Workplace type wheat germ compound milk powder and preparation method thereof

A technology of wheat germ powder and wheat germ, which is applied in dairy products, milk preparations, applications, etc., can solve the problems of no research on wheat germ protein foods, no consideration of product state stability, taste flavor and protein absorption rate, etc. , to improve the body's immunity, maintain nutritional value, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

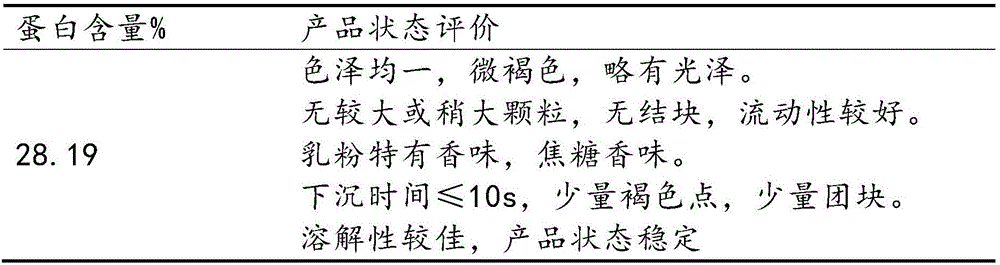

Embodiment 1

[0030] Workplace type wheat germ compound milk powder 1 includes the following components: 500g skim milk powder, 104g enzymatically hydrolyzed wheat germ powder, 176g white sugar, 9g microcrystalline cellulose, 42g whey protein powder, 169g soybean powder, each component Both are dry powders, in which the protein content of skimmed milk powder is 32%, the content of casein is 25%, the content of whey protein is 5.4%, the content of wheat germ protein in the enzymatically hydrolyzed wheat germ powder is 30%, and the content of whey protein is 30%. The whey protein content in protein powder is 85%, the soybean protein content in soybean powder is 37%, and the ratio of casein:whey protein:soy protein:wheat germ protein is about 2:1:1:0.5.

[0031] The preparation method of workplace type wheat germ compound milk powder 1 comprises the steps:

[0032] (1) Take 104g of enzymatically hydrolyzed wheat germ powder and bake at 45°C for 10 minutes, then add dry 500g of skimmed milk pow...

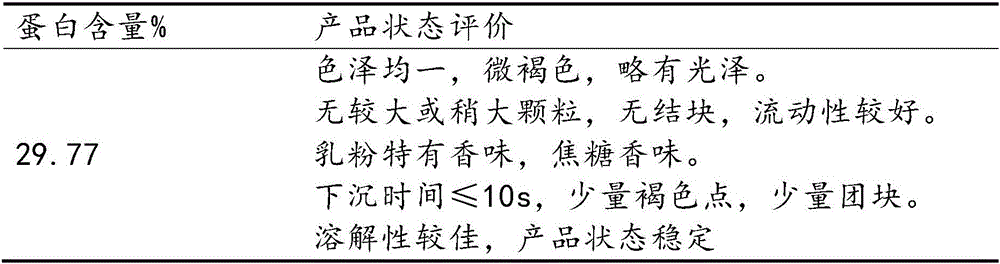

Embodiment 2

[0047] Workplace type wheat germ compound milk powder 2 includes the following components: 450g skim milk powder, 70g enzymatically hydrolyzed wheat germ powder, 240g white sugar, 15g microcrystalline cellulose, 100g whey protein powder, 125g soybean powder, each component All dry powder.

[0048] The preparation method of workplace type wheat germ compound milk powder 2 is as follows:

[0049] (1) Take 70g of dry enzymatically hydrolyzed wheat germ powder and bake at 50°C for 5 minutes, then add dry 450g of skimmed milk powder to the dry mixer for mixing, set the speed of the dry mixer to 2000r / min, and the mixing time is 5min, to obtain the premix 2;

[0050] (2) Take dry 100g whey protein powder, 125g soybean powder, 240g white granulated sugar and 15g microcrystalline cellulose and grind them. The diameter of the pulverized powder is less than 800 μm. Put the pulverized powder into the dry mixer, and then add (1) For premix 2, set the speed of the dry mixer to 2000r / min,...

Embodiment 3

[0055] Workplace type wheat germ compound milk powder 3 includes the following components: 550g skimmed milk powder, 150g enzymatically hydrolyzed wheat germ powder, 75g white sugar, 5g microcrystalline cellulose, 20g whey protein powder, 200g soybean powder.

[0056] The preparation method of workplace type wheat germ compound milk powder 3 is as follows:

[0057] (1) Take 150g of dry enzymatically hydrolyzed wheat germ powder and bake at 30°C for 30 minutes, then add dry 550g of skimmed milk powder to the dry mixer for mixing, set the speed of the dry mixer to 1000r / min, and the mixing time is 30min to obtain premix 3;

[0058] (2) Take dry 20g of whey protein powder, 200g of soybean powder, 75g of white granulated sugar and 5g of microcrystalline cellulose and grind them. The particle diameter of the pulverized powder is less than 100 μm. Put the pulverized powder into a dry mixer, and then add (1) For premix 3, set the speed of the dry mixer to 1000r / min, and the mixing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com