Rice seedling raising substrate mould pressing production line

A technology for seedling substrates and production lines, applied in planting substrates, culture medium, horticulture, etc., can solve the problems of long processing cycle, many manual processing processes, unsatisfactory molding effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

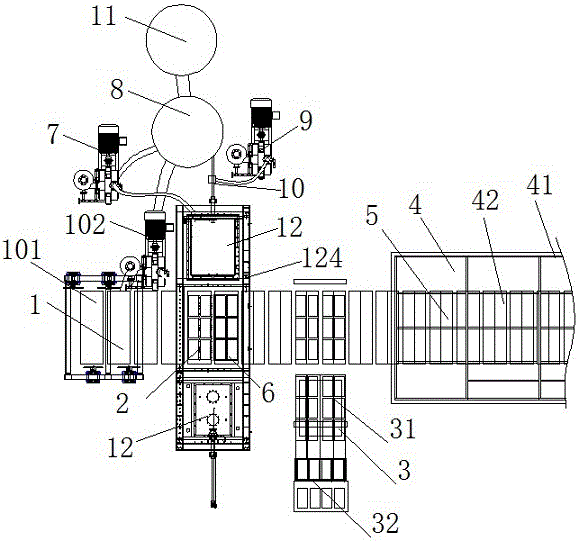

[0021] Such as figure 1 As shown, the rice seedling raising substrate molding production line includes a homogenizing unit 1, a molding machine 2, a dry sheet collecting and bundling unit 3 and a drying unit 4 connected in sequence by a transmission network chain 5, wherein: the homogenizing unit 1 includes a homogenizing unit 1 The slurry machine 101 and the slurry pipeline pump 102, the slurry pipeline pump 102 will transfer the uniform slurry stirred by the homogenizer to the buffer tank 8; the compression molding machine 2 includes two mold chambers 12 located on the side of the transmission network chain 5; the mold chamber 12. Get the suspension from the buffer tank 8 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com