Preparation method of special half-dried flour for physalis alkekengi rice noodles

A technology of physalis rice noodle and semi-dry powder, which is applied in the field of grain deep processing, can solve the problems of material loss, low removal rate of lead and mercury, and no method for removing cadmium, etc., and achieve high quality, low cost and wide range of heavy metal reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Get the rice (lead content is 0.2ppm, mercury content is 0.02ppm, cadmium content is 0.2ppm, arsenic content is 0.2ppm) that heavy metal exceeds the standard and carry out the following steps:

[0032] (1) soak rice for acid adjustment: soak the rice in water, the ratio of solid to liquid is 1:1, adjust the pH to 4.0 with the acid adjustment solution, and the acid adjustment solution is; the mixture of lactic acid and glacial acetic acid (the mol ratio of lactic acid and glacial acetic acid is 2 : 1) compound acid formed with hydrochloric acid, wherein the mol ratio of mixture and hydrochloric acid is 3:1;

[0033] (2) Add lactic acid bacteria: add lactic acid bacteria in the feed liquid of step (1), the addition amount is 5×10 6 cfu / g (according to rice mass);

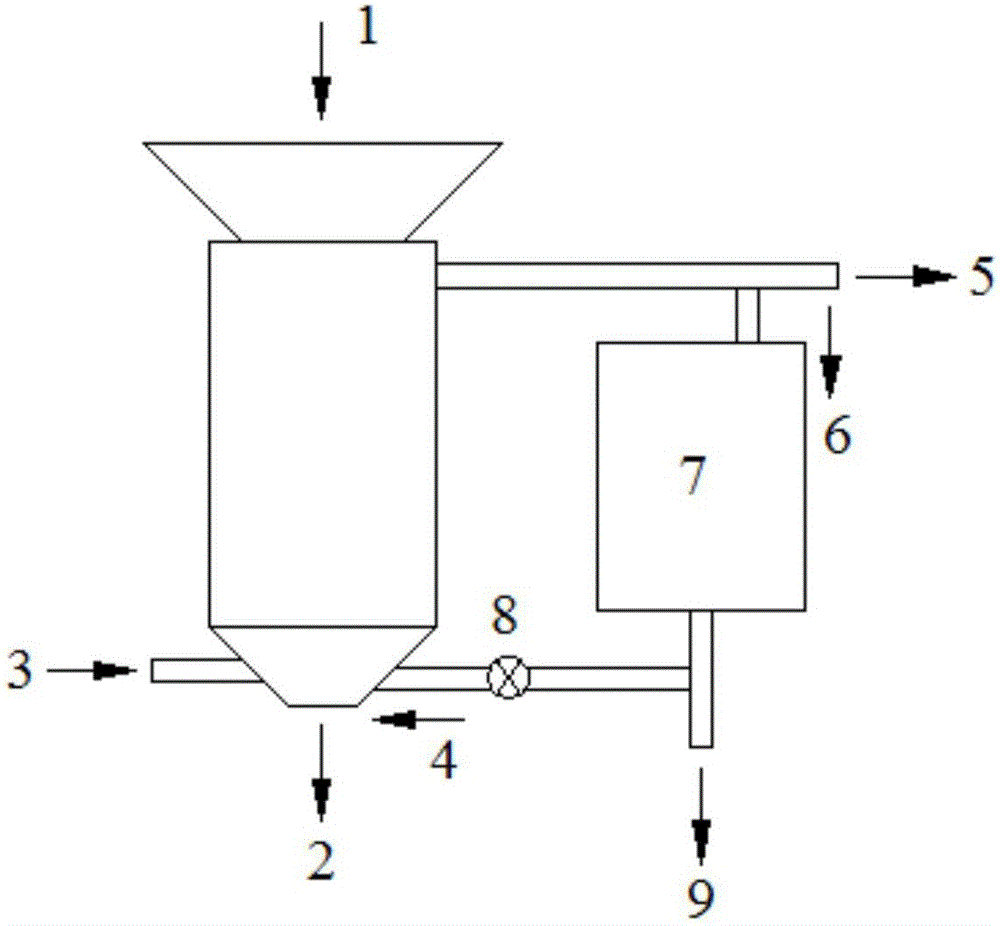

[0034] (3) Dynamic countercurrent fermentation: Add the feed liquid containing the bacteria in step (2) to the countercurrent device that has sterilized the bacteria, set the fermentation temperature to 45°C, ...

Embodiment 2

[0041]Get the rice (lead content is 0.3ppm, mercury content is 0.03ppm, cadmium content is 0.8ppm, arsenic content is 0.4ppm) that heavy metal exceeds the standard and carry out the following steps:

[0042] (1) soaking rice for acid adjustment: soak the rice in water, the ratio of solid to liquid is 1:1.1, adjust the pH to 4.5 with the acid adjustment solution, and the acid adjustment solution is a mixture of three acids: citric acid, malic acid and fumaric acid ( Citric acid, malic acid, fumaric acid molar ratio is 1:2:1) and the composite acid of hydrochloric acid, wherein the molar ratio of mixture and hydrochloric acid is 4:1;

[0043] (2) Adding lactic acid bacteria: adding lactic acid bacteria to the feed liquid in step (1), the addition amount is 6×10 6 cfu / g (according to rice mass);

[0044] (3) Dynamic countercurrent fermentation: Add the feed liquid containing the bacteria in step (2) into the countercurrent device that has sterilized the bacteria, set the ferment...

Embodiment 3

[0051] Get the rice (lead content is 0.4ppm, mercury content is 0.04ppm, cadmium content is 2ppm, arsenic content is 0.6ppm) that heavy metal exceeds the standard and carry out the following steps:

[0052] (1) Sour rice acid adjustment: rice is soaked in water, the ratio of material to liquid is 1:1.2, and the pH is adjusted to 5.0 with the acid adjustment solution, and the acid adjustment solution is; a mixture of tartaric acid, metatartaric acid, citric acid (tartaric acid, metatartaric acid, The compound acid that citric acid mol ratio is 3:2:1) and hydrochloric acid forms, and wherein the mol ratio of mixture and hydrochloric acid is 5:1;

[0053] (2) Add lactic acid bacteria: add lactic acid bacteria to the feed liquid in step (1), the addition amount is 7×10 6 cfu / g (according to rice mass);

[0054] (3) Dynamic countercurrent fermentation: Add the feed liquid containing the bacteria in step (2) to the countercurrent device that has sterilized the bacteria, set the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com