Method for preparing soybean paste

A soybean paste and soybean technology, applied in food preparation, application, food science, etc., can solve the problems of long immersion time, loss of water-soluble nutrients, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

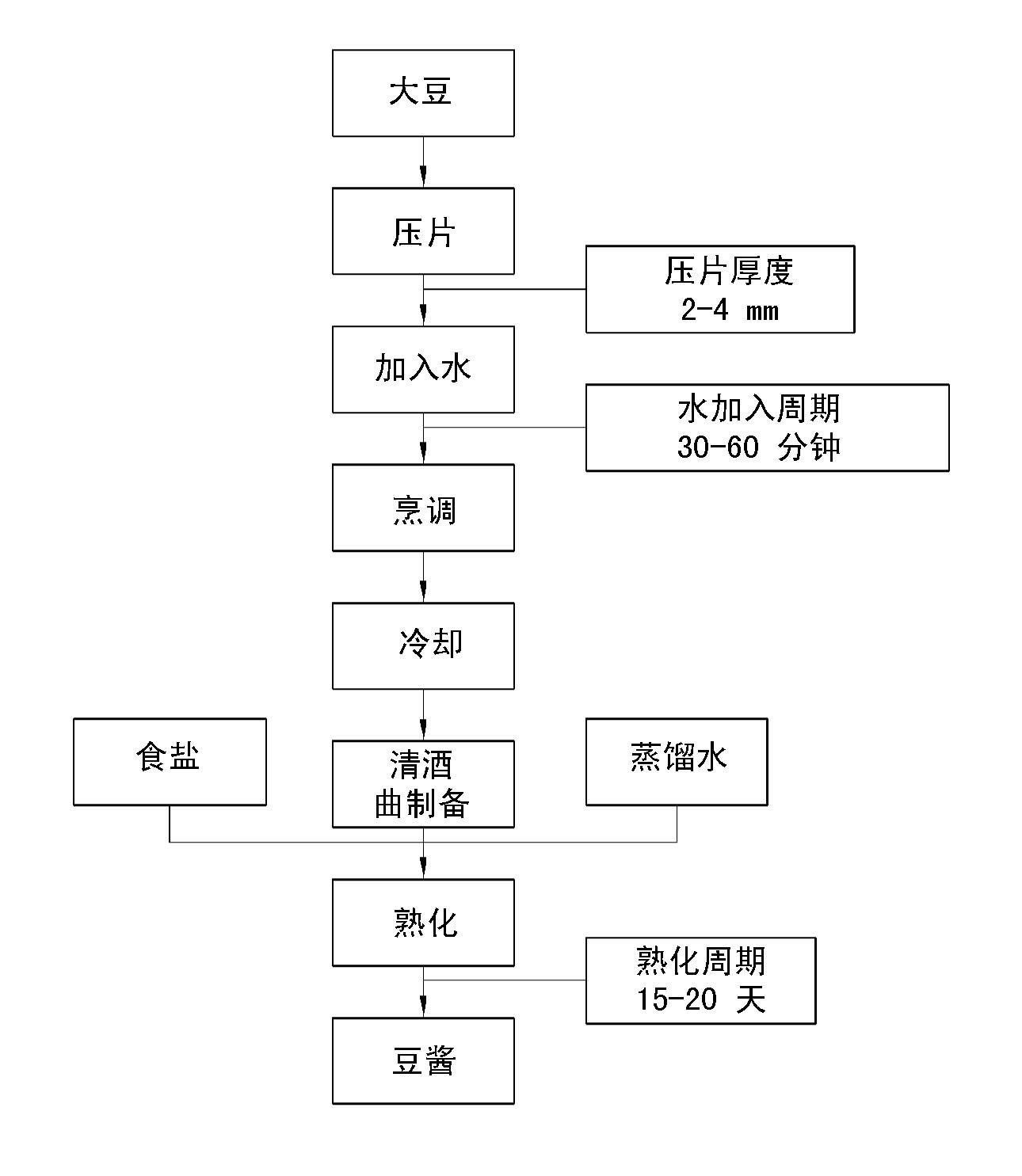

[0030] Example 1: Preparation of tempeh using flaked soybeans

[0031] Raw soybeans are rolled into flakes with a thickness of 2-4mm, and then soaked in water at room temperature (25°C) for 6-14 hours to adjust the water content of soybeans to 55-60% (w / w). The hydrated soybeans were cooked at 120°C for 30 minutes, then continued to cool down to 35°C, and mixed with 0.3wt% of koji bacteria and 1.0wt% of soybean flour relative to the weight of the soybeans, and the surface of the pressed soybeans was inoculated with resulting mixture. Soybeans were grown for the first 24 hours while maintaining a material temperature of 30°C and a relative humidity of 90%. Then, sake koji was prepared from soybeans while maintaining a material temperature of 25°C and a relative humidity of 40% for 36-40 hours.

[0032] Therefore, the period of maximum water absorption of the compressed soybeans is 60 minutes, which corresponds to a 7-fold reduction compared with 7 hours in the conventional case...

Embodiment 2

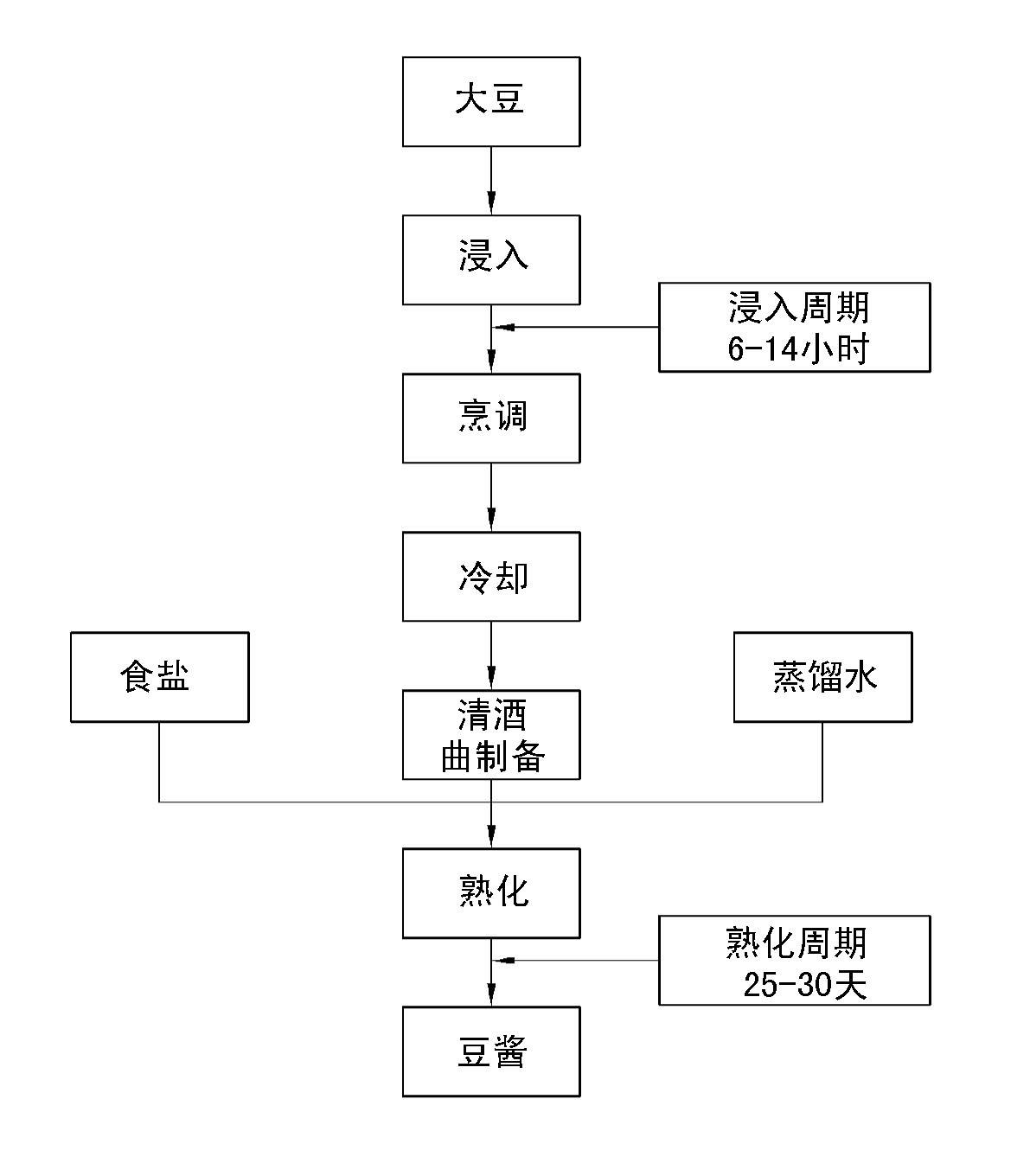

[0035] Embodiment 2: use conventional method to prepare fermented soya bean

[0036] Soybeans were washed with water, immersed in water at a temperature of 25°C for 7 hours, cooked at 120°C, continued to cool to 35°C, and inoculated with a mixture of 0.3wt% koji bacteria and 1.0wt% soybean flour relative to the weight of the soybeans.

[0037] Soybeans were grown for the first 24 hours while maintaining a material temperature of 30°C and a relative humidity of 90%. Then, sake koji was prepared from soybeans while maintaining a material temperature of 25° C. and a relative humidity of 40% for the entire 36-40 hours.

[0038] The hydration and cooking cycles of spherical soybeans are shown in Tables 1 and 2.

[0039] The protease of conventional modified tempeh was measured, and the results obtained thereby are shown in Table 3.

[0040] Table 1

[0041] [Table 1]

[0042] Changes in water content of flaked soybeans under each immersion cycle (unit: wt%)

[0043] I...

Embodiment 3

[0060] Example 3: Preparation of soybean paste using pressed soybeans

[0061] The 63.64wt% improved fermented soya bean prepared in Example 1 (based on 45wt% fermented soya bean moisture) was mixed with 24.36wt% distilled water and 12.00wt% salt, and the resulting mixture was matured at room temperature for 22 days to prepare soybean paste. As a result, the soy paste prepared from the pressed soybeans had a ripening degree of 501 mg% (22 days in terms of maturing time), which was increased by 52% compared with the conventional improved soy paste, and decreased by 2.2% compared with the conventional improved soy paste. times or higher curing time (based on a curing time of 22 days).

[0062] The ripening degree of the modified soybean paste prepared from the flaked soybeans was measured, and the results obtained therefrom are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com