Array logistics automatic sorting equipment and working method thereof

A technology of automatic sorting and working methods, which is applied in the fields of dispatching, logistics sorting, sorting, exchange and warehousing in the logistics industry. There are problems such as site limitations, to achieve the effect of expanding the delivery route, good system expansion capability, and high flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

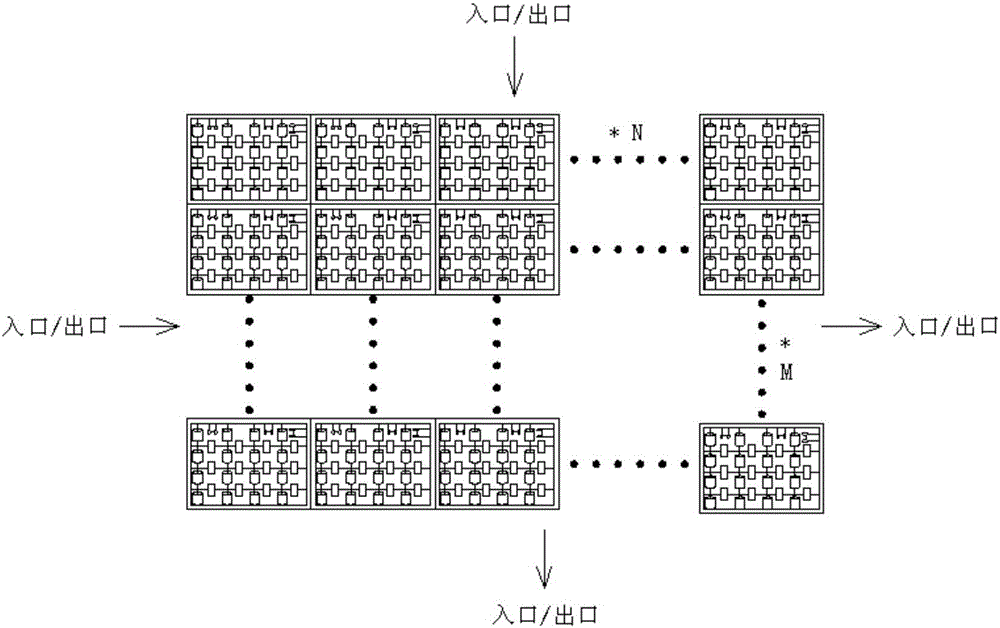

[0043] Such as figure 2 As shown, an array type logistics automatic sorting equipment includes a plurality of sorting units, and the connection and communication between adjacent sorting units are realized through communication interfaces. The sorting units are rectangular and arranged in a matrix. The number of rows of sorting units is M and the number of columns is N. The edges of adjacent sorting units are in contact, so that the two are closely attached to facilitate the smooth delivery of packages. .

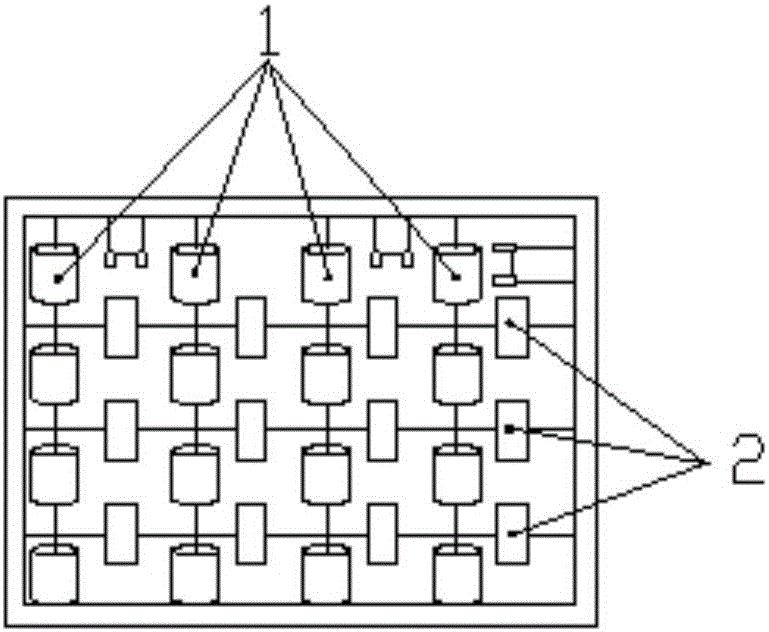

[0044] The structure of the sorting monomer is as figure 1 As shown, the sorting unit includes a main body and a controller (not shown in the figure). The main body is provided with a mobile device that drives the package to move. The controller is connected to the mobile device. The instructions control the movement of the mobile device, and the controllers of adjacent sorting units are connected through the communication interface, so as to realize data transmission an...

Embodiment 2

[0064] The sorting equipment of the present embodiment is the same as the first embodiment, and the working method of the present embodiment comprises the following steps:

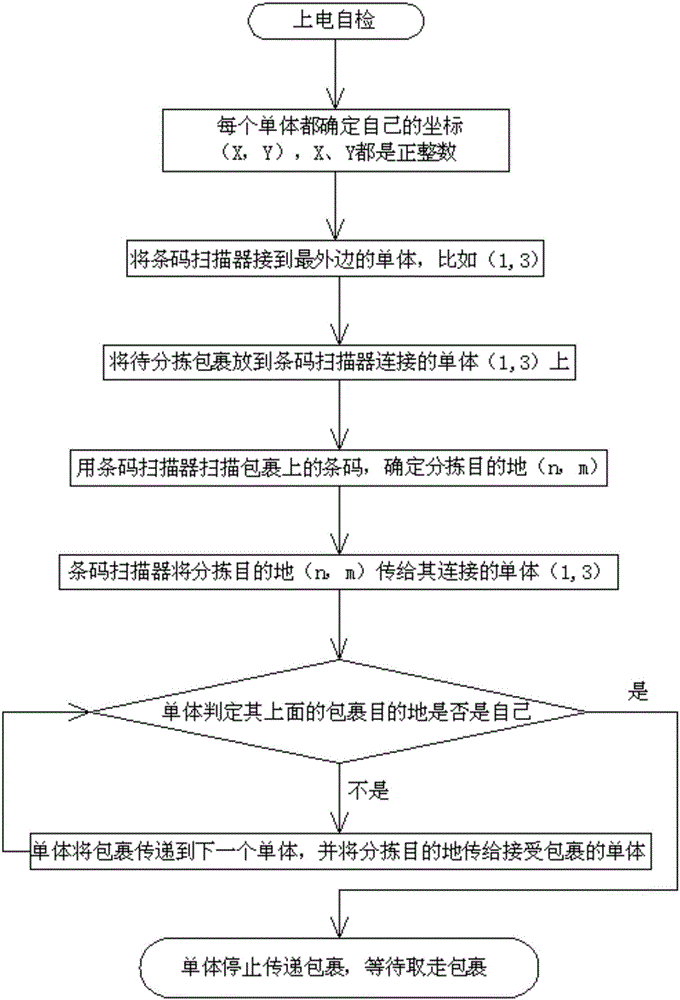

[0065] Step S0: Power on the array logistics automatic sorting equipment of this embodiment to check whether the equipment can operate normally. If the equipment fails, it can be found and eliminated in advance, and then start the sorting work;

[0066] Step S1: each sorting unit in the sorting equipment sets unique corresponding coordinates (X, Y) through the controller, and X and Y are both positive integers;

[0067] Step S2: Connect the barcode scanner to the sort unit located at the outer edge, such as the sort unit whose coordinates are (1,3);

[0068] Step S3: placing the package to be sorted on the sorting unit (1,3) connected to the barcode scanner;

[0069] Step S4: Use a barcode scanner to scan the barcode on the package to determine the sorting destination, and set the coordinates of the packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com