Permanent magnet synchronous motor for compressor

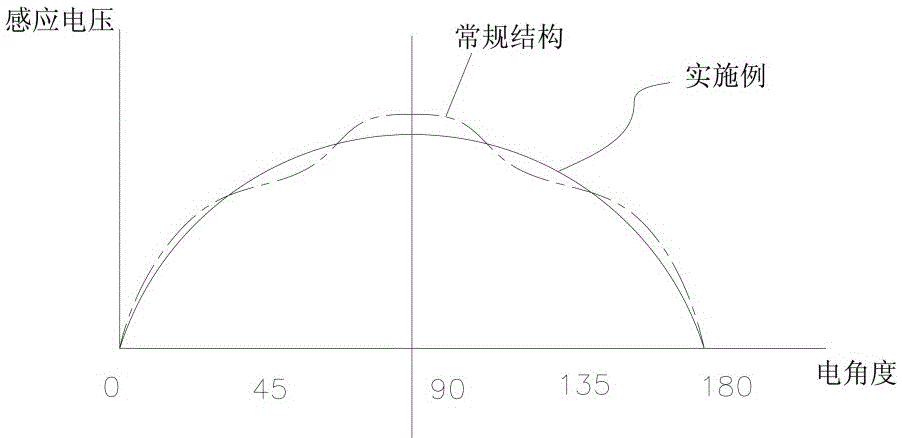

A synchronous motor, permanent magnet technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, synchronous machine parts, etc. Motor efficiency and other issues, to achieve the effect of improving noise, improving efficiency, and reducing motor cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

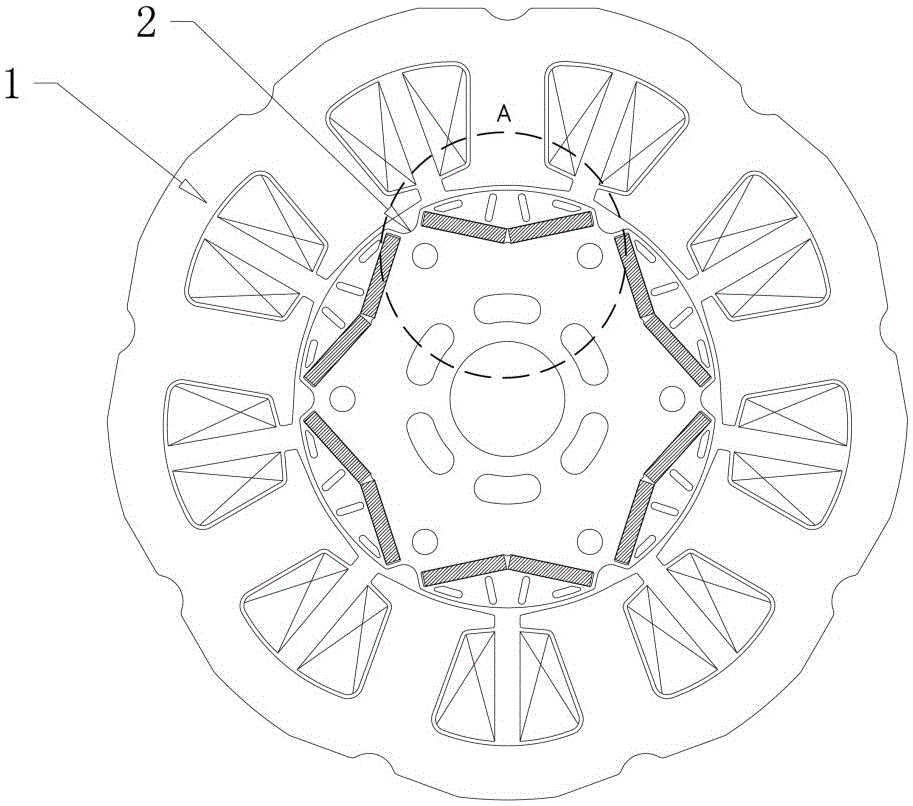

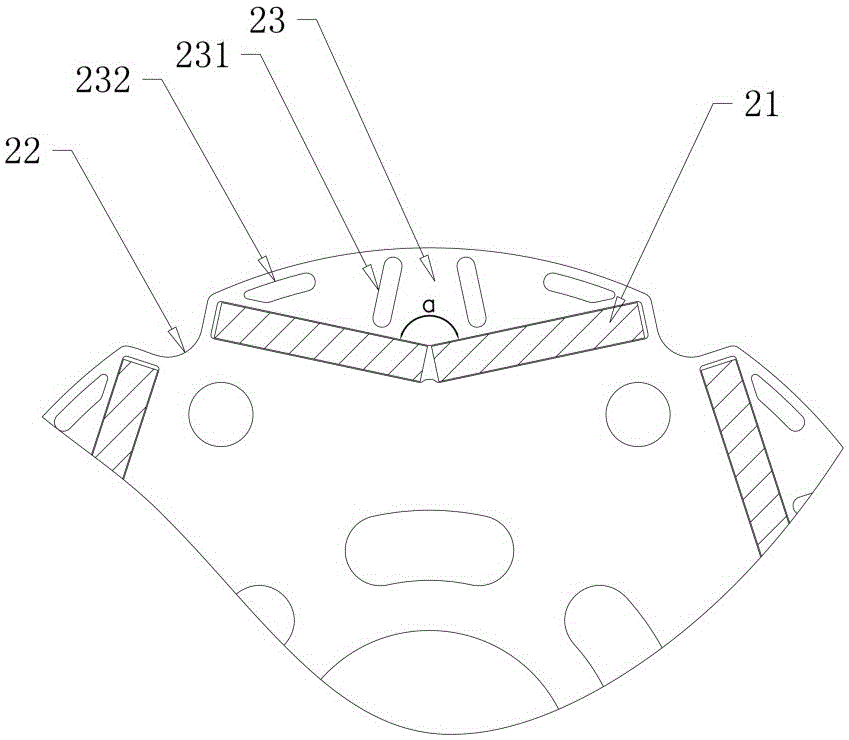

[0018] See attached figure 1 And attached figure 2 As shown, in this embodiment, a permanent magnet synchronous motor used in a compressor includes a stator 1 and a rotor 2 composed of laminated electromagnetic steel plates, wherein, according to the specifications of the permanent magnet synchronous motor, different thicknesses are selected. Electromagnetic steel plate, the thickness of the common electromagnetic steel plate used for motors is 0.3~0.5mm. The rotor 2 is set inside the stator 1 and there is an air gap between the stator 1 and the rotor 2; the end surface of the rotor 2 is provided with a plurality of magnet accommodation grooves 21 in a "V" shape distributed in the circumferential direction and extending along the length direction of the rotor 2 , wherein, the angle between the two sides of the magnet accommodating groove 21 faces the outer diameter of the rotor 2; the angle α between the two sides of the magnet accommodating groove 21 is 90°-170°. Permanent...

Embodiment 2

[0022] See attached Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that there are two sets of first slit hole groups 231, wherein the two sets of first slit hole groups 231 each include two The axis of symmetry is symmetrically distributed in the first slot holes in the middle of the slot part 23; in this way, multiple sets of first slot hole groups 231 are set on the slot part 23, so that the magnetic flux in the air gap part between the stator 1 and the rotor 2 The density distribution is smoother in the circumferential direction, thereby reducing the noise and vibration of the permanent magnet synchronous motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com