Gas circuit breaker with reinforced insulation recovery function

A gas circuit breaker and recovery function technology, applied in the field of gas circuit breakers with enhanced insulation recovery function, can solve the problems of insulation capacity decline, insulation cylinder gas pressure fluctuations, etc., achieve uniform density, speed up the insulation recovery rate, and benefit The effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

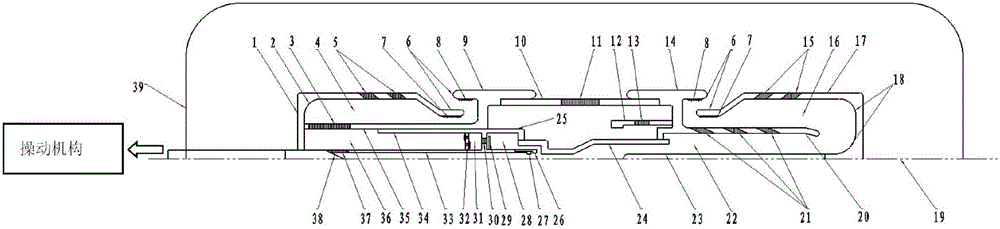

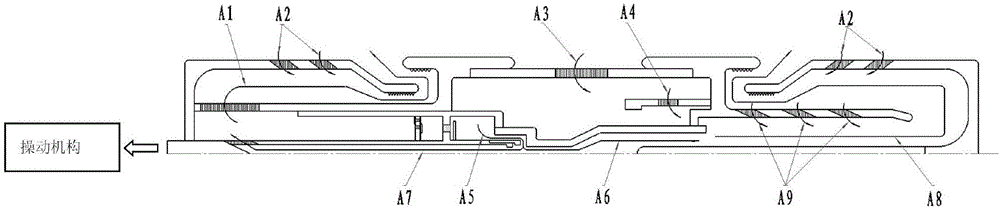

[0078] See figure 1 with figure 2 , The gas circuit breaker with enhanced insulation recovery function of the present invention includes the following functional components: dynamic side support base 1, static side support base 17, insulation cylinder 10, static side main contact 12, dynamic side main contact Head 25, insulating cylinder support seats 9 and 14, moving arc contact 27, static arc contact 23, cylinder barrel 34, main nozzle 24, auxiliary nozzle 26, expansion chamber 28, compressor chamber 31, pressure relief valve 32, moving side The guide tube 35, the static side guide tube 20, the tie rod 33 and the circuit breaker housing 39.

[0079] When the circuit breaker breaks a large current, the tie rod 33 pulls the cylinder barrel 34 to move for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com