Tooling for assembly and welding of roulette body and method of use

A roulette body assembly and welding technology, which is applied in the field of heat treatment, can solve the problems of stress concentration, cracks, and increased scrap rate of the roulette body, and achieve the effect of solving deformation and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

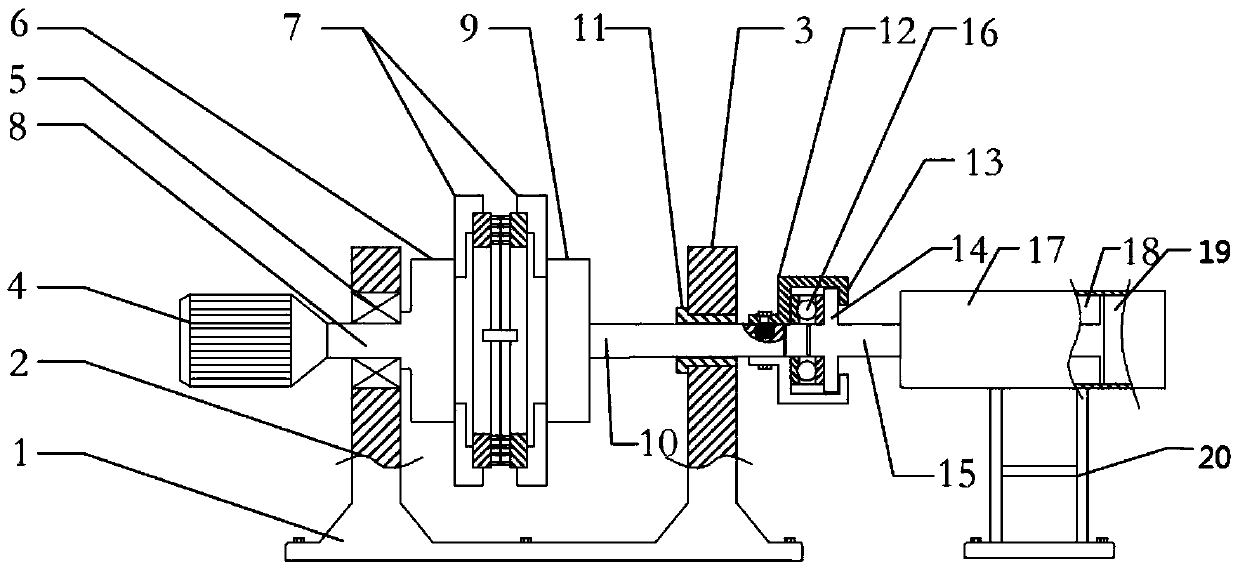

[0041] Such as figure 1 As shown, a tooling for assembly and welding of a roulette body includes a support seat 1, a left support column 2, a right support column 3, a stepping motor 4, a rolling bearing 5, an active chuck 6, a short shaft 8, a long claw 7, Also includes passive chuck 9, long shaft 10, bearing sleeve 11, return shaft sleeve 12, return pull plate 13, push pull plate 14, push shaft 15, thrust bearing 16, cylinder 17, return air chamber 18, working air chamber 19 , Cylinder support 20.

[0042] Wherein the support seat 1 is fixed with a left support column 2 and a right support column 3, and the left support column 2 and the right support column 3 are relatively arranged and are all perpendicular to the support seat 1. The rolling bearing 5 is installed on the left support column 2, the rolling shaft 5 and the left support c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com