PVC filter plate

A filter plate and filter screen technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of short service life, poor wear resistance and corrosion resistance of metal materials, and achieve simple production, rapid filtration, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

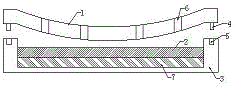

[0011] A PVC filter plate, comprising a PVC panel 1, a filter screen 2 and a bottom plate 3; a clip 4 is provided on the lower surface of the PVC panel; a card slot 5 is provided on the bottom plate, and the filter screen 2 is arranged between the PVC panel 1 and the bottom plate 3; The PVC panel 1 is a concave arc-shaped structure, and a plurality of through holes 6 are arranged on the PVC panel; the bottom plate 3 is a U-shaped structure, and a water-absorbing layer 7 is arranged inside the bottom plate, and drainage holes are arranged on the bottom plates on both sides of the water-absorbing layer 7 8.

[0012] The water-absorbing layer 7 is a sponge layer.

[0013] More than four through holes 6 are arranged on the PVC panel 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com