Punch die fast replacing device

A stamping die and fast technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of plastic deformation, time-consuming and labor-intensive, and reduced precision of sheet metal parts, so as to reduce rebound performance, improve precision, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

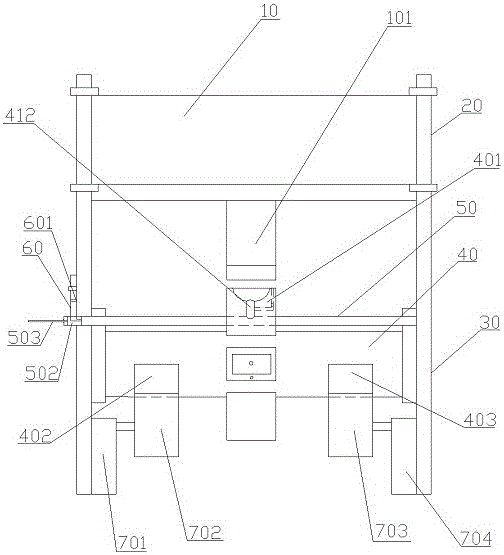

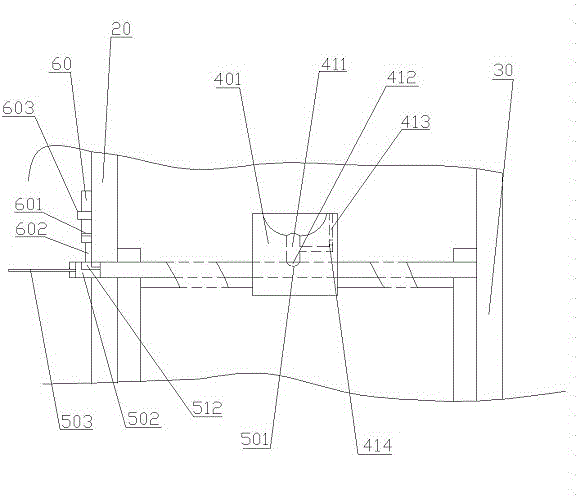

[0022] The reference signs in the drawings of the description include: hydraulic table 10, upper mold 101, frame 20, machine table 30, rotating shaft 40, lower mold 401, first through hole 411, first seal 412, return hole 413, electromagnetic Valve 414, first transmission tooth 402, second transmission tooth 403, limit rod 50, second through hole 501, slider 502, third through hole 512, slider 503, second seal 504, alcohol tube 60, A liquid level sensor 601 , a water pipe 602 , a fixed frame 603 , a first motor 701 , a first driving gear 702 , a second motor 703 , and a second driving gear 704 .

[0023] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a stamping die quick replacement device, including a hydraulic table 10 and a frame 20 . The hydraulic platform 10 is arranged on the upper end of the frame 20, and the hydraulic platform 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com