A device for rolling ribs on a cover

A technology of rolling ribs and lids, which is applied in the field of lid rolling ring edge devices, can solve the problems of high equipment manufacturing costs, not very ideal, and large floor space of mechanical equipment, and achieve good forming effects, convenient disassembly and replacement, and improved The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

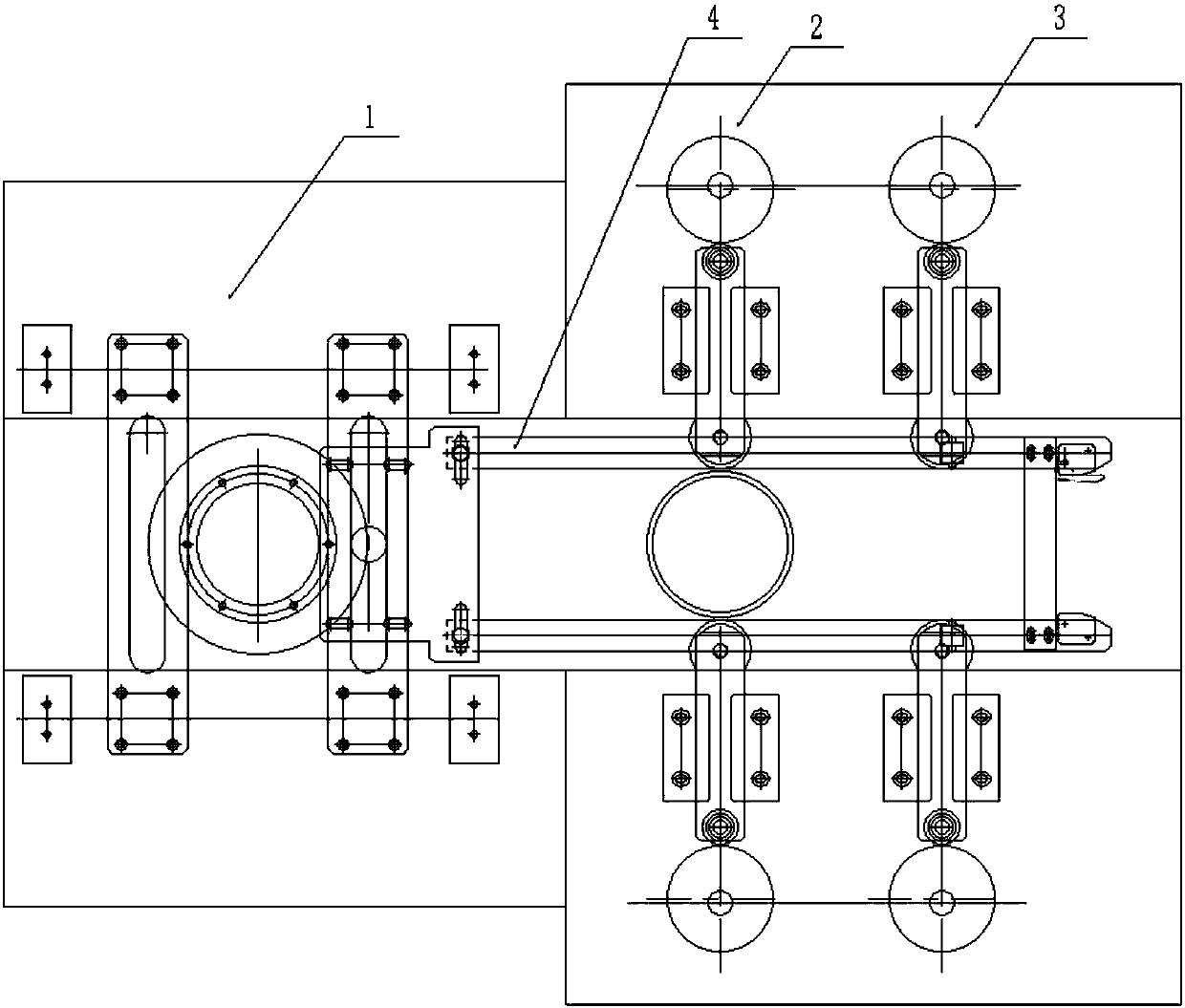

[0028] As shown in the figure, a lid rolling device according to an embodiment of the present invention includes:

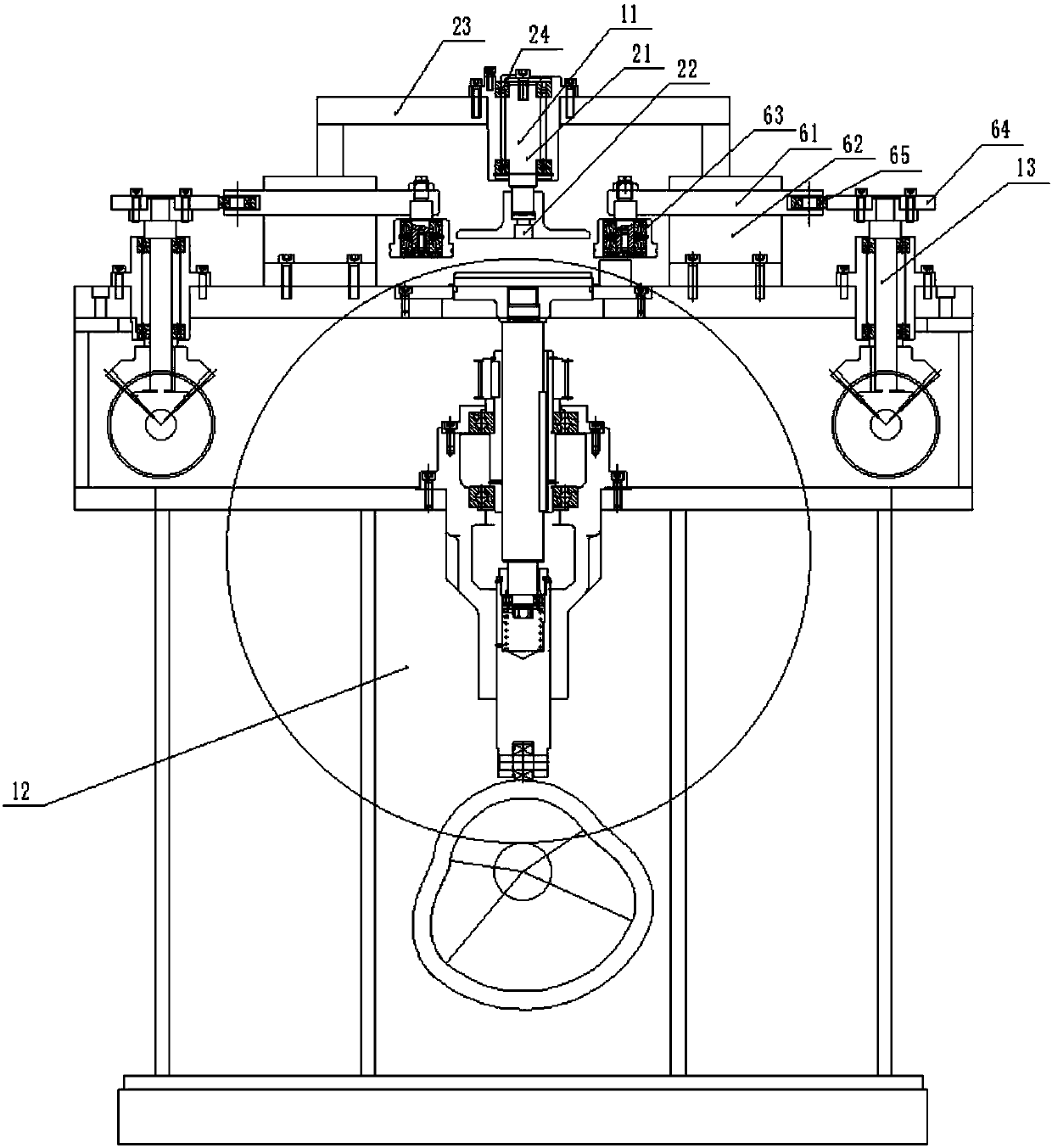

[0029] like figure 1 As shown, the bead rolling mechanism 2 includes an upper capping mechanism 11, a lower rotary jacking mechanism 12 and a left-right symmetrical knife feeding mechanism 13;

[0030] like figure 2 As shown, the capping mechanism 11 includes a rotating shaft 21, the rotating shaft 21 is fixed on the jacking frame 23 through the rolling bearing 124, the jacking frame 23 is fixedly connected with the frame, and the pressing head 22 is connected below the rotating shaft 21;

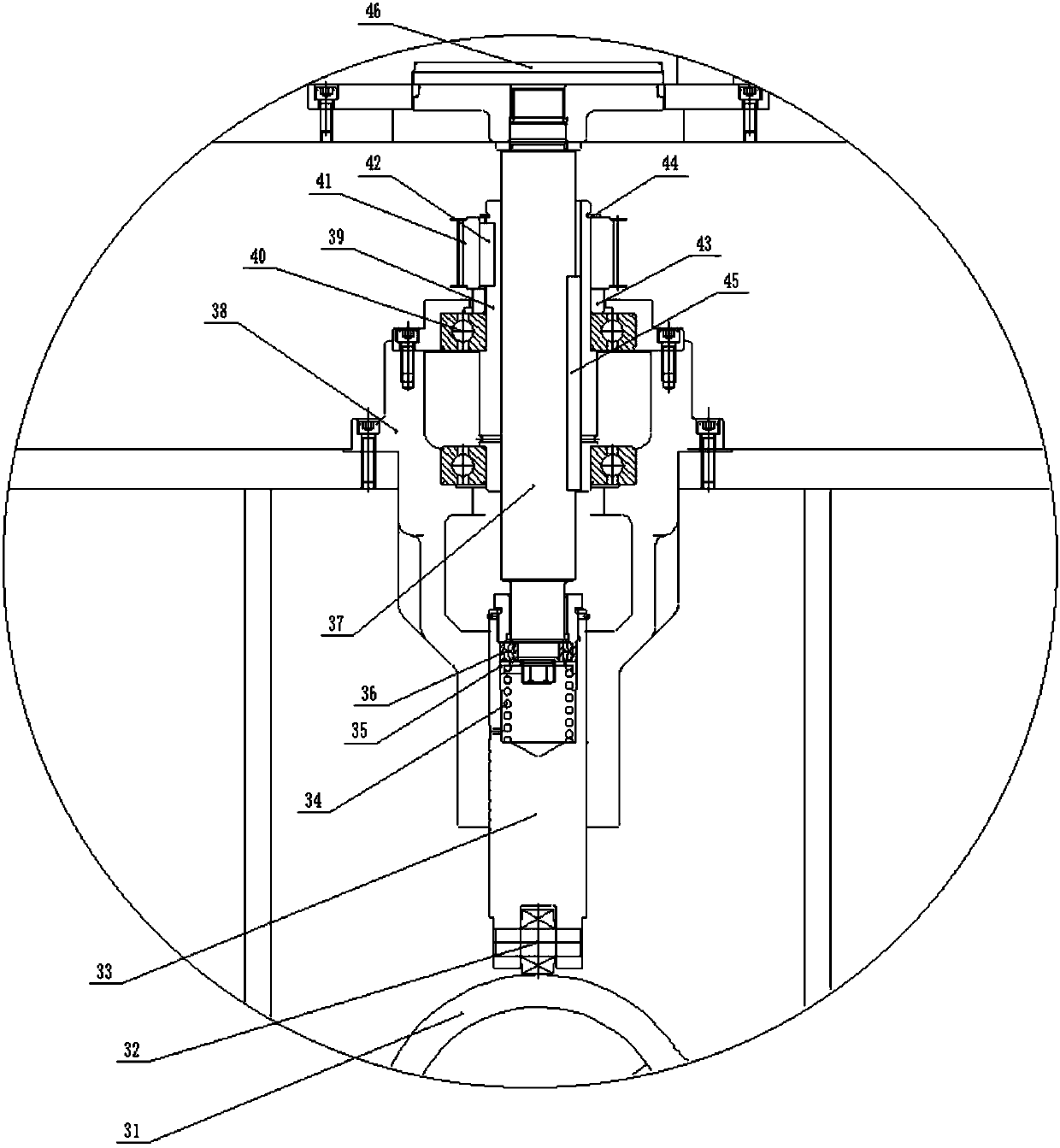

[0031] like image 3 As shown, the rotary jacking mechanism 12 includes a power cam 31, the top of the power cam 31 is connected to the connecting shaft 33 through the rolling bearing II32, the connecting shaft 33 is installed under the outer shaft sleeve 38 through clearance fit, and the outer shaft sleeve 38 is fixedly connected with the frame. The upper part of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com