Robot-based power station inspection system and robot-based power station inspection method

A patrol inspection system and robot technology, applied in the electrical and electromechanical fields, can solve the problems of inspection personnel danger, complex environment, heavy workload, etc., and achieve the effect of ensuring accuracy and consistency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

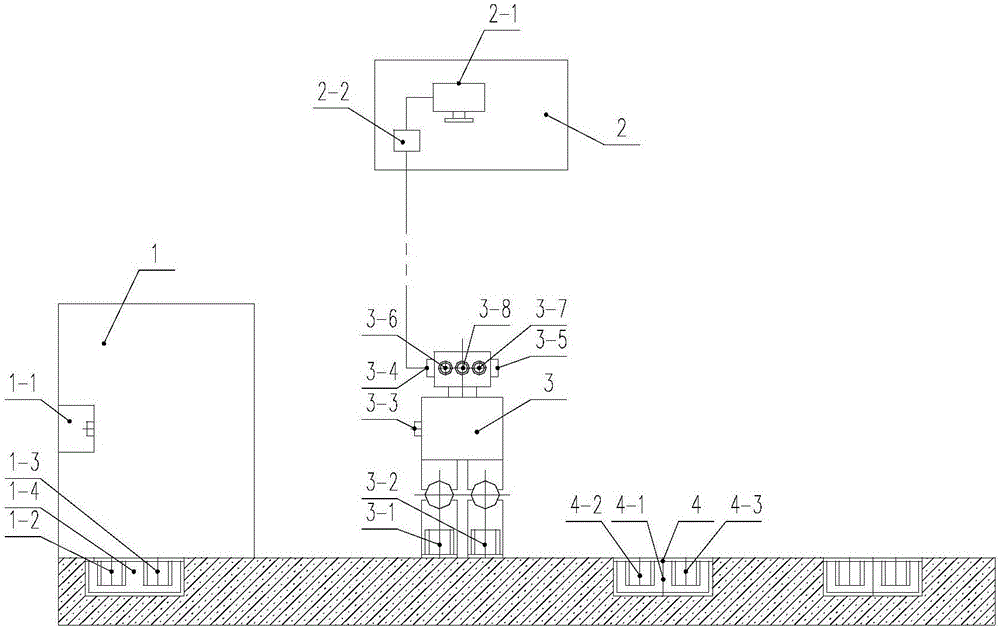

[0020] like figure 1 As shown, a robot power station inspection system includes a robot base station 1, a main control room 2, an inspection robot 3, and an inspection point 4; the robot base station 1 is provided with a base station charging stand 1-1 and a base station optical positioning signal switch 1-4, the base station optical positioning signal switch 1-4 includes the base station optical signal left switch 1-2 and the base station optical signal right switch 1-3; the main control room 2 is equipped with a main control computer 2-1 and a main control Room signal remote switch 2-2; the bottom of the left foot of the inspection robot 3 is provided with a robot left foot optical signal switch 3-1, and the bottom of the right left foot of the inspection robot 3 is provided with a robot right foot optical signal switch 3-2 The left side of the middle part of the inspection robot 3 is provided with an inspection robot charging head 3-3, and the left side of the head of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com