Pulverizer used for pulverizing coal gangue

A pulverizer and coal gangue technology, which is applied in the field of pulverizers for pulverizing coal gangue, can solve the problems of unstable equipment operation, low equipment life, and low production cost, so as to improve efficiency and processing quality, increase service life, and reduce mechanical wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

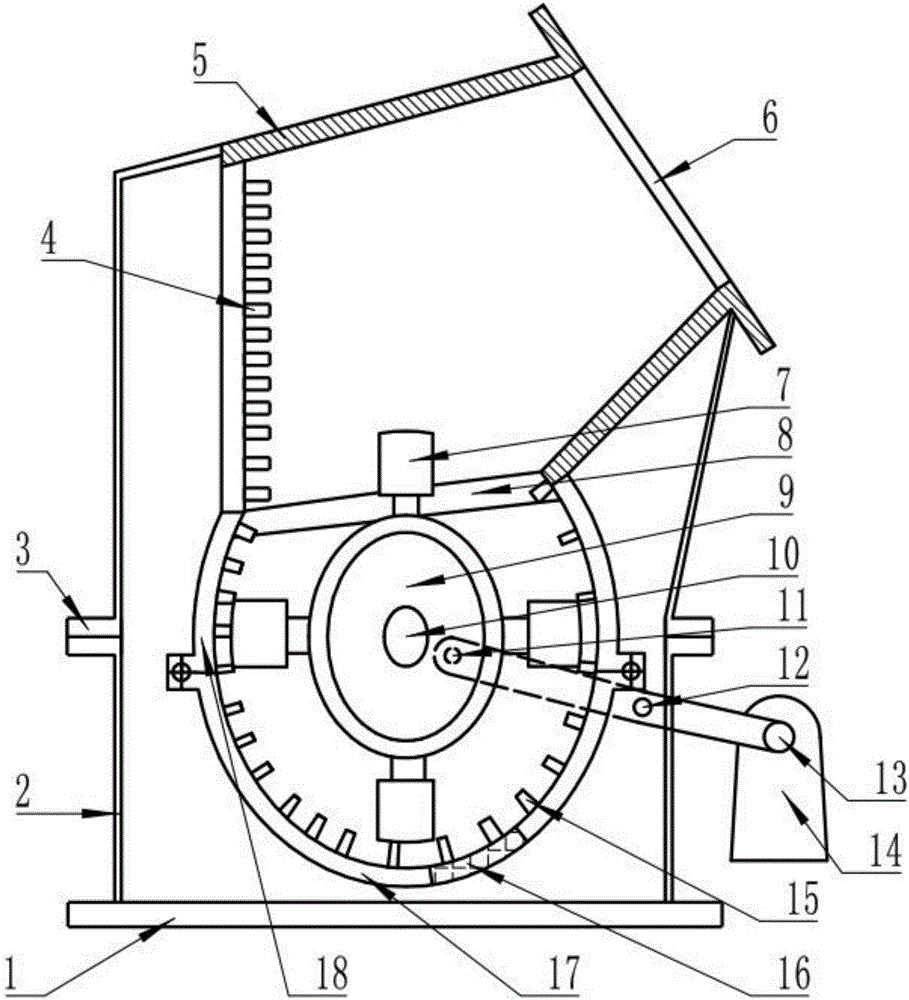

[0021] Such as figure 1 As shown, a pulverizer for crushing coal gangue, the pulverizer is mainly composed of a casing, a crushing bin and a counterweight system; the counterweight system is mainly composed of a lower casing 2, a drum 9, a connecting rod 11 and a counterweight Hammer 14 is formed, and one end of connecting rod 11 is connected with drum 9 through fixed rotating shaft, and the other end of connecting rod 11 is connected with counterweight hammer 14 through pin 13, and the middle part of connecting rod 11 is connected with lower casing 2 through fixed shaft 12.

[0022] When the crusher is working, when it encounters a hard stone, it will cause a greater impact on the equipment and bring a greater acceleration. When the stone cannot be crushed, the equipment will cause an emergency stop, which will cause huge damage to the equipment. destroy. When the drum 9 rotates, it drives the connecting rod 11 to move up and down, and the connecting rod reciprocates left an...

Embodiment 2

[0024] On the basis of Example 1, this embodiment discloses a preferred structure of a pulverizer for pulverizing coal gangue, such as figure 1 As shown, the crushing bin is mainly composed of moving equipment and fixed equipment; the fixed equipment is mainly composed of a material guide channel 5, a connecting cross bar 8, a screen 16, a crushing bin lower shell 17, and a crushing bin upper cover 18. The lower shell 17 of the bin is connected with the upper cover 18 of the crushing bin, the material guide channel 5 is connected with the upper cover 18 of the crushing bin, the material guide channel 5 is provided with a feed port baffle 6; the inner wall of the upper cover 18 of the crushing bin is provided with an upper baffle 4, The inner wall of the lower shell 17 of the crushing bin is provided with a lower baffle plate 15, and the two ends of the connecting bar 8 are respectively connected to both sides of the inner wall of the upper cover 18 of the crushing bin, and the ...

Embodiment 3

[0027] On the basis of Embodiment 2, this embodiment discloses a preferred structure of a pulverizer for pulverizing coal gangue, such as figure 1 As shown, the movement equipment of the crushing bin is mainly composed of a crushing hammer 7, a drum 9 and a rotating shaft 10, the drum 9 is sleeved on the rotating shaft 10, and the rotating shaft 10 is connected to the lower shell 17 of the crushing bin through a bearing; Roller 9 is connected. The crushing hammer has a large mass and high crushing efficiency.

[0028] The shell is mainly composed of a base 1, a lower shell 2 and an upper shell 3, the base 1 is connected to the lower shell 2, the upper shell 3 is connected to the lower shell 2, and the cavity formed by the base 1, the lower shell 2 and the upper shell 3 will be crushed Warehouse package included. The casing wraps the crushing chamber, which not only reduces the processing noise of the equipment, but also improves the structural stability of the equipment. Ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com