Energy-saving casting system reasonably utilizing casting area space

A regional and spatial technology, applied in the field of energy-saving casting systems, can solve the problems of unstable casting quality, high labor intensity of workers, and many processes, so as to reduce the power consumption of mains electricity, avoid safety liability accidents, and improve operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

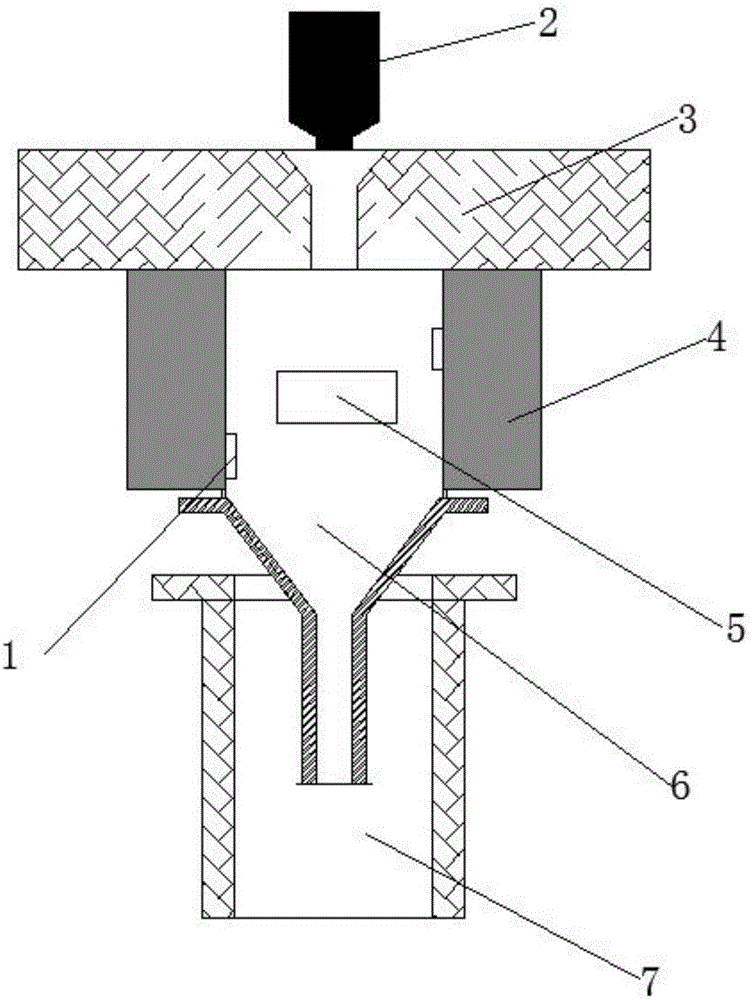

[0071] An energy-saving casting system that rationally utilizes the space of the casting area, effectively utilizes the space position in the area where the casting system is located, uses the roof of the area where the casting system is located as the erection ground for photovoltaic panels, and uses solar power generation mode for power supply, so as to maximize Reduce the electricity consumption of mains electricity, and further have the purpose of saving energy. The whole system has the characteristics of scientific setting, convenient and safe use, and high production efficiency, such as figure 1 , figure 2 As shown, the following configuration structure is particularly adopted: a casting system and a control system for casting system control are provided, a power supply system and a control circuit are arranged in the control system, and the power supply system is connected to the control circuit and the casting system respectively. connection, the control circuit is co...

Embodiment 2

[0074] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, it can facilitate the comparison of real-time data and prefabricated data, thereby effectively adjusting the heating temperature of the heating device, thereby ensuring the quality of the casting. Such as figure 1 , figure 2 As shown, the following arrangement structure is adopted in particular: an analog-to-digital conversion circuit, a central processing unit, a digital-to-analog conversion circuit, a display circuit and an adjustment circuit are arranged in the control circuit, and the temperature detector 1 is connected to the analog-to-digital conversion circuit, The analog-to-digital conversion circuit is connected to the central processing unit, the DC circuit is connected to the central processing unit, the central processing unit is respectively connected to the display circuit and the analog-to-digital conversion circuit, the...

Embodiment 3

[0076] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. In order to better realize the present invention, PLC technology is used for temperature adjustment and power supply control, so as to avoid the entire casting system from being slowed down due to system errors in the control circuit itself. , so as to further avoid safety liability accidents, such as figure 1 , figure 2 As shown, the following arrangement structure is particularly adopted: a PLC control circuit, a temperature adjustment switch, an AC contactor and a heater control switch are arranged in the regulating circuit, the digital-to-analog conversion circuit is connected to the PLC control circuit, and the PLC control circuit is respectively It is connected with the temperature adjustment switch and the AC contactor, the AC contactor is connected with the heater control switch, the heater control switch is connected with the AC circuit, and the heater control switch i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com