative extraction, considering the operational safety and reliable realization of functions, an automatic quantitative extraction system for hazardous chemical solutions based on mobile robots is designed. The working principle is as follows: figure 1 shown. The idea of separating the control mechanism and the executive mechanism is adopted as a whole. The mobile robot system is placed inside the high-risk environment as the actuator, and the main console is placed outside the high-risk environment as the control mechanism. It has good flexibility in the scene where the chemical composition is uncertain, there are many types, and the random quantitative extraction of hazardous chemical solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com