Nano silver prepared through low-temperature reducing of reducing sugar, preparing method of nano silver and application of nano silver to conductive ink

A conductive ink and nano-silver technology, applied in the application, ink, nanotechnology and other directions, can solve the problems of glucose carbonization deformation, easy gelatinization, difficult to use as a reducing agent of nano-silver, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

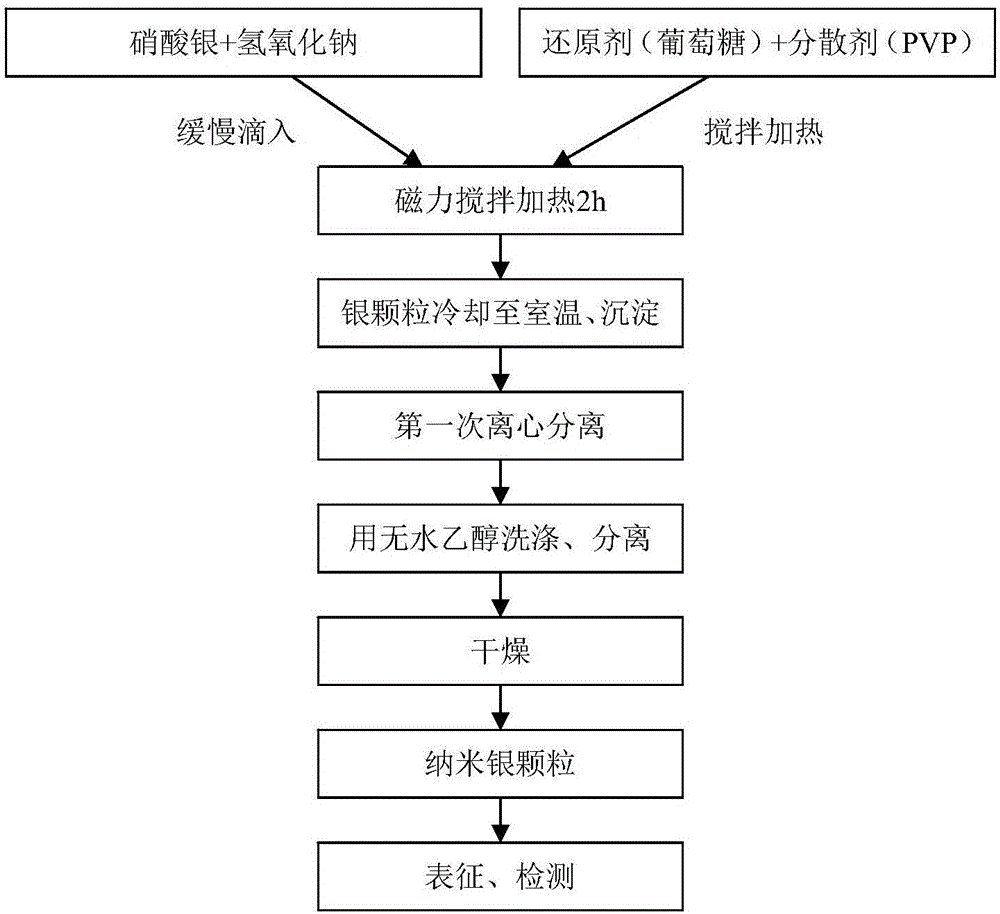

Method used

Image

Examples

Embodiment 1

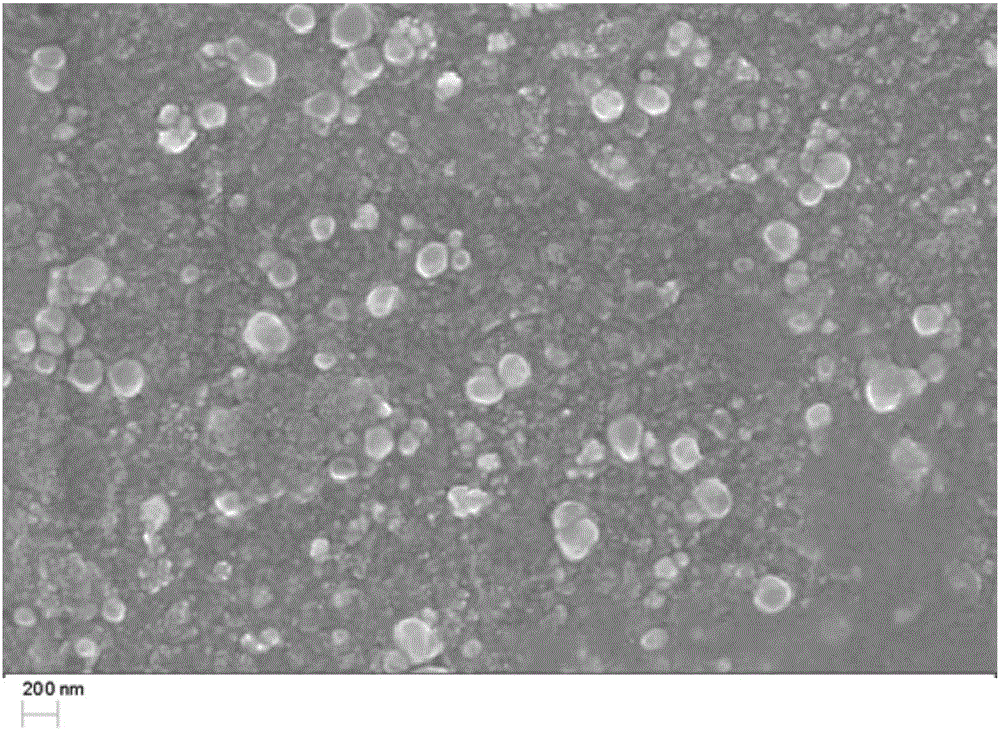

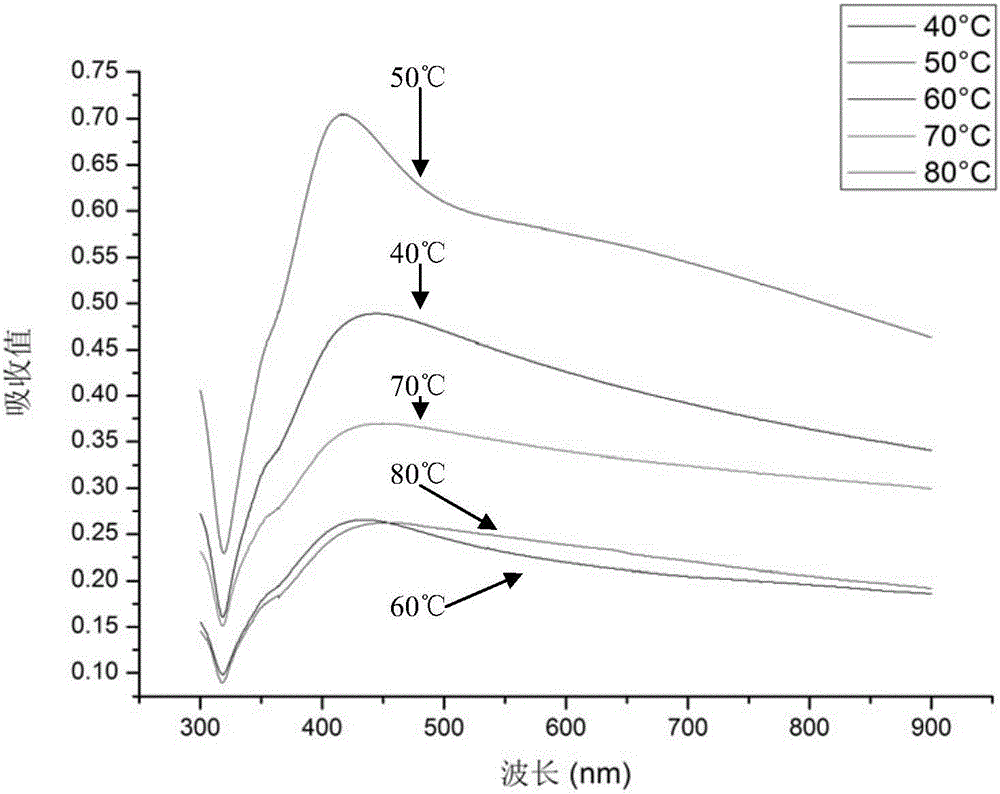

[0034] (1) Add 50ml of deionized water to 0.7206g of anhydrous glucose and polyvinylpyrrolidone (PVP) (mass ratio: 2:1.5), put it on a constant temperature magnetic stirrer, heat it in a water bath at 50°C at 1500r / Min speed stirring 60min dubbed Solution A. Add 3 mol / L sodium hydroxide solution to silver nitrate (the molar ratio of silver nitrate and PVP is 1:1.5), adjust the pH to 11, and make dark brown suspension B. Add the suspension B into the solution A, stir at 50°C and 1500r / min, and the solution turns gray after 120 minutes of reaction to end the reaction. After the solution was cooled to room temperature, the solution was added to a centrifuge tube and centrifuged at a speed of 10000 r / min for 10 min. After centrifugation, pour out the supernatant, add absolute ethanol to the centrifuge tube, perform ultrasonic vibration to disperse, and then perform 10min centrifugation at a speed of 10000r / min for 3 times. Put the washed nano-silver in a small weighing bottle a...

Embodiment 2

[0039] (1) Add 50ml of deionized water to 0.4579g of anhydrous glucose and polyvinylpyrrolidone (PVP) (mass ratio: 2:1.5), put it on a constant temperature magnetic stirrer, heat it in a water bath at 60°C at 1500r / Min speed stirring 60min dubbed Solution A. Add 2 mol / L sodium hydroxide solution to silver nitrate (the molar ratio of silver nitrate and PVP is 1:1.5), adjust the pH to 11, and make dark brown suspension B. Add suspension B into solution A, stir at 60°C and 1500r / min, and the solution turns gray after 120 minutes of reaction to end the reaction. After the solution was cooled to room temperature, the solution was added to a centrifuge tube and centrifuged at a speed of 10000 r / min for 10 min. After centrifugation, the supernatant was poured out, absolute ethanol was added into the centrifuge tube, and ultrasonic vibration was performed to disperse, and then centrifuged at a speed of 10000r / min for 10min for 4 times. Put the washed nano-silver in a small weighing...

Embodiment 3

[0044] (1) Add 50ml of deionized water to 0.5666g of anhydrous glucose and polyvinylpyrrolidone (PVP) (ratio: 2:1) and put it on a constant temperature magnetic stirrer. Min speed stirring 80min dubbed Solution A. Add 2 mol / L sodium hydroxide solution to silver nitrate (the molar ratio of silver nitrate and PVP is 1:1), adjust the pH to 12, and make dark brown suspension B. Add the suspension B into the solution A, stir at 80°C and 2000r / min, and the solution turns gray after 150 minutes of reaction to end the reaction. After the solution was cooled to room temperature, the solution was added to a centrifuge tube and centrifuged at a speed of 12000 r / min for 12 min. After centrifugation, pour out the supernatant, add absolute ethanol into the centrifuge tube, perform ultrasonic vibration to disperse, and then perform 12min centrifugal cleaning at a speed of 12000r / min for 5 times. Put the washed nano-silver in a small weighing bottle and put it in an oven for drying. The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com