Automatic casting powder feeding device and method of articulated robot

An automatic slag adding and robot technology, applied in the field of steelmaking and continuous casting, can solve problems such as crushing, dust pollution, waste, etc., and achieve the effect of maintaining the original shape, solving large volume, and smooth slag adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

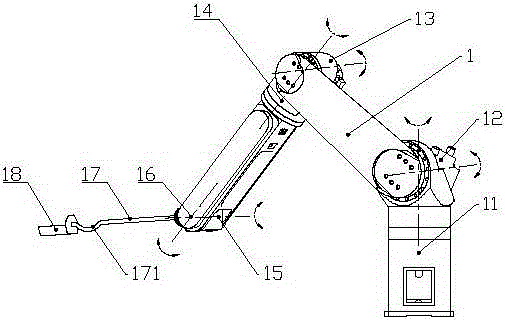

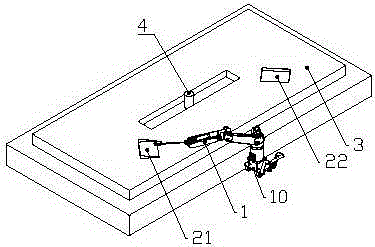

[0037] Embodiment 1, a joint robot automatic slag adding device is used for automatic slag adding of a first-class large-section crystallizer, such as Figure 2-Figure 3 As shown, the joint manipulator 1 is installed on the mobile trolley 10. When not working, the mobile trolley and the joint manipulator 1 on it can be evacuated to a storage place away from the crystallizer; 1. Place it on the casting platform facing the center of nozzle 4 and close to the mold cover for automatic slag addition. Optionally, a translation mechanism of the lead screw and nut pair can also be installed on the mobile trolley, and the joint robot is installed on the translation mechanism. When working, the joint robot moves in a direction parallel to the width of the crystallizer driven by the translation mechanism.

[0038]It should be noted that the moving trolley 10 is not limited to a trolley that is manually driven to move, and may be driven by an electric motor or the like to move. The slag ...

Embodiment 2

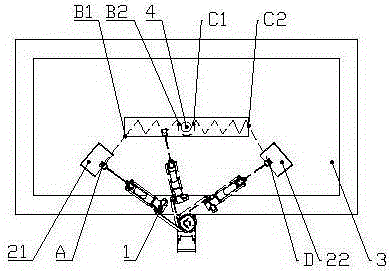

[0039] Embodiment 2, a joint robot automatic slag adding device is used for the automatic slag adding of crystallizers 31, 32 with small and medium sections (such as billets, rectangular billets, and round billets), such as Figure 4-5 Shown, it is the application of the automatic slag adding device of the two-stream rectangular billet crystallizer. The difference between this embodiment and the first embodiment lies in the moving path of the slag adding spoon 18 and the timing of pouring mold slag during the moving process. In this embodiment, the set path means that the slag adding spoon 18 goes from point A (left slag basin 21) → point B1 (upper left part of the mouth of crystallizer 31) → point B2 (upper right part of mouth of crystallizer 31) → D Point (right slag basin 22)→C1 point (upper right part of crystallizer 32 mouth)→C2 point (left upper part of crystallizer 32 mouth)→A point, so reciprocating. Among them, between point A and B1, between point B2 and point D, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com