Polar plate treating device

A plate treatment and plate technology, applied in the direction of lead-acid battery electrodes, electrical components, circuits, etc., can solve the problems of low quality, increased cost, long cleaning time, etc., achieve neat and standardized removal, reduce labor intensity, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

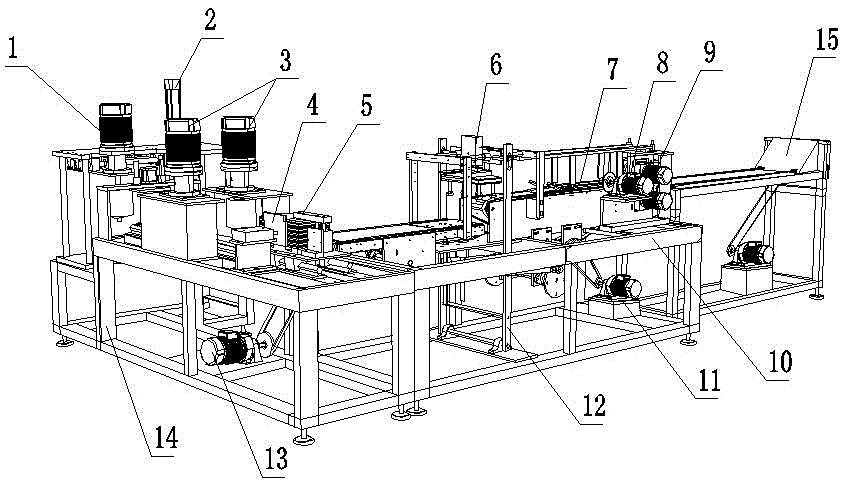

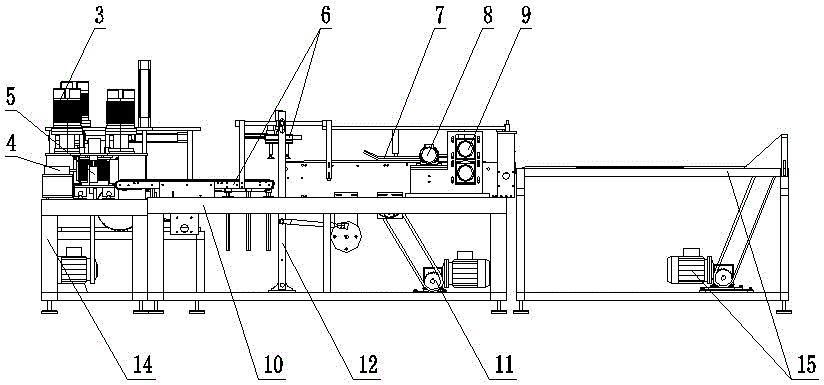

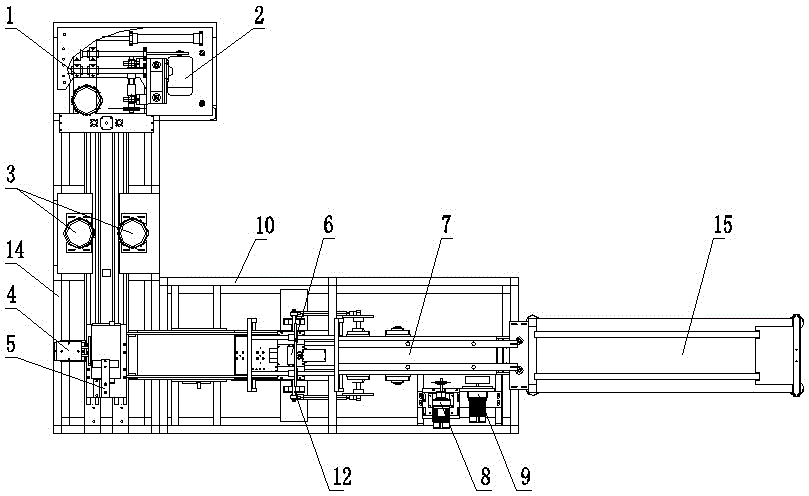

[0038] Such as figure 1 , figure 2 , image 3 As shown, a pole plate processing device includes a longitudinal frame 14, a process lug removal device 2, a pole plate front end cleaning device 1, a pole plate clamping device 5, a longitudinal transport device 13, a pole plate pushing device 4, Plate left and right cleaning device 3, horizontal frame 10, horizontal transport device 11, plate slicing device 6, swing rod device 12, plate pressing device 7, conductive lug removal device 8, rear end cleaning of the plate Device 9; the front end of the longitudinal frame 14 is equipped with a process lug removal device 2 and a front end cleaning device 1 for removing the process lug and cleaning and scraping the front end of the plate. The longitudinal frame 14 The left and right brushing devices 3 for cleaning the left and right sides of the pole plate and the pole plate clamping device 5 for clamping the pole plate stack are installed on the top, and the longitudinal transport d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com