Polishing head with dustproof function and polishing machine

A grinding head, dust-proof technology, applied in grinding/polishing equipment, grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, etc. Bearing and grinding head damage and other problems, to achieve the effect of improving polishing accuracy, unique structure and good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

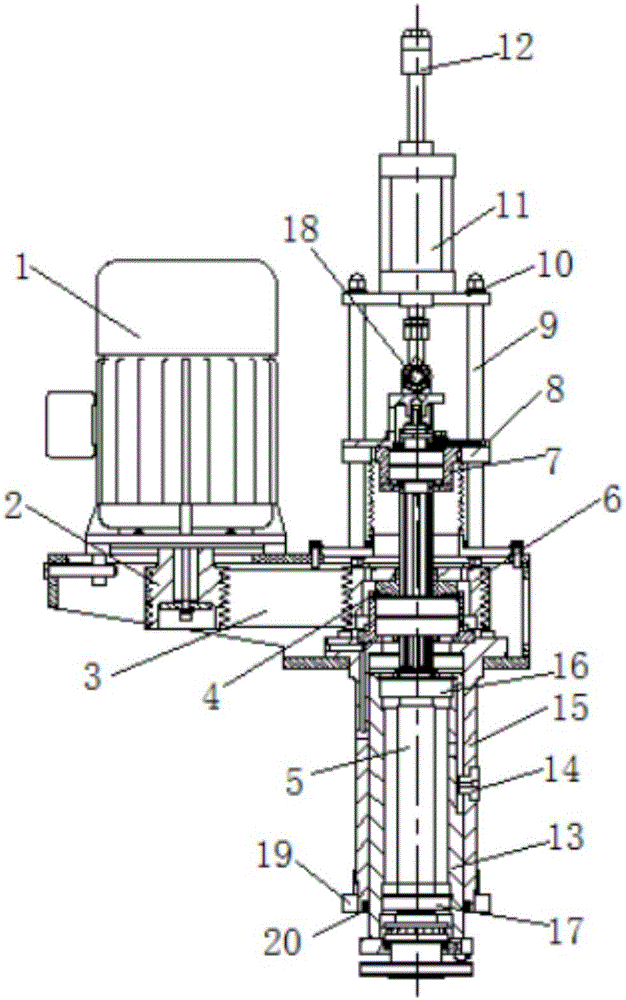

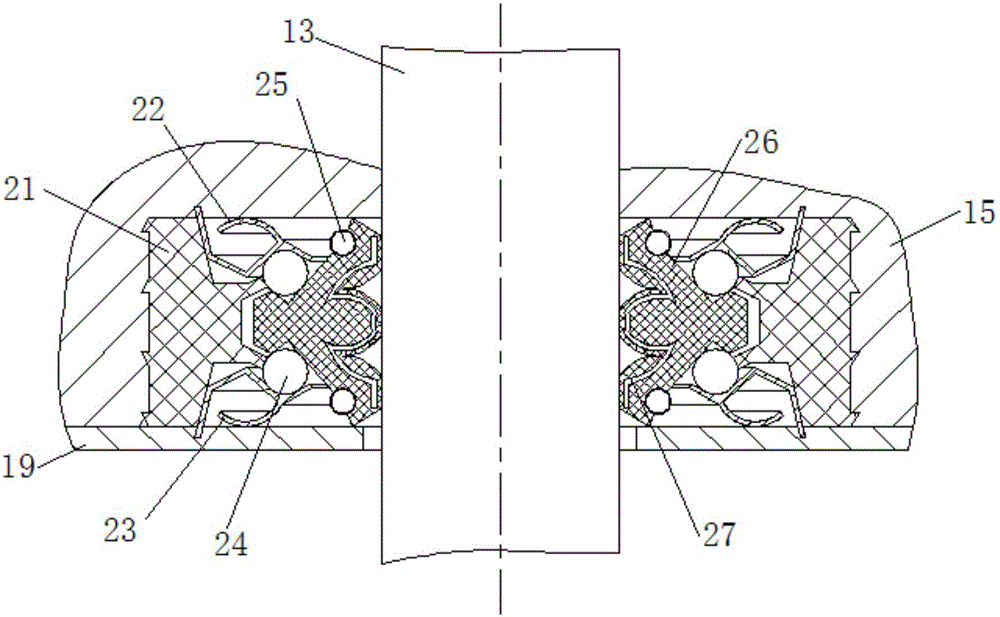

[0036] refer to Figure 1 to Figure 10 ,like figure 1 The shown a kind of grinding head with dust-proof, comprises headstock 15 and sealing device 20, and described headstock 15 is provided with the sliding sleeve 13 that can move up and down; In the sealing cavity 151, it is sleeved on the sliding sleeve 13, and resists on the end cover 19 of the headstock 15, as figure 2 As shown, the sealing device 20 includes a body 21 , an upper elastic body 22 , a lower elastic body 23 , a sealing portion 26 and a pair of annular bodies 24 .

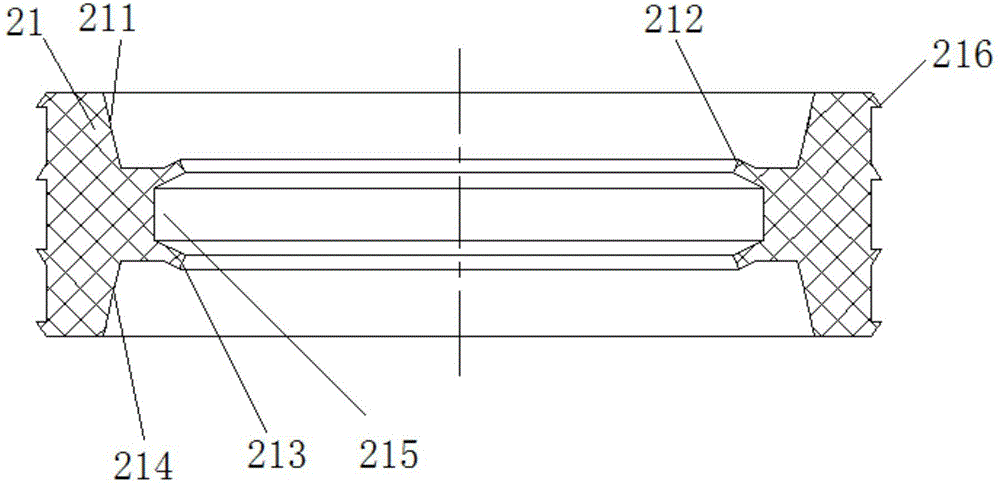

[0037] like figure 2 , image 3 and Figure 7As shown, the body 21 is fixedly connected to the tooth groove 152 on the inner wall of the sealing chamber 151 through the tines 216 on the outer periphery, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com