All-fiber structure high-energy rectangular laser pulse generation system and method

A technology of laser pulses and rectangular pulses, applied in the field of lasers, can solve problems such as the difficulty of directly outputting high-energy pulses, and achieve the effects of insensitivity to environmental disturbances, high conversion efficiency, and mature preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

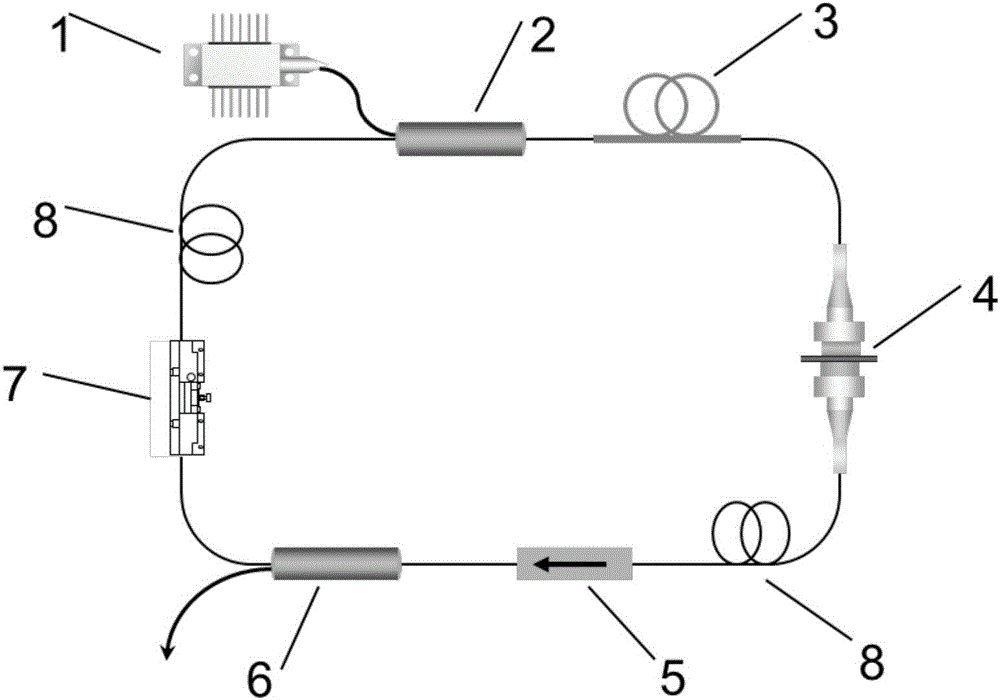

[0046] The invention provides a high-energy rectangular laser pulse generation system with an all-fiber structure, such as figure 1 As shown, it includes a pump source 1, a wavelength division multiplexer 2, an ytterbium-doped gain fiber 3, a novel saturable absorber 4, a polarization-independent isolator 5, an output coupler 6 and a polarization controller 7. A wavelength division multiplexer 2, an ytterbium-doped gain fiber 3, a new saturable absorber 4, a polarization-independent isolator 5, an output coupler 6, and a polarization controller 7 are sequentially connected through a single-mode fiber 8 in a closed loop. The pump source 1 is connected to the input end of the wavelength division multiplexer 2, and the output end of the output coupler 6 outputs a rectangular pulse.

[0047] Wherein, the pumping source 1 is a semiconductor laser or a fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com