Sawing machine clamp of improved structure

A technology of jigs and sawing machines, which is applied in the direction of clamping, manufacturing tools, supports, etc., which can solve the problems of low cutting efficiency and achieve the effects of improving work efficiency, safe and reliable pressing, and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

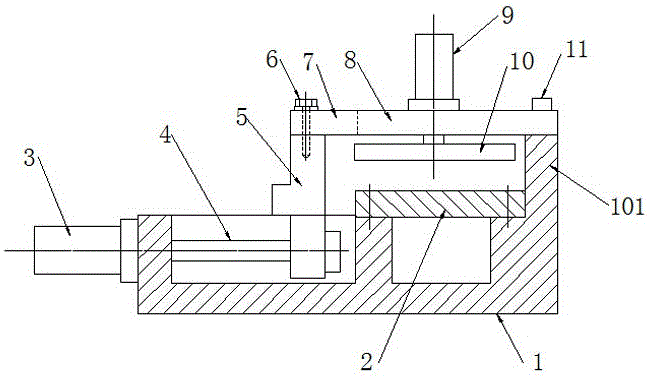

[0010] Such as figure 1 As shown, the sawing fixture with an improved structure includes a fixture body 1 and a movable clamping plate 5. The fixture body 1 is a vise-type body structure. One end of the fixture body is a fixed clamping plate 101. The middle part of the fixture body 1 is provided with a mounting groove. , the movable clamping platen 5 is guided on the fixture body, and the cylinder 3 is installed on the fixture body, and the piston rod of the cylinder 3 is fixedly connected with the bottom of the movable clamping platen 5; A supporting plate 2 fixed on the fixture body is provided between the pressing plates 101;

[0011] A connecting plate 8 is arranged on the fixed clamping platen 101 and the movable clamping platen 5, and one end of the connecting plate 8 is fixedly connected to the fixed clamping platen 101 by a screw 11, and the other end of the connecting plate is provided with a U-shaped slot 7 , the screw and gasket assembly 6 pass through the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com