Method for rolling pure titanium strip by using Sendzimir 20-high mill

A 20-roll rolling, pure titanium technology, applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of thickness, surface shape can not be effectively guaranteed, less usage, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Brand: TA1, width 1240mm, raw material thickness 4.0mm, finished product thickness 1.0mm.

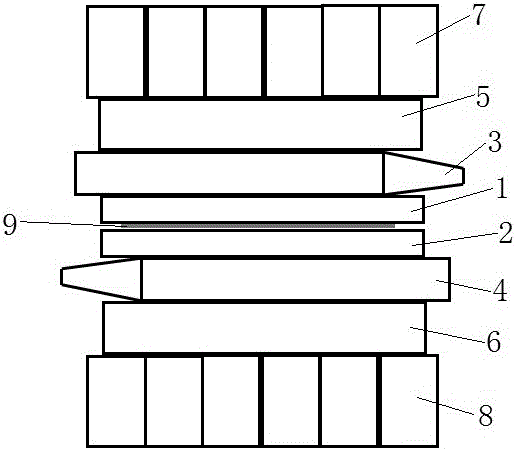

[0030] ⑴Roll system configuration

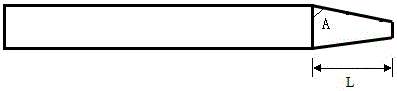

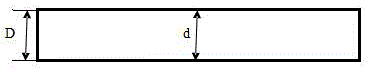

[0031] The convexity of the two intermediate free rolls is 0.20mm at the top and bottom, the cone length of the first intermediate roll is 280mm, and the taper is 0.26%, and the working rolls use flat rolls.

[0032] ⑵Correction coefficient of thickness gauge

[0033]

[0034] ⑶ surface control

[0035] ①The rolling speed is controlled at 130m / min;

[0036] ② The pass deformation rate is controlled between 8.5-21%;

[0037] ③The flow rate of rolling oil for strip cooling is 7800L / min;

[0038] ④ The strip inlet and outlet flow ratio should be controlled at 0.6;

[0039] ⑤ The surface temperature of the strip steel is between 60-90°C.

[0040] Effect: The rolling of the pure titanium strip is successfully completed and the quality requirements required by the user are met. The thickness accuracy can be controlled within ±0.01mm, the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com