Bladeless stirrer

A stirrer and disc technology, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc., to achieve the effects of saving land, shortening curing time, and improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

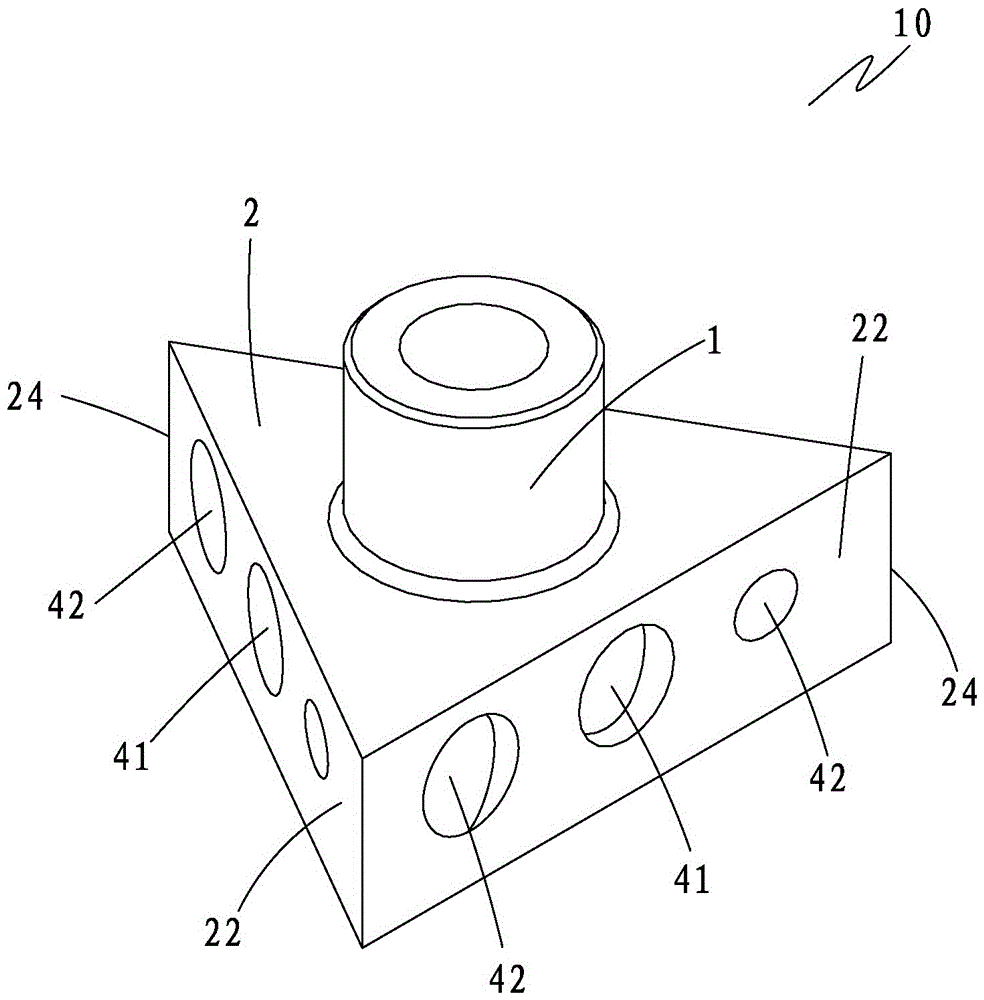

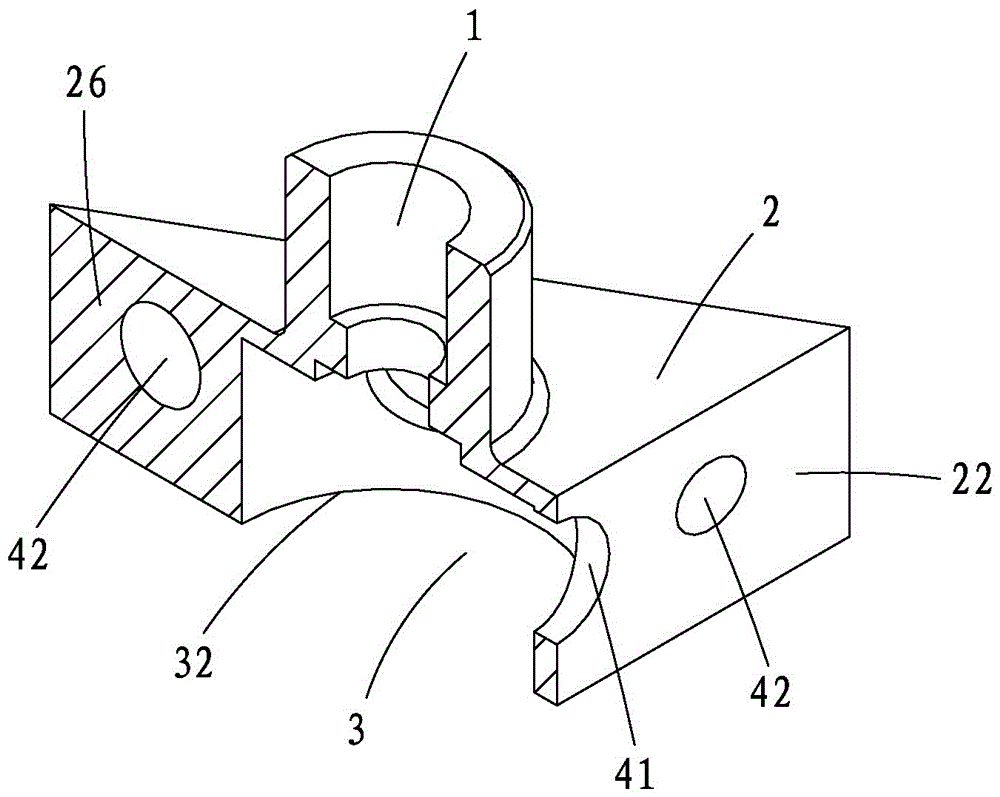

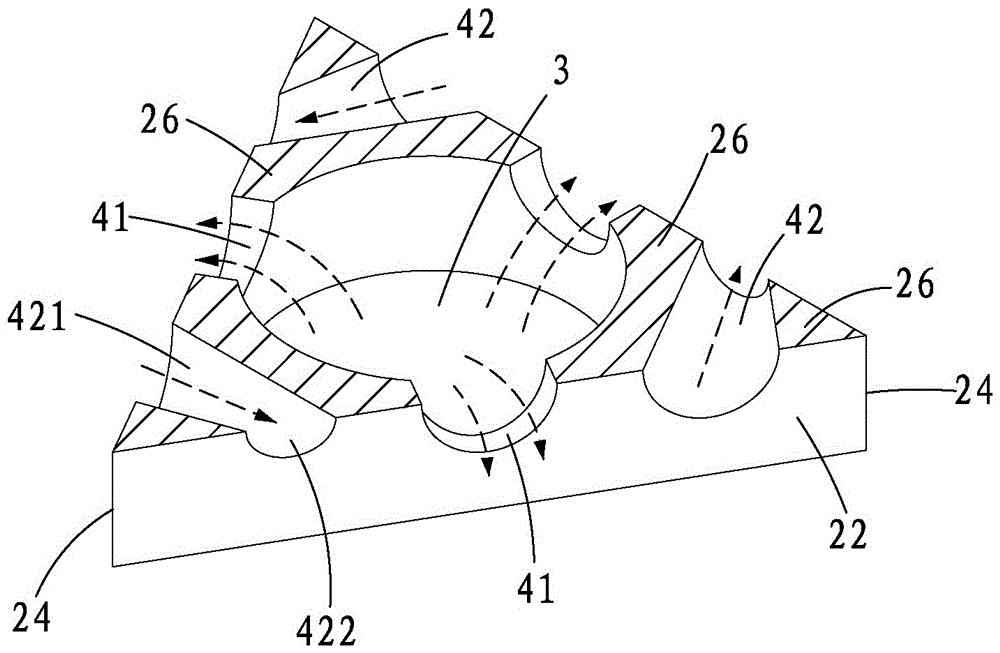

[0023] see Figure 1 to Figure 8 As shown, the wingless agitator 10 of the present invention includes a shaft sleeve 1 and a disc body 2, and the disc body 2 is connected to the stirring shaft 20 of the agitator through the shaft sleeve 1, and the disc body 2 is not provided with stirring blades, and the outer surface of the disc body 2 is composed of a plurality of planes 22 connected in sequence, and a stirring corner 24 is formed at the junction of every two planes 22 .

[0024] The profile structure of the disc body 2 is a regular polygonal column structure, wherein it is better to use an equilateral triangular column structure or a regular quadrilateral column structure, that is, when the disc body 2 is an equilateral triangular column structure or a regular quadrilateral column structure, its The smaller the angle of the stirring corners 24, the better the stirring effect. On the contrary, the more the number of stirring corners 24, the larger the angle of the stirring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com