Automatic assembling system of overflow valve

A technology for automatic assembly and overflow valve, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure, unsatisfactory processing effect, and complicated process setting of the automatic assembly system of overflow valve, and achieves practicability. High, high cost, avoid the effect of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

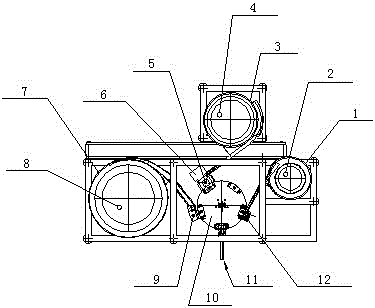

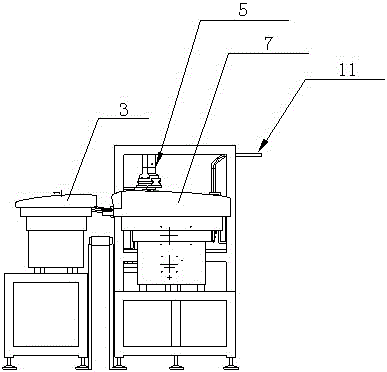

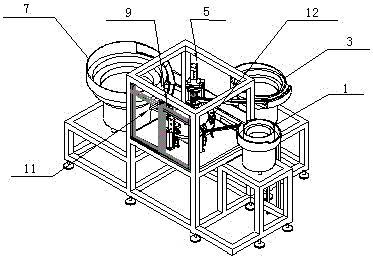

[0030] see figure 1

[0031] figure 1 It is a top view of the present invention. exist figure 1 Among them, the overflow valve automatic assembly system includes three shock plates 1, 3, and 7 that are connected to the driving device and surround the divider 10. The shock plate one 1 is connected to the push slider group one 12 through transmission, and the shock plate two 3 is in transmission connection with the rotary chuck group 5, and the shock plate three 7 is in transmission connection with the pushing slider group two 9, and the central shaft of the divider 10 is provided with a spring tube 11.

[0032] The push slider group one 12 is in transmission connection with the divider 10 .

[0033] The push slider group two 9 is in transmission connection with the divider 10 .

[0034] The shock plate one 1 for placing the accessory one 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com