Vibration-proof hammer fault online detection and identification method based on binocular vision image

A technology of binocular vision and recognition method, which is applied in the field of anti-vibration hammer detection, and can solve the problems of transmission line life, transmission corridor safety threat, damage, shedding fault, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

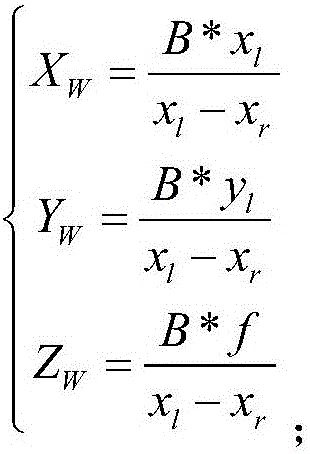

[0099] A method for online detection and identification of anti-vibration hammer faults based on binocular vision images, comprising the following steps:

[0100] Two cameras are used to form a binocular stereo vision system;

[0101] Establish a set S of anti-vibration hammer status attributes;

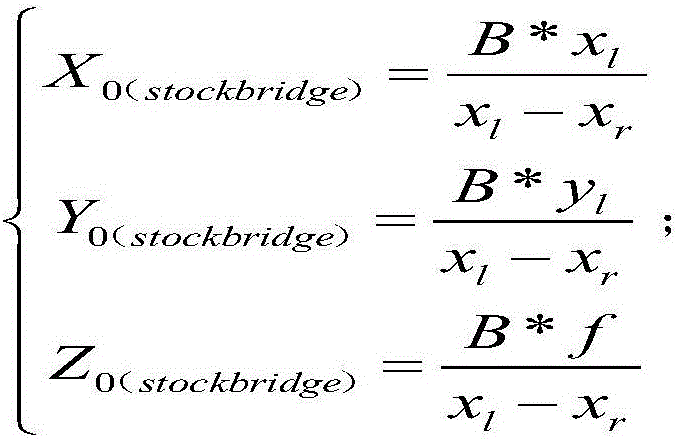

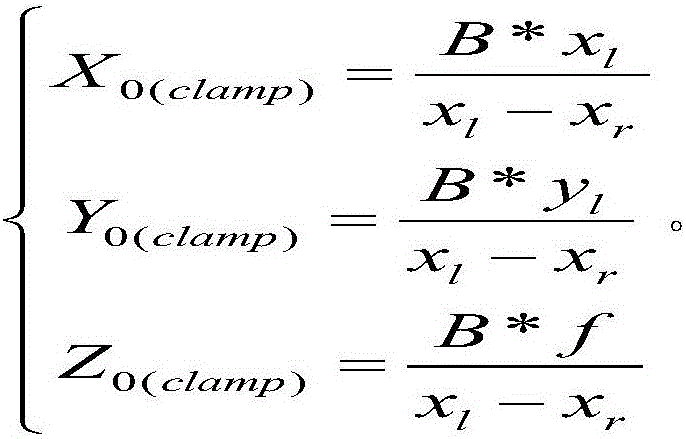

[0102] In the initial state, use two cameras to obtain the initial image information with the anti-vibration hammer and the fixed reference object, and obtain the three-dimensional coordinates of the anti-vibration hammer and the three-dimensional coordinates of the fixed reference object through the initial image information to obtain the state attribute set of the anti-vibration hammer The initial value S of S 0 ;

[0103] In the current state, the abnormal fault detection of the anti-vibration hammer, when the abnormal fault of the anti-vibration hammer is found, two cameras are used to obtain the current image information of the anti-vibration hammer and the fixed reference obj...

Embodiment 2

[0108] On the basis of the above embodiments, preferably, since the anti-vibration hammer often has displacement faults, damage faults, shedding faults, and foreign matter interference faults, the state attributes of the anti-vibration hammer we designed are related to the above faults, and the specific expressions are as follows: The anti-vibration hammer state attribute set S includes ι, m, r, n; ι represents the distance between the anti-vibration hammer and the fixed reference object (can represent a displacement fault); m represents the number of iron hammers of an anti-vibration hammer, Under normal circumstances, an anti-vibration hammer has two hammers (which can indicate a damage failure); r indicates the distance from the disturbing object to the anti-vibration hammer (can indicate a foreign object interference failure); n indicates the number of anti-vibration hammers in a certain section of overhead line (It can indicate a shedding fault); then the initial value S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com