A kind of cathode material for lithium-sulfur battery and using method thereof

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, electrode carriers/collectors, etc., can solve problems such as poor ion and electron conductivity, reduced energy conversion efficiency, and reduced battery energy density. Guaranteed cycle stability, cycle stability guarantee, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

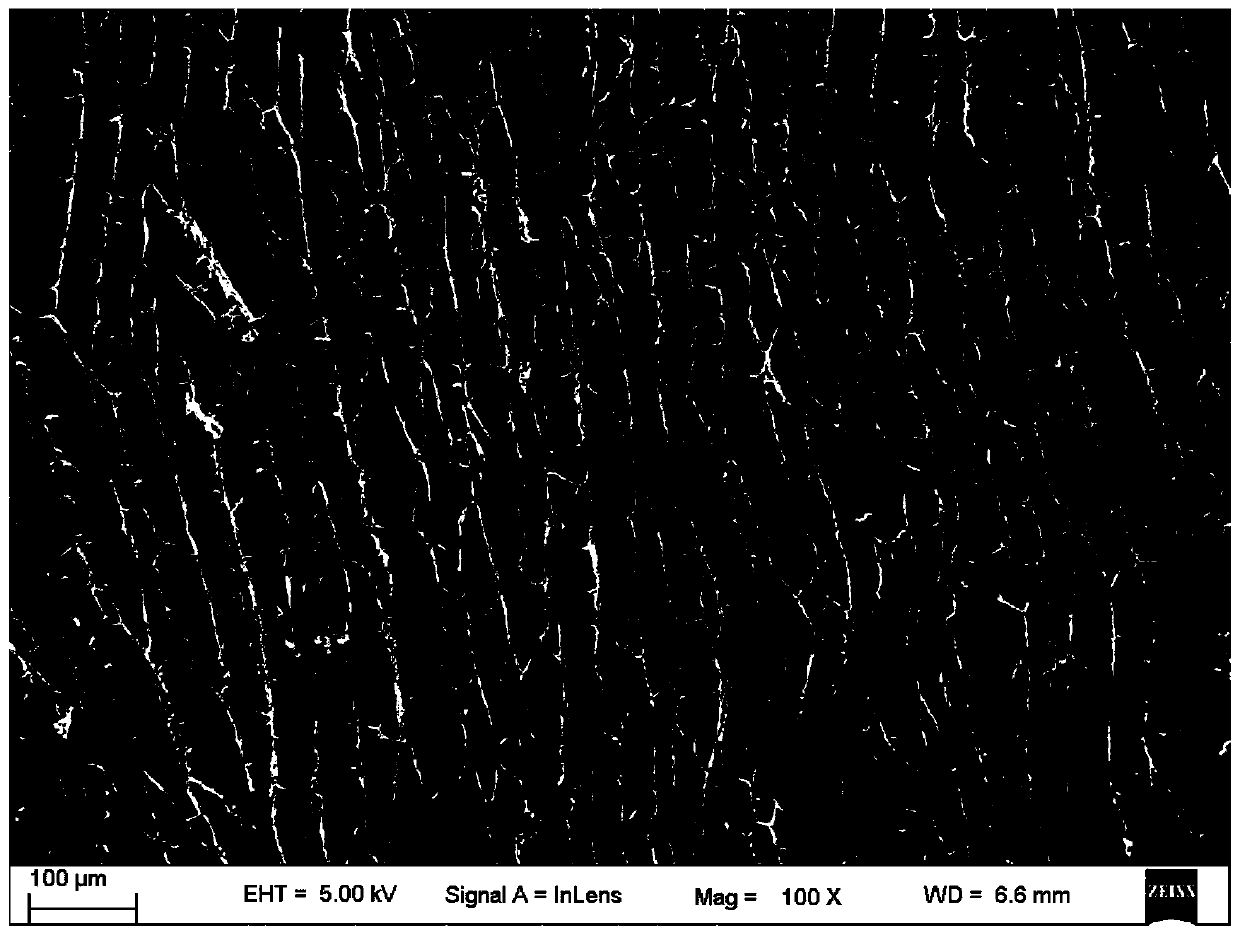

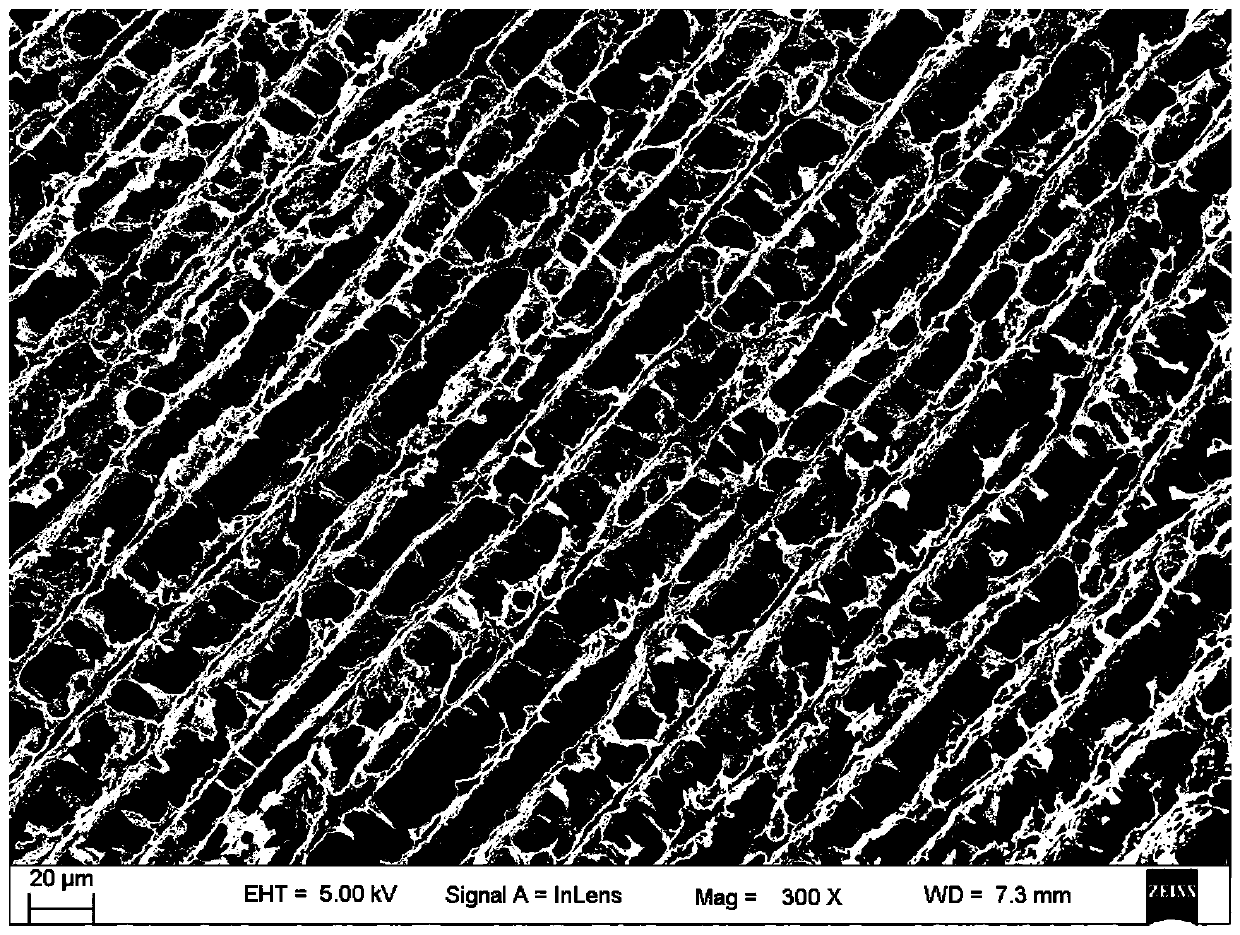

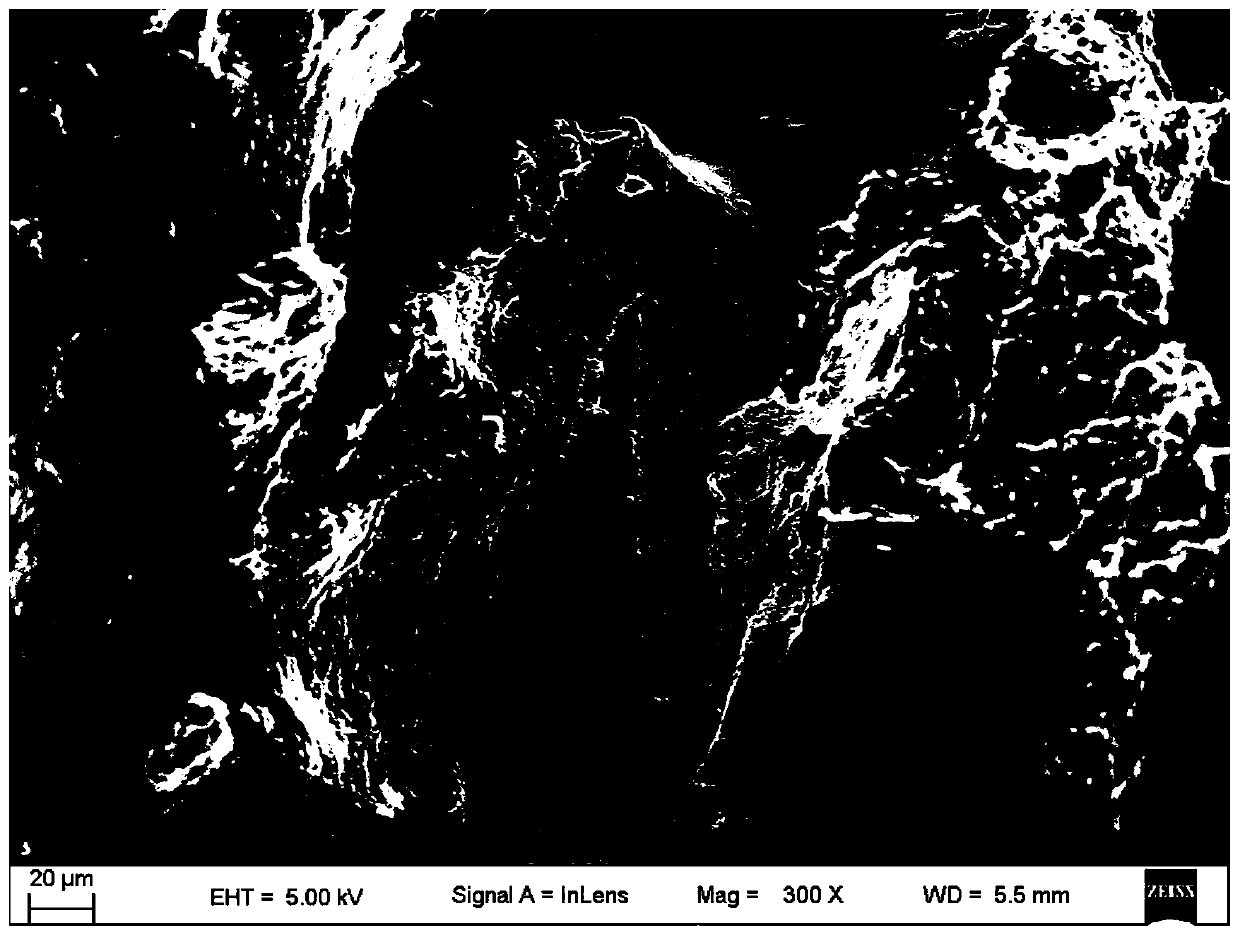

[0024] Preparation of sheet-like carbon nanotube bulk material: inject 5wt% carbon nanotube aqueous slurry into the designed mold, the mass fraction of polyvinylpyrrolidone in the slurry is 1.2wt%, and then mold the mold at a rate of 50cm / h Immerse in constant temperature liquid nitrogen at -196°C at a high speed. After the slurry is completely solidified, quickly transfer it to a freeze dryer, and freeze-dry it at -5°C with a final vacuum of 1Pa. Cross-sectional SEM of layered carbon nanotube bulk material such as figure 1 with 2 shown. The thickness of the sheets is 10 μm, and the distance between adjacent sheets is 200 μm.

[0025] Pre-shaping of carbon nanotube block material: place the above-mentioned carbon nanotube block material between two highly flat stainless steel ingots, and place the direction so that the layer direction of the carbon nanotube block material is parallel to the stainless steel plane. The above-mentioned carbon nanotube bulk material is then com...

Embodiment 2

[0028] Preparation of sheet-like carbon nanotube bulk material: inject 1wt% carbon nanotube aqueous slurry into the designed mold, the mass fraction of polyvinylpyrrolidone in the slurry is 0.2wt%, and then mold the mold at a rate of 10cm / h Immerse in a constant temperature alcohol bath at -10°C at a high speed. After the slurry is completely solidified, quickly transfer it to a freeze dryer, and freeze-dry at -5°C with a final vacuum of 5Pa. The thickness of the sheets is 500 nm, and the distance between adjacent sheets is 10 μm.

[0029] Pre-shaping of carbon nanotube block material: place the above-mentioned carbon nanotube block material between two highly flat stainless steel ingots, and place the direction so that the layer direction of the carbon nanotube block material is parallel to the stainless steel plane. The above-mentioned carbon nanotube bulk material is then compressed along the direction perpendicular to the sheets.

Embodiment 3

[0032] Preparation of sheet-like carbon nanotube bulk material: inject 3wt% carbon nanotube aqueous slurry into the designed mold, the mass fraction of polyvinylpyrrolidone in the slurry is 0.7wt%, and then mold the mold at a rate of 5cm / h Immerse in a constant temperature alcohol bath at -30°C at a high speed. After the slurry is completely solidified, quickly transfer it to a freeze dryer, and freeze-dry at 0°C with a final vacuum of 10Pa. The thickness of the sheets is 45 μm, and the distance between adjacent sheets is 2 μm.

[0033] Pre-shaping of carbon nanotube block material: place the above-mentioned carbon nanotube block material between two highly flat stainless steel ingots, and place the direction so that the layer direction of the carbon nanotube block material is parallel to the stainless steel plane. The above-mentioned carbon nanotube bulk material is then compressed along the direction perpendicular to the sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com