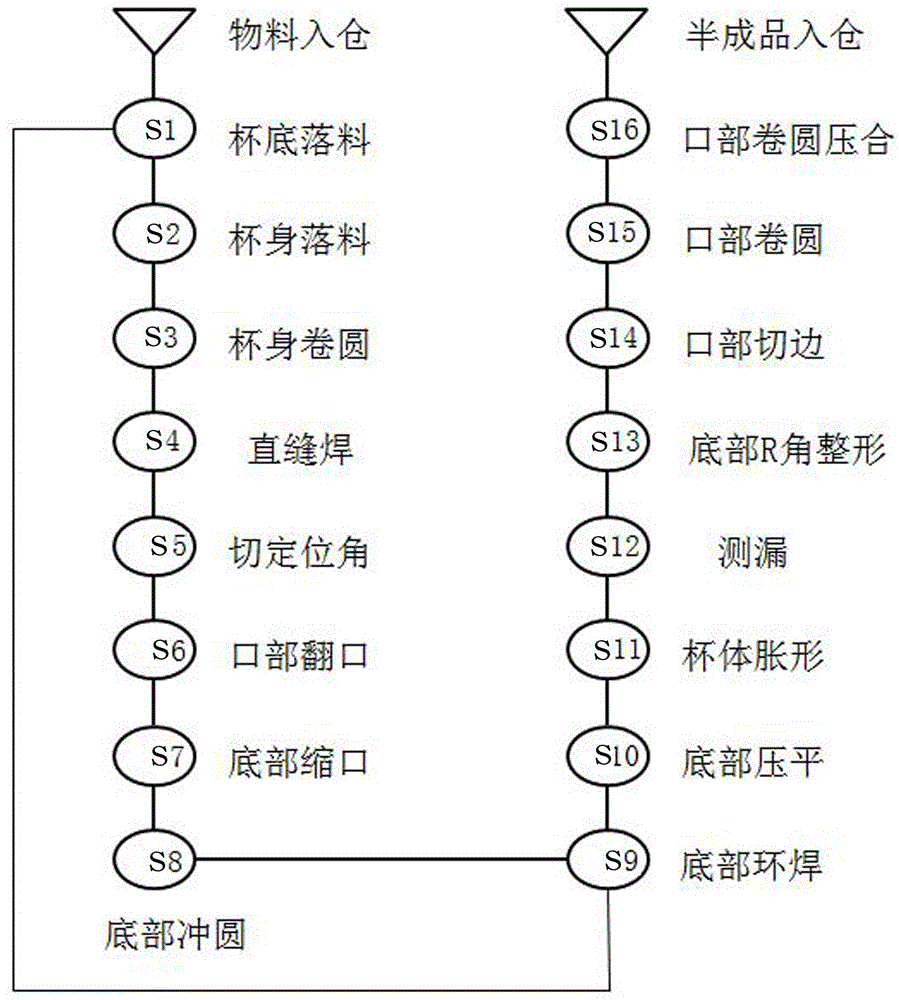

Cup body processing method

A processing method and a cup body technology, which can be applied to other household appliances, household appliances, applications, etc., and can solve the problems of easy damage, low production efficiency, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] For the cup body processing method, according to the present invention, its improvements are mainly reflected in the two levels of mouth processing and bottom processing. The special equipment used will be explained below.

[0053]The first is bottom shaping: For containers that need bottom shaping, it is more common to see such as the inner pot of the rice cooker, the ordinary deep pot, etc., the bottom of which needs to have a certain R angle. On the one hand, it is easy to clean, and on the other hand On the one hand, this kind of products are generally produced by deep drawing process, which belongs to cold processing process. When deep drawing is deep, it often cannot be formed at one time, and it needs multiple deep drawing to form, otherwise it is easy to crack.

[0054] The deep drawing and stretching here belong to different processes, the deep drawing belongs to the forming process, and the drawing belongs to the processing process after the forming process. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com