Battery pack frame

A battery pack and frame technology, applied in the field of new energy electric vehicle battery packs, can solve problems such as airtight deterioration, adhesives that cannot be spread, and inspection difficulties, so as to reduce development, facilitate installation and disassembly, and increase energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

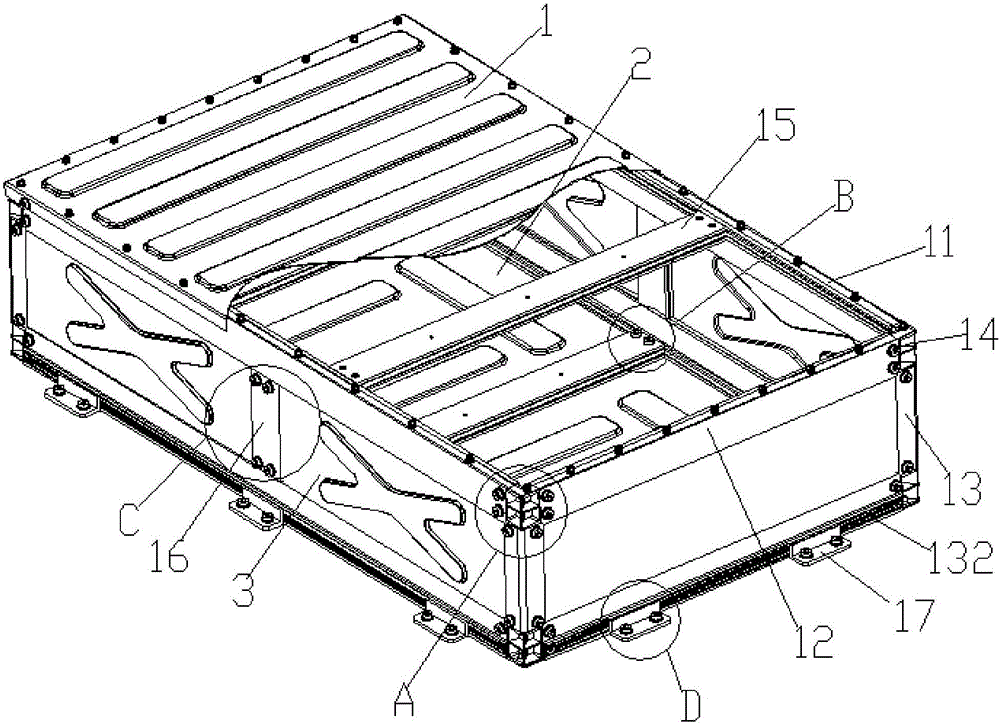

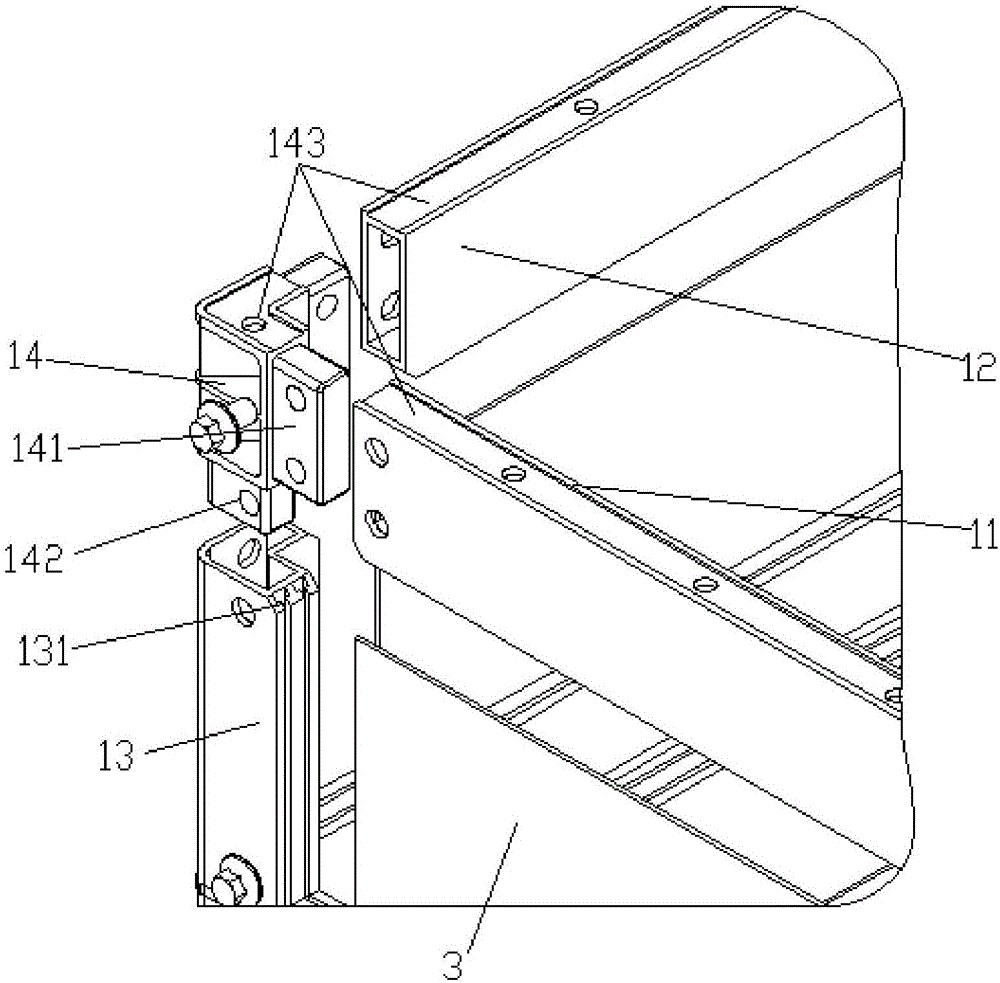

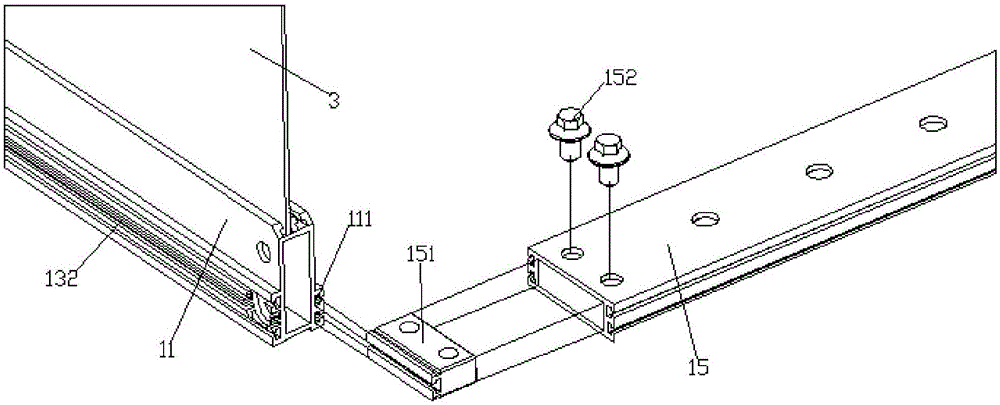

[0025] as attached figure 1 , 2 As shown, the battery pack frame of the present invention includes a movable plug-in frame body for placing battery components, a cover plate 1, a bottom plate 2, and side plates 3 on the front, rear, left, and right sides; the movable plug-in frame body It is mainly composed of several straight beams 11, straight longitudinal beams 12, and straight vertical beams 13, which are spliced together through corner connectors 14. The straight beams 11, straight longitudinal beams 12, and straight vertical beams 13 are all made of extruded aluminum profiles; the corner connectors 14 are castings, and the side plates 3 are plugged into the four-sided side frame of the combination of the straight beams 11 and the straight vertical beams 13. The bottom plate 2 It is plugged into the lower frame of the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com