Shaped wrench

A wrench and special-shaped technology, applied in the field of wrenches, can solve problems such as inconvenient use, affecting work progress, and loose bite, etc., and achieve the effect of large contact area, easy operation, and stable torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

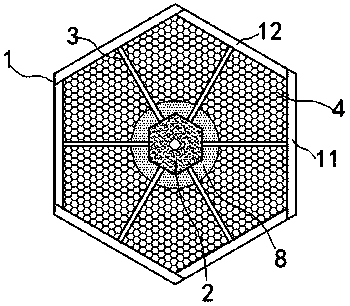

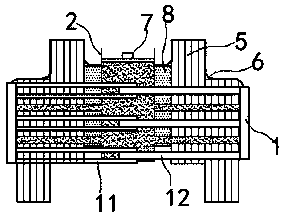

[0019] exist figure 1 , figure 2 In the shown embodiment, the special-shaped wrench includes a fixed frame 1 and an adjustment column 2;

[0020] The fixed frame 1 includes a splint 11 and a slide bar 12, the fixed frame 1 is arranged in a staggered manner connected end to end by the splint 11 and the slide bar 12, and forms a closed ring; the top view of the fixed frame 1 is a regular hexagon Shape; anti-slip stoppers are provided at the ends of the splint 11 and the slide bar 12; the stoppers are not shown in the figure;

[0021] The adjustment column 2 is a cylindrical structure with a closed bottom; the adjustment column 2 is arranged on the axis of the fixed frame 1, and an elastic telescopic tube 3 is arranged on the outer peripheral wall of the adjustment column 2 symmetrically, and the elastic telescopic tube 3 One end is fixed and airtightly connected to the splint 11 or the slide bar 12, and the other end is connected to the adjustment column 2; the elastic telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com