High-speed rail fastener detection and counting method and system based on machine vision

A technology of machine vision and fasteners, which is applied to railway car body parts, instruments, calculations, etc., can solve the problems of positioning system installation errors, accumulation of positioning errors, and insufficient accuracy, and achieve high positioning accuracy, rapid response, The effect of no cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

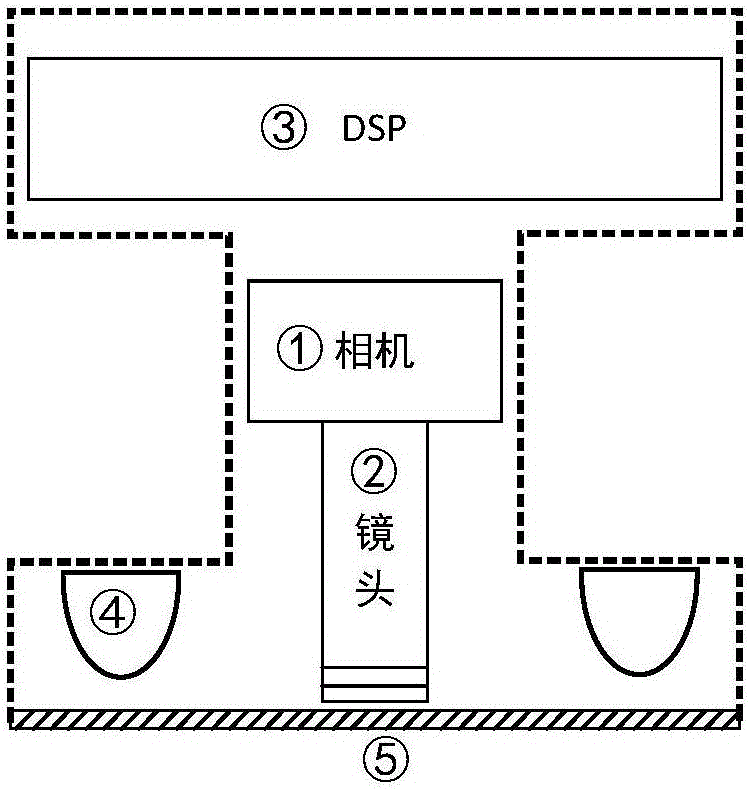

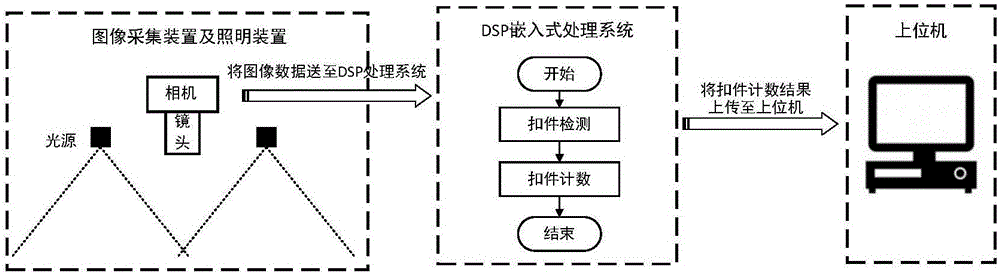

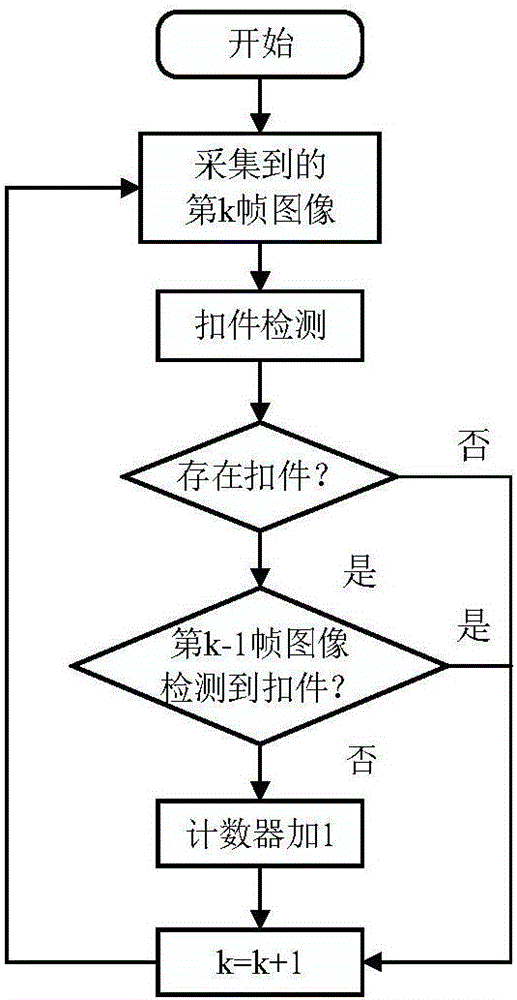

[0042] Such as figure 1 It shows that the system is mounted on the track inspection trolley through the bracket. After the power is turned on, the system is in standby mode, and the LED lighting devices located on both sides of the lens at the lower part of the chassis start to work. When the host computer sends a start signal to the DSP embedded system located on the upper part of the chassis through the RS232 serial port, the system starts to work, and the image acquisition device (camera 1 and lens 2) located in the center of the chassis begins to continuously capture image data. Through the data line of the BNC interface, Send the image data to the DSP embedded processing system, use the fastener detection algorithm to complete the fastener detection, and then use the proposed fastener counting method to complete the counting of the fasteners, and finally sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com