Glass bottle detecting device

A detection device and glass bottle technology, which is applied in sorting and other directions, can solve the problems of low detection efficiency, high detection cost, and high device manufacturing cost, and achieve the effects of reducing broken rate, improving detection efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

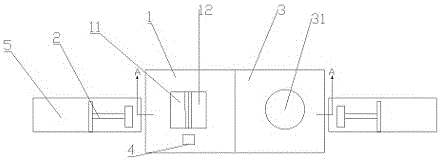

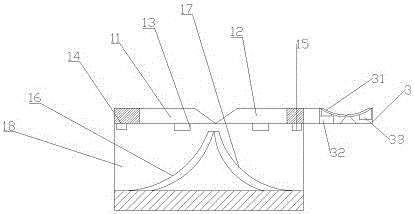

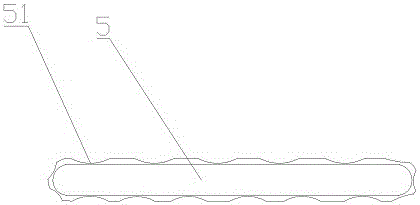

[0022] The reference signs in the accompanying drawings of the description include: workbench 1, first opening and closing plate 11, second opening and closing plate 12, magnet 13, first electromagnet 14, second electromagnet 15, first arc-shaped slide plate 16, second Arc-shaped slide plate 17, cavity 18, cylinder 2, carrying platform 3, turntable 31, first magnet protrusion 32, second magnet protrusion 33, detection camera 4, conveyor belt 5, arc groove 51.

[0023] Such as figure 1 , figure 2 , image 3 As shown, the glass bottle detection device includes a workbench 1, a cavity 18 is provided on the workbench 1, a first opening and closing plate 11 and a second opening and closing plate 12 communicating with the cavity 18 are hinged on the workbench 1, and the first opening and closing plate 12 communicates with the cavity 18. The right end of plywood 11 contacts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com