Low-voltage capacitor element replacing device for 500kV transformer station

A low-voltage capacitor and substation technology, applied in the field of low-voltage capacitor element replacement devices for 500kV substations, can solve problems such as complex structure and cumbersome operation process, and achieve the effects of improving safety, saving labor load, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

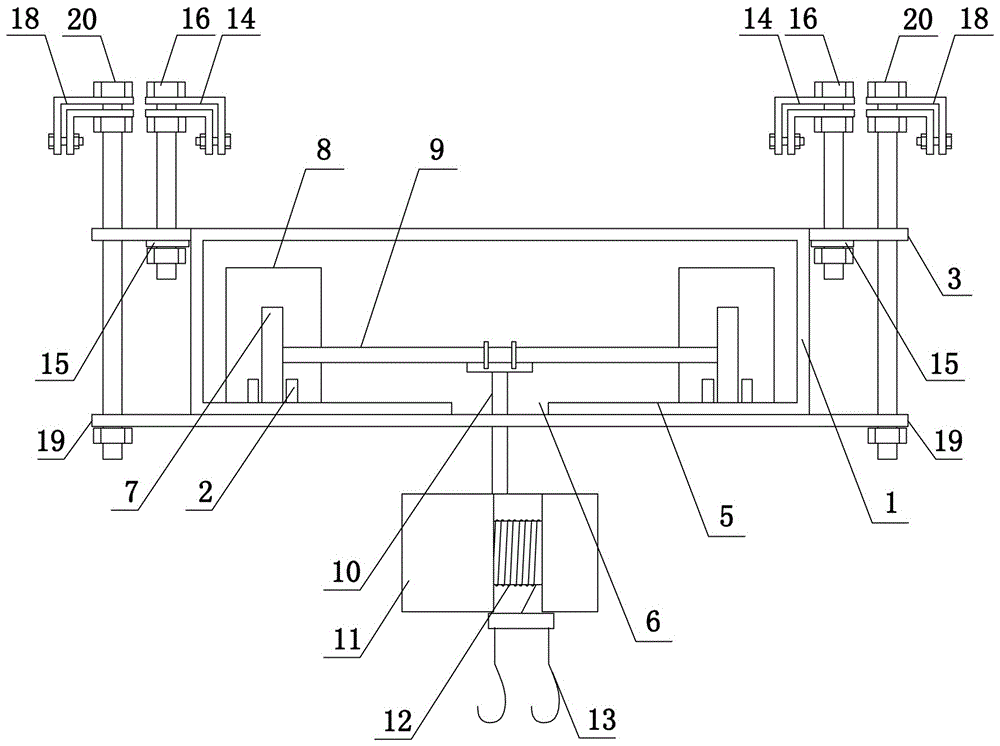

[0039] Such as Figure 2 to Figure 6 Shown, the present invention comprises walking mechanism and supporting hanging mechanism:

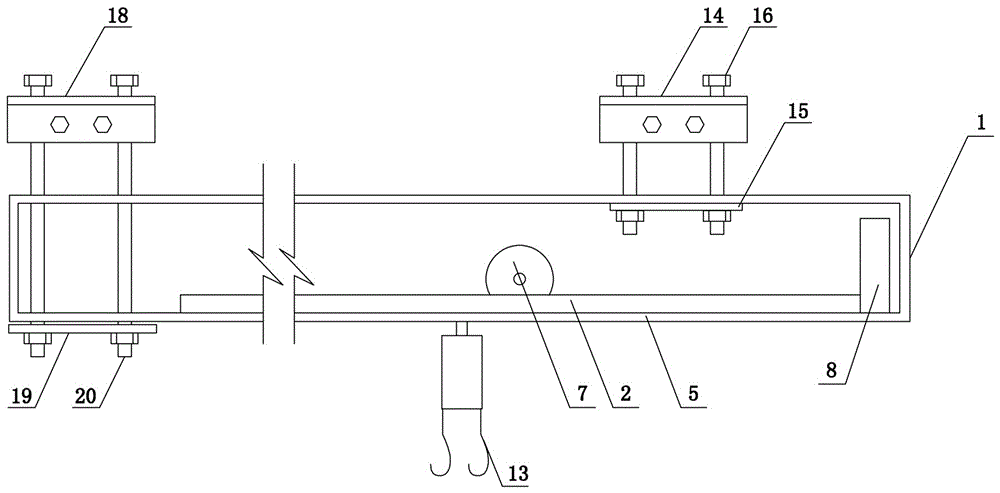

[0040] The traveling mechanism comprises a rectangular parallelepiped frame 1 and guide rails 2. Extension plates 3 are arranged on both sides of the upper end of the rectangular parallelepiped frame 1. The extension plate 3 is provided with a through hole 4. There are multiple through holes 4. The lower end of the rectangular parallelepiped frame 1 is welded with a bottom plate 5. The strip hole 6 and the guide rail 2 are fixedly welded on the upper end surface of the bottom plate 5. The two guide rails 2 are respectively located on both sides of the strip hole 6. Rollers 7 are installed on the two guide rails 2, and the front ends of the two guide rails 2 are both limited. The position block 8 and the limit block 8 are made of rubber. A support rod 9 is installed between the two rollers 7. A suspender 10 is arranged on the support pole 9. The lowe...

Embodiment 2

[0043] The traveling mechanism comprises a rectangular parallelepiped frame 1 and guide rails 2. Extension plates 3 are arranged on both sides of the upper end of the rectangular parallelepiped frame 1. The extension plate 3 is provided with a through hole 4. There are multiple through holes 4. The lower end of the rectangular parallelepiped frame 1 is welded with a bottom plate 5. The strip hole 6 and the guide rail 2 are fixedly welded on the upper end surface of the bottom plate 5. There are two guide rails 2, which are respectively located on both sides of the elongated hole 6. Rollers 7 are installed on the two guide rails 2, and the rollers 7 have a built-in drive motor 21. The driving motor 21 is a permanent magnet motor. The power supply 22 and the control switch 23 are installed on the rectangular parallelepiped frame 1. The power supply 22 can use a 36V rechargeable lithium battery. The control switch 23 is a forward and reverse switch. 8. The limit block 8 is made of...

Embodiment 3

[0047] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 9 As shown, the through hole 4 on the extension plate 3 is a long strip structure, and the extension direction of the through hole 4 is perpendicular to the extension direction of the guide rail 2. This structure design can make the electric hoist 11 install electric power by fine-tuning the cuboid frame 1 left and right during installation. Directly above the capacitor, that is, the cuboid frame 1 is preliminarily fixed through the front threaded suspender 16 and the rear threaded suspender 20 during the use process, and then the position of the electric hoist 11 and the position of the power capacitor are combined to fine-tune the cuboid frame 1 left and right. The calibration of the cuboid frame 1 is realized without dismantling multiple front threaded suspenders 16 and rear threaded suspenders 20, effectively improving the operating efficiency of the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com